A silicon chip grafted with polyionic liquid and its preparation method and application

A technology of polyionic liquids and silicon wafers, applied in chemical instruments and methods, material separation, and other chemical processes, can solve problems such as poor results, and achieve the effects of short operation time, strong adsorption capacity, and reduced dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

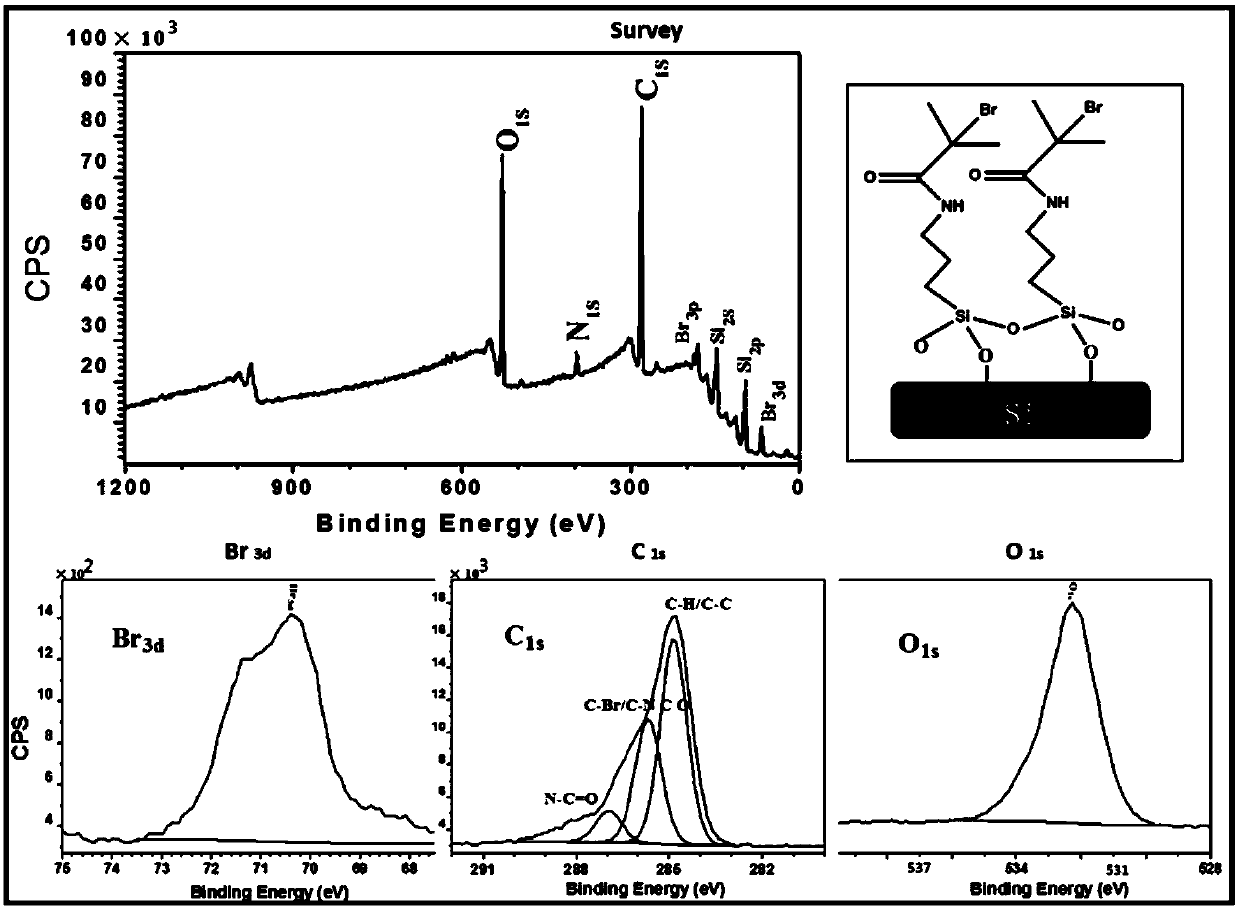

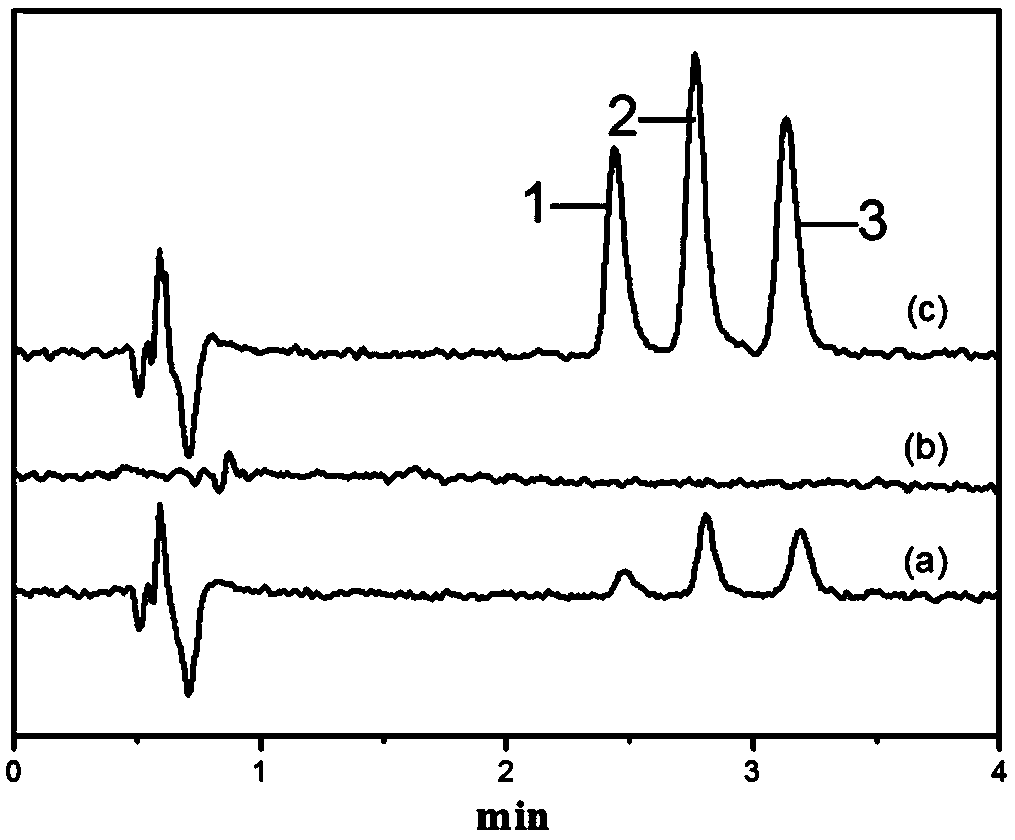

Method used

Image

Examples

specific Embodiment 1

[0035] The preparation method of the silicon wafer grafted with polyionic liquid disclosed in this embodiment is characterized in that it comprises the following steps:

[0036] 1) The specific process of silicon wafer surface modification treatment is as follows:

[0037]1-1) Cleaning the silicon wafer: Put the cut silicon wafer into the ethanol solution for 5 minutes, rinse it with deionized water, and then use the concentrated sulfuric acid:hydrogen peroxide solution with a volume ratio of 7:3 for 10 minutes before using it. Rinse with deionized water, then sonicate with deionized water for 10 minutes, and finally use 5% hydrofluoric acid solution for 10 minutes, then rinse with deionized water, then use deionized water for 5 minutes, and put them in ethanol solution for storage.

[0038] 1-2) Hydroxylation treatment: place the silicon wafer described in step 1-1) in 0.1mol·L -1 Soak in sodium hydroxide solution (0.2g sodium hydroxide, 50ml deionized water) for 8 minutes, ...

specific Embodiment 2

[0045] The preparation method of the silicon wafer grafted with polyionic liquid disclosed in this embodiment is characterized in that it comprises the following steps:

[0046] 1) The specific process of silicon wafer surface modification treatment is as follows:

