Graphene-modified rubber and preparation method and application thereof

A graphene modification, graphene technology, applied in the field of rubber, to achieve strong anti-burning ability, easy to implement, and ensure the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

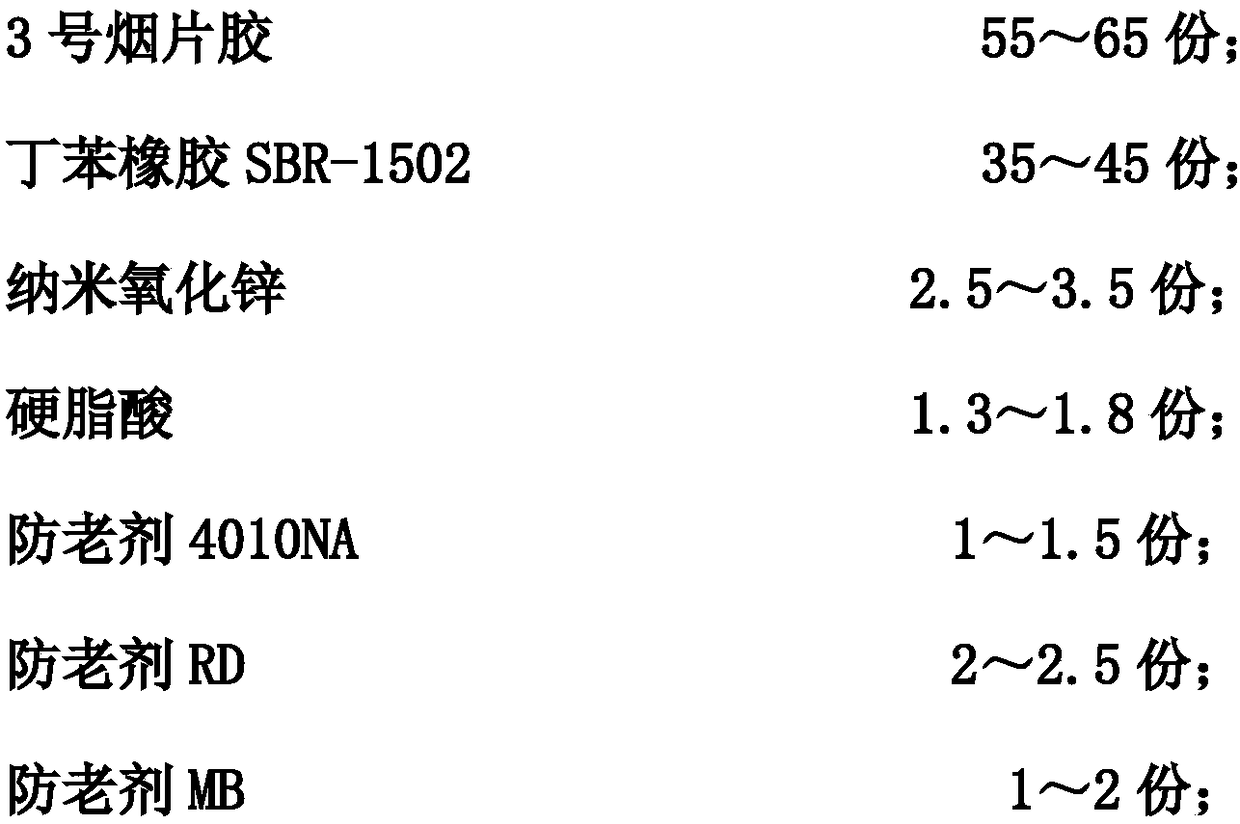

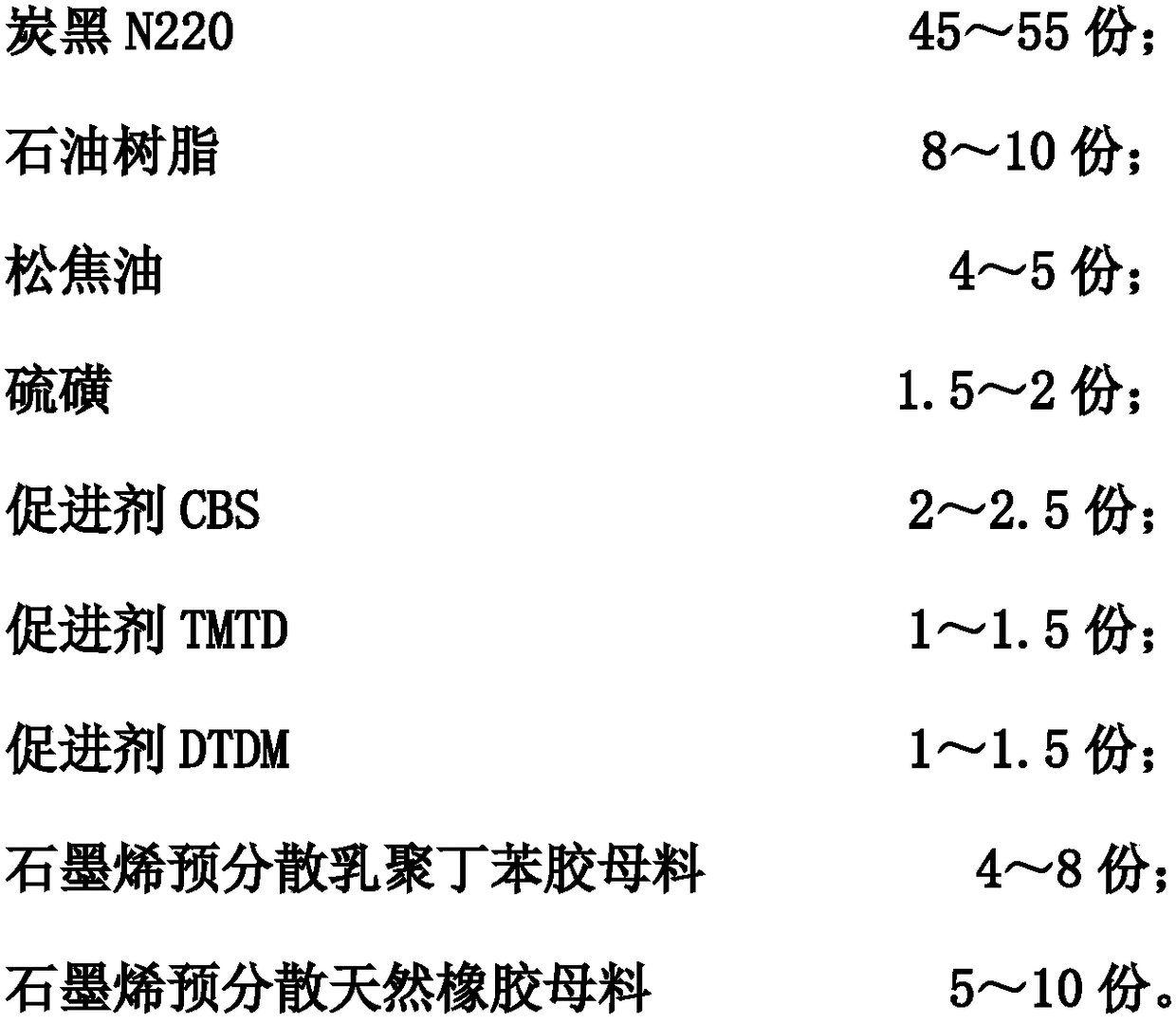

Method used

Image

Examples

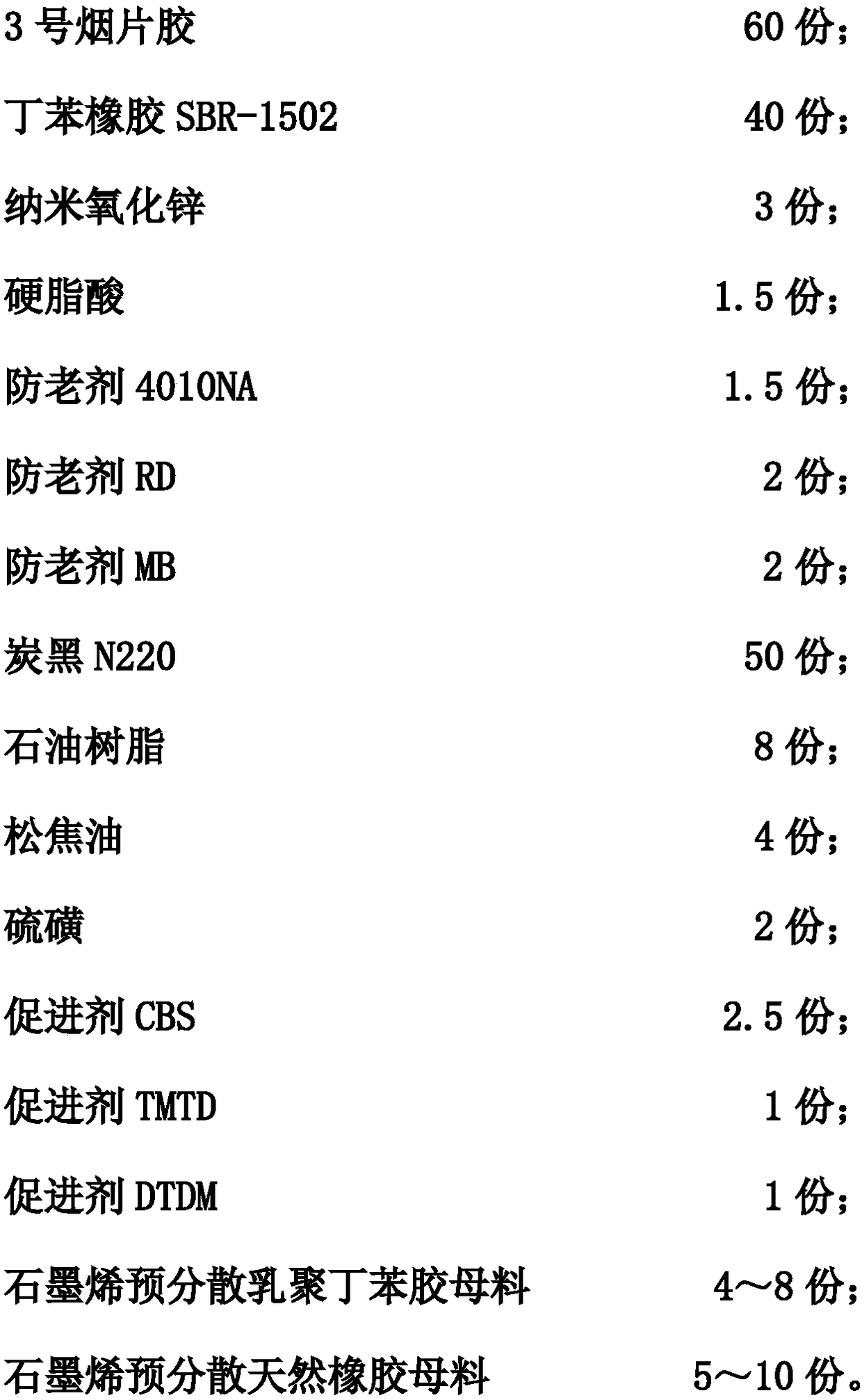

Embodiment 1

[0059] In this example, the graphene-modified rubber is prepared according to the following composition ratio: 60 parts of No. 3 smoked sheet rubber, 240 parts of styrene-butadiene rubber SBR-150, 3 parts of nano-zinc oxide, 1.5 parts of stearic acid, and 1.5 parts of anti-aging agent 4010NA 2 parts of anti-aging agent RD, 2 parts of anti-aging agent MB, 50 parts of carbon black N220, 8 parts of petroleum resin, 4 parts of pine tar, 2 parts of sulfur, 2.5 parts of accelerator CBS, 1 part of accelerator TMTD, 1 part of accelerator DTDM, 5 parts of graphene pre-dispersed emulsion polystyrene butadiene rubber masterbatch, 10 parts of graphene pre-dispersed natural rubber masterbatch.

[0060] Wherein, in the described graphene pre-dispersed EPSBR master batch and graphene pre-dispersed natural rubber master batch, the content of graphene is 10wt%.

[0061] In the present embodiment, graphene-modified rubber is made according to the following steps:

[0062] S1, using an open mil...

Embodiment 2

[0075] The difference from Example 1 is that in this example, the graphene-modified rubber is prepared according to the following component ratios: 60 parts of No. 3 smoke sheet rubber, 40 parts of styrene-butadiene rubber SBR-1502, 3 parts of nano-zinc oxide, 1.5 parts of stearic acid, 1.5 parts of anti-aging agent 4010NA, 2 parts of anti-aging agent RD, 2 parts of anti-aging agent MB, 50 parts of carbon black N220, 8 parts of petroleum resin, 4 parts of pine tar, 2 parts of sulfur, 2.5 parts of accelerator CBS, 1 part of accelerator TMTD, 1 part of accelerator DTDM, 4 parts of graphene pre-dispersed emulsion polystyrene butadiene rubber masterbatch, 5 parts of graphene pre-dispersed natural rubber masterbatch.

Embodiment 3

[0077] The difference from Example 1 is that in this example, the graphene-modified rubber is prepared according to the following component ratios: 60 parts of No. 3 smoke sheet rubber, 40 parts of styrene-butadiene rubber SBR-1502, 3 parts of nano-zinc oxide, 1.5 parts of stearic acid, 1.5 parts of anti-aging agent 4010NA, 2 parts of anti-aging agent RD, 2 parts of anti-aging agent MB, 50 parts of carbon black N220, 8 parts of petroleum resin, 4 parts of pine tar, 2 parts of sulfur, 2.5 parts of accelerator CBS, 1 part of accelerator TMTD, 1 part of accelerator DTDM, 8 parts of graphene pre-dispersed emulsion polystyrene butadiene rubber masterbatch, 10 parts of graphene pre-dispersed natural rubber masterbatch.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| wear volume | aaaaa | aaaaa |

| wear volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com