Upward-drawing type dense-lean burner

A technology of thick-lean combustion and burners, which is applied in the direction of burners, gas fuel burners, and combustion methods. Low cost and easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

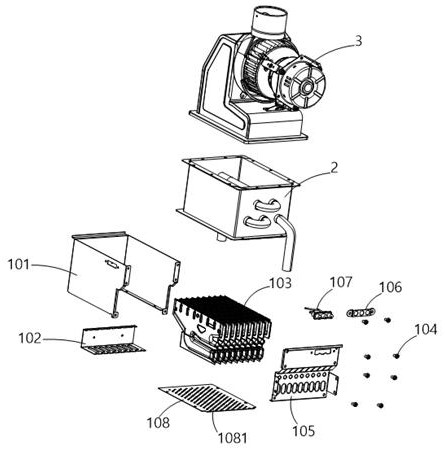

[0057] When in use, the air in the external environment or other introduced gases will enter the thin air inlet 10311 and the rich air inlet 10312 on the single-piece burner 1031 in the burner assembly 1 at the same time, and the gas entering the thin air inlet 10311 reaches the single-piece The auxiliary flame port 10313 on the top of the burner 1031, the gas entering the thick gas inlet 10312 reaches the main flame port 10314 on the top of the single-chip burner 1031, the auxiliary flame port 10313 is symmetrically arranged on both sides of the main flame port 10314, but the main flame port 10314 burns The flame emitted by the secondary flame ports 10313 on both sides is relatively higher, and the combustion process of the gas is realized.

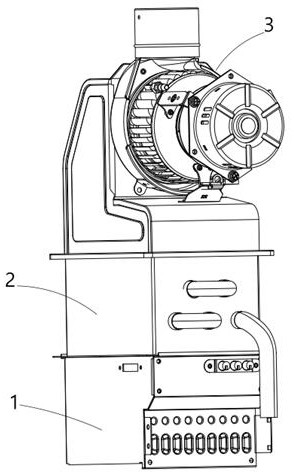

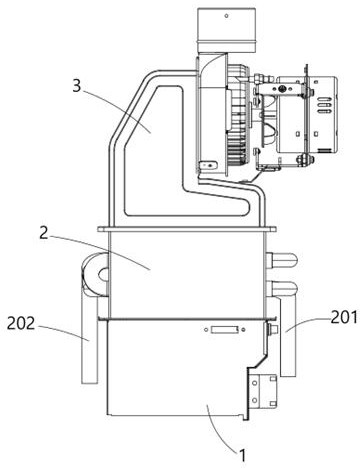

[0058] In the above-mentioned combustion process, a heat exchanger 2 is arranged above the burner assembly 1, and a water inlet 201 and a water outlet 202 are arranged in the heat exchanger 2, which can not only cool the burner assembly 1...

Embodiment 2

[0060] In this embodiment, on the basis of the first embodiment above, a thick-thin air intake adjustment device is added on the side of the combustion sheet group 103. The thick-thin air intake adjustment device includes the operation panel 4 and its related structures. When needed, the first The sealing joint pipes 500 are aligned with the light air inlets 10311 one by one, the second sealing joint pipes 100 are aligned with the rich air inlets 10312 one by one, and then the thick and thin air inlet adjustment device is inserted into the side of the combustion plate group 103 as a whole, the first sealing Both the joint pipe 500 and the second sealing joint pipe 100 can be selected from pipes with certain elasticity and good sealing performance.

[0061] When in use, the external air first enters the communication groove 15 through the filter screen 16, and the filter screen 16 blocks the dust in the external air to prevent dust from adhering to and polluting the ventilation ...

Embodiment 3

[0064] This embodiment is similar to Embodiment 2, the only difference is that in this embodiment, the bottom wall of the inner tube of the first hose section 701 and the top wall of the inner tube of the second hose section 121 are fixedly provided with mounting plates 22. The side of the mounting plate 22 is fixedly provided with an inner tube cleaning brush 23 .

[0065]When the first hose section 701 and the second hose section 121 are squeezed, the mounting plate 22 will be pushed, and the mounting plate 22 at this time will drive the inner tube cleaning brush 23, and at the same time clean the first hose section 701 and the second hose section 701. The inner pipe wall of the second hose section 121 is cleaned to avoid the problem of adhesion and adhesion caused by long-term non-cleaning of the tiny dust infiltrated from the filter screen 16 after adhering to the above-mentioned inner pipe wall. After a long period of use, it is disassembled and cleaned, thereby prolongin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com