A cnfs load mos 2 Magnesium-lithium double-salt battery cathode material and construction method thereof

A battery cathode and nanocomposite material technology is applied in the field of CNFs-supported MoS2 magnesium-lithium double-salt battery cathode material and its construction, which can solve structural instability, reduce battery system capacity, rate characteristics, cycle stability, and insufficient conductivity. and other problems, to achieve the effect of improving battery life, improving capacity and rate characteristics, and improving cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

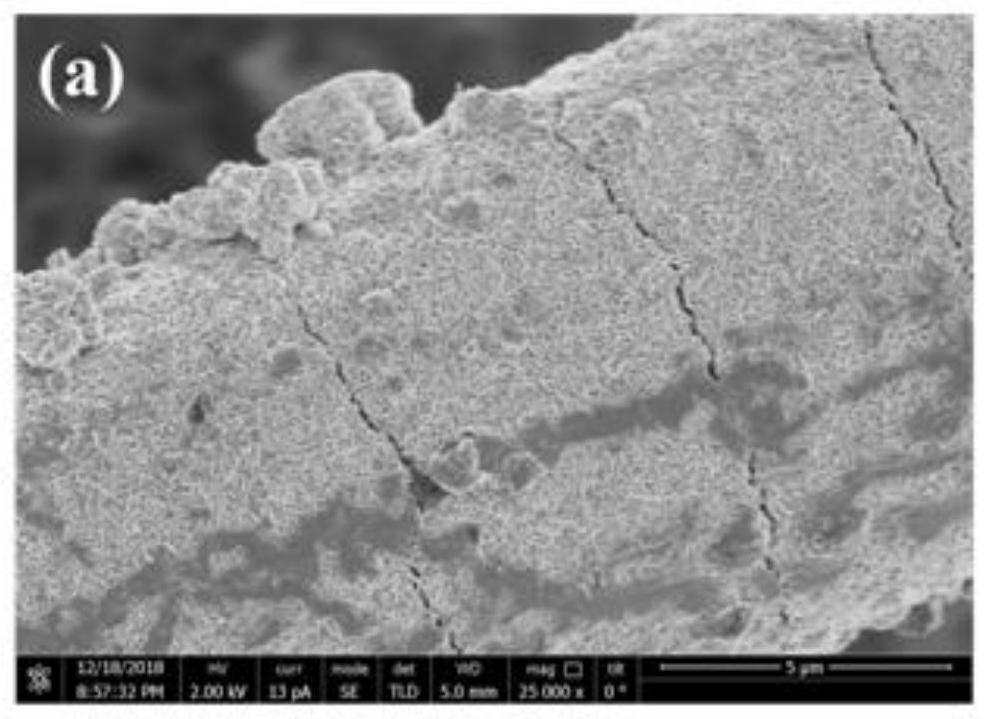

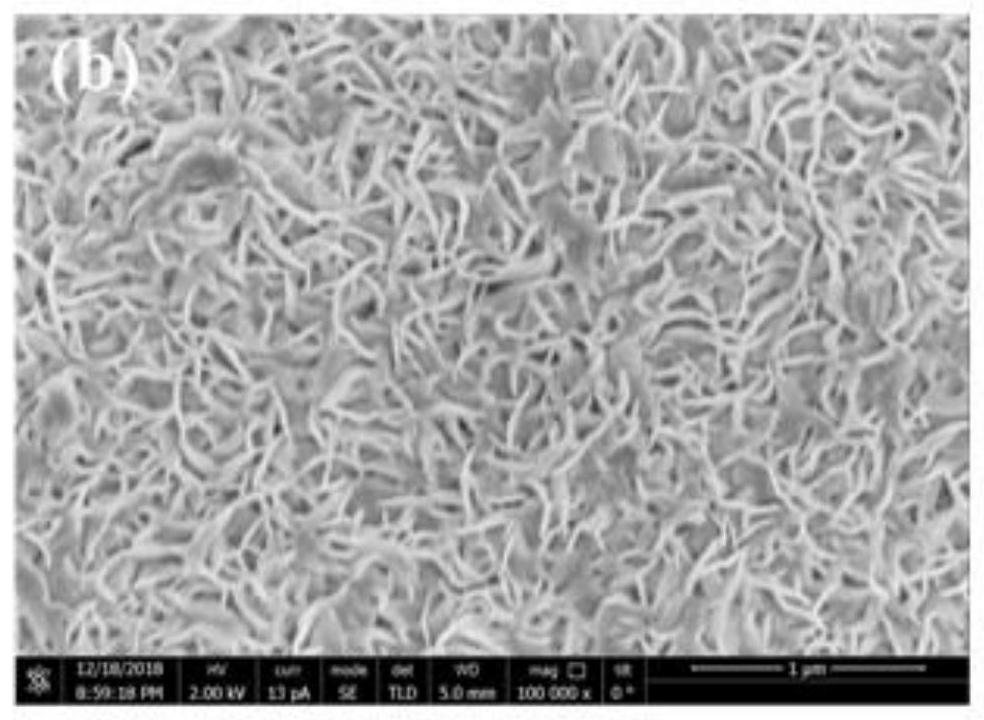

[0030] Step 1, carbon fiber pretreatment: cut a bunch of carbon fiber CNFs with scissors to 5-10mm, disperse and soak in acetone solution, remove oil and other impurities on the surface of CNFs, and improve the surface cleanliness and activity of CNFs;

[0031] Step 2, solution preparation: Weigh 0.80g of sodium molybdate, 0.68g of hydroxylamine hydrochloride and 1.20g of thiourea and dissolve them in 50mL of deionized water;

[0032] Step 3, surfactant addition and pH adjustment: then weigh 0.18g of cetyltrimethylammonium bromide (CTAB) and add it to the solution, adjust the pH of the solution to 6 with 2mol / L of HCL to obtain a solution ;

[0033] Step 4, hydrothermal synthesis: Add the carbon fiber CNFs obtained in step 1 to the solution obtained in step 3 to obtain a hydrothermal solution, stir the above hydrothermal solution for 1 hour, transfer it to a 100mL hydrothermal reaction kettle, and react The kettle was placed in an oven and reacted at 180°C for 24h.

[0034] ...

Embodiment 2

[0036] Step 1, carbon fiber pretreatment: cut a bunch of carbon fiber CNFs with scissors to 5-10mm, disperse and soak in acetone solution, remove oil and other impurities on the surface of CNFs, and improve the surface cleanliness and activity of CNFs;