[0047] 1-1) Cleaning the silicon wafer: Put the cut silicon wafer into the ethanol solution for 5 minutes, rinse it with deionized water, and then use the concentrated sulfuric acid:hydrogen peroxide solution with a volume ratio of 7:3 for 10 minutes before using it. Rinse with deionized water, then sonicate with deionized water for 10 minutes, and finally use 5% hydrofluoric acid solution for 10 minutes, then rinse with deionized water, then use deionized water for 5 minutes, and put them in ethanol solution for storage.

[0048] 1-2) Hydroxylation treatment: place the silicon wafer described in step 1-1) in 0.1mol·L -1 Soak in sodium hydroxide solution (0.2g sodium hydroxide, 50ml deionized water) for 9min, rins...

specific Embodiment 3

[0054] The preparation method of the silicon wafer grafted with polyionic liquid disclosed in this embodiment is characterized in that it comprises the following steps:

[0055] 1) The specific process of silicon wafer surface modification treatment is as follows:

[0056] 1-1) Cleaning the silicon wafer: Put the cut silicon wafer into the ethanol solution for 5 minutes, rinse it with deionized water, and then use the concentrated sulfuric acid:hydrogen peroxide solution with a volume ratio of 7:3 for 10 minutes before using it. Rinse with deionized water, then sonicate with deionized water for 10 minutes, and finally use 5% hydrofluoric acid solution for 10 minutes, then rinse with deionized water, then use deionized water for 5 minutes, and put them in ethanol solution for storage.

[0057] 1-2) Hydroxylation treatment: place the silicon wafer described in step 1-1) in 0.1mol·L -1 Soak in sodium hydroxide solution (0.2g sodium hydroxide, 50ml deionized water) for 10min, rin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com