Composite material with anion biomimetic function and production method thereof

A bionic function and composite material technology, applied in one field, can solve the problems of high cost and expense, side effects, and short life of the instrument

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

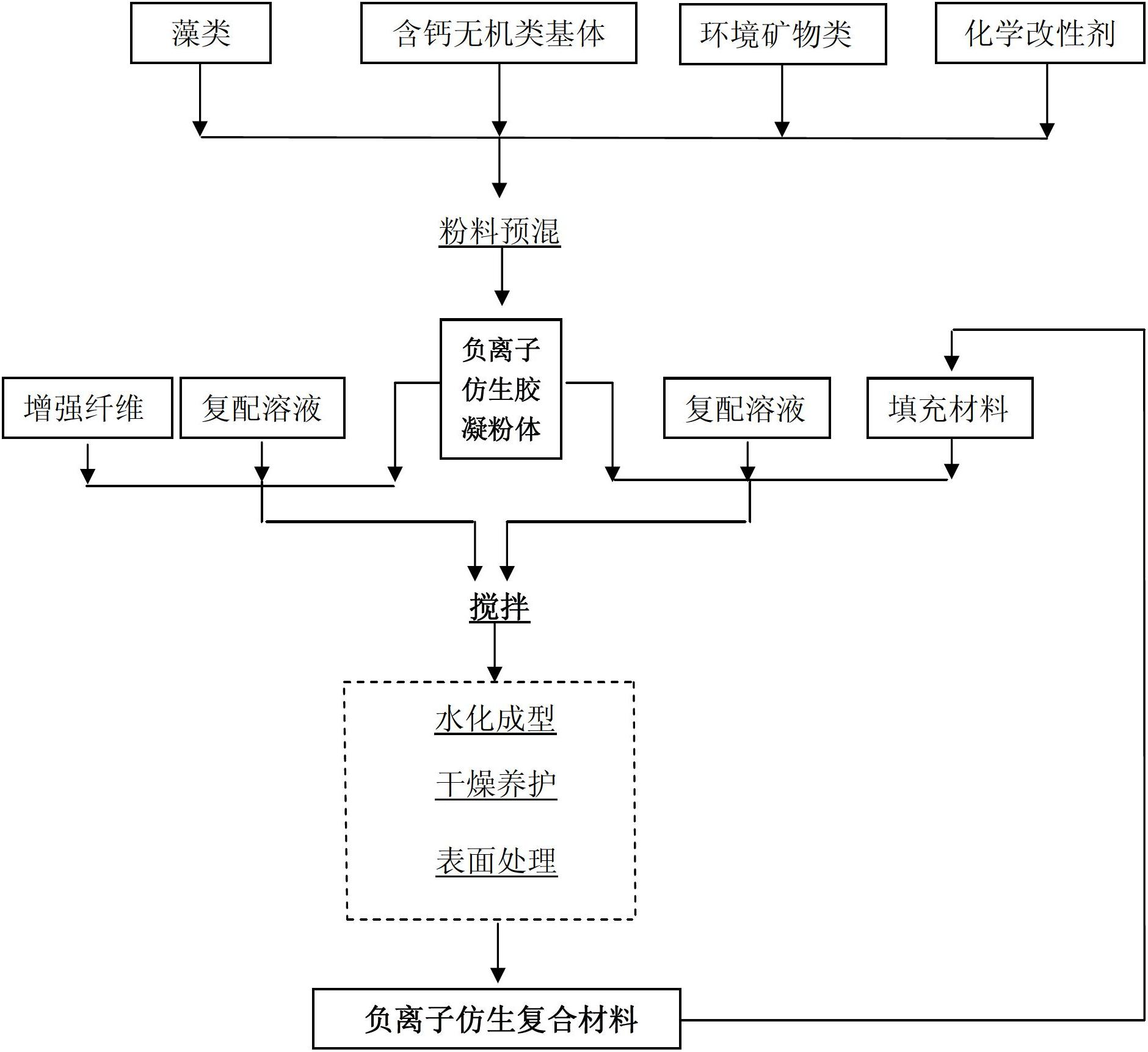

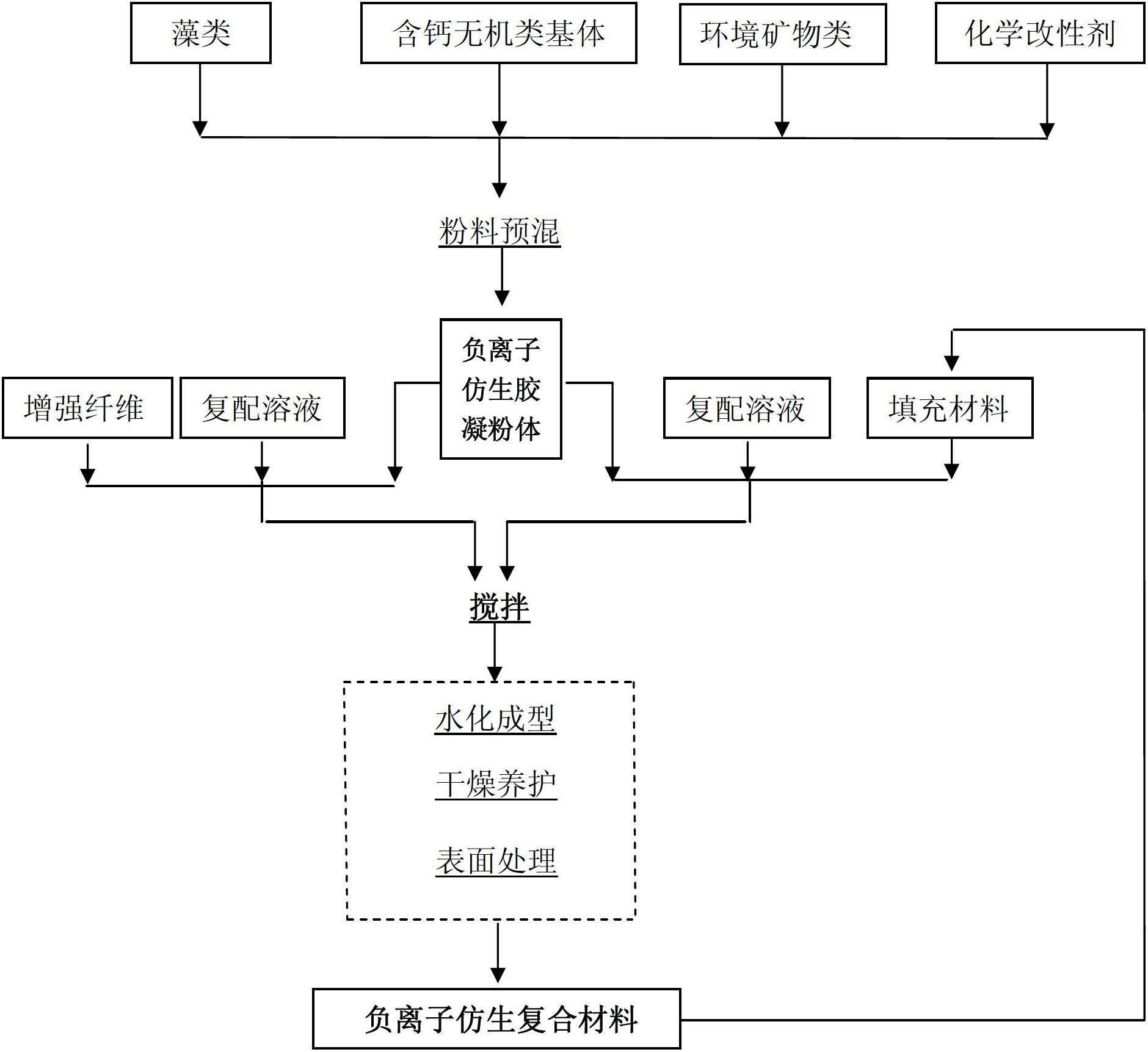

Method used

Image

Examples

Embodiment 1

[0047] Example 1: A gelled powder with negative ion biomimetic function

[0048] 1. Formula composition (substances are measured in parts by weight):

[0049] (1) 41 parts of natural β-calcium sulfate hemihydrate;

[0050] (2) Diatomite: 12 parts of ground diatomite powder with a particle size of 400-800 mesh;

[0051] (3) Inorganic environmental minerals: 4 parts of seagull stone powder

[0052] (4) Modifier: 2 parts of compound powder uniformly mixed with 54% calcium oxide, 36% silicon oxide and 10% polyvinyl alcohol;

[0053] 2. Production and preparation process:

[0054] (1) Pretreatment of raw materials: β-calcium sulfate hemihydrate, diatomaceous earth, seagull stone powder, and modifiers are accurately measured according to 41 parts, 12 parts, 4 parts, and 2 parts respectively;

[0055] (2) After pre-mixing, it is prepared by aging in an aging warehouse for 3-15 days.

Embodiment 2

[0056] Embodiment 2: A kind of decorative plate with negative ion bionic function

[0057] 1. Formula composition (substances are measured in parts by weight):

[0058] (1) 47.8 parts of calcium phosphate;

[0059] (2) Diatomite: 10 parts of ground diatomite powder with a particle size of 400-800 mesh;

[0060] (3) Inorganic environmental minerals: 2 parts of seagull stone powder