[0037] Step 2, solution preparation: Weigh 0.68g of sodium molybdate, 0.525g of hydroxylamine hydrochloride and 1.0g of thiourea and dissolve them in 50mL of deionized water;

[0038] Step 3, surfactant addition and pH adjustment: then weigh 0.18g of cetyltrimethylammonium bromide (CTAB) and add it to the solution, adjust the pH of the solution to 6 with 2mol / L of HCL to obtain a solution ;

[0039] Step 4, hydrothermal synthesis: Add the carbon fiber CNFs obtained in step 1 to the solution obtained in step 3 to obtain a hydrothermal solution, stir the above hydrothermal solution for 1 hour, transfer it to a 100mL hydrothermal reaction kettle, and react The kettle was placed in an oven and reacted at 180°C for 24h.

[0040] St...

Embodiment 3

[0042] Step 1, carbon fiber pretreatment: cut a bunch of carbon fiber CNFs with scissors to 5-10mm, disperse and soak in acetone solution, remove oil and other impurities on the surface of CNFs, and improve the surface cleanliness and activity of CNFs;

[0043] Step 2, solution preparation: Weigh 0.88g of sodium molybdate, 0.825g of hydroxylamine hydrochloride and 1.60g of thiourea and dissolve them in 50mL of deionized water;

[0044] Step 3, surfactant addition and pH adjustment: then weigh 0.18g of cetyltrimethylammonium bromide (CTAB) and add it to the solution, adjust the pH of the solution to 6 with 2mol / L of HCL to obtain a solution ;

[0045] Step 4, hydrothermal synthesis: Add the carbon fiber CNFs obtained in step 1 to the solution obtained in step 3 to obtain a hydrothermal solution, stir the above hydrothermal solution for 1 hour, transfer it to a 100mL hydrothermal reaction kettle, and react The kettle was placed in an oven and reacted at 180°C for 24h.

[0046]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com