Sodium-ion battery negative electrode material and preparation method and application thereof

A technology of sodium ion battery and negative electrode material, applied in battery electrodes, negative electrodes, secondary batteries, etc., can solve the problems of limited application, low Coulomb efficiency, lack of voltage platform, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