[0061] (4) Modifier: 2 parts of compound powder uniformly mixed with 60% calcium oxide, 32% silicon oxide and 8% polyvinyl alcohol;

[0062] (5) Reinforced fiber chopped strands: 0.2 parts of glass fiber with a length of 18-20 mm;

[0063] (6) Composite solution: clear water, crystal modifier, waterproofing agent, and defoamer are mixed and stirred according to their mass ratio of 100:1.8:0.4:0.5 to form 38 parts of a uniform composite solution; the crystal modifier is Sodium citrate; The waterproofing agent is sodium methyl siliconate; The defoamer is tributyl phosphate.

[0064] 2. Production...

Embodiment 3

[0070] Embodiment 3: A kind of filler with negative ion biomimetic function

[0071] 1. Formula composition (substances are measured in parts by weight):

[0072] (1) 47 parts of calcium aluminate;

[0073] (2) Seaweed earth: 8 parts of seaweed earth powder with a particle size of 400-800 mesh and ground;

[0074] (3) Inorganic environmental minerals: 6 parts of tourmaline powder

[0075] (4) Modifier: 2 parts of compound powder uniformly mixed with 54% calcium oxide, 36% silicon oxide and 10% polyvinyl alcohol;

[0076] (5) Reinforced fiber chopped strands: 1.0 parts of mineral fiber with a length of 8-12 mm;

[0077] (6) Composite solution: clear water, crystal modifier, waterproofing agent, and defoamer are mixed and stirred according to their mass ratio of 100:1.8:0.4:0.5 to form 36 parts of a uniform composite solution; the crystal modifier is Aluminum potassium sulfate; Described waterproof agent is siloxane; Described defoamer is isoamyl alcohol.

[0078] 2. Produc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com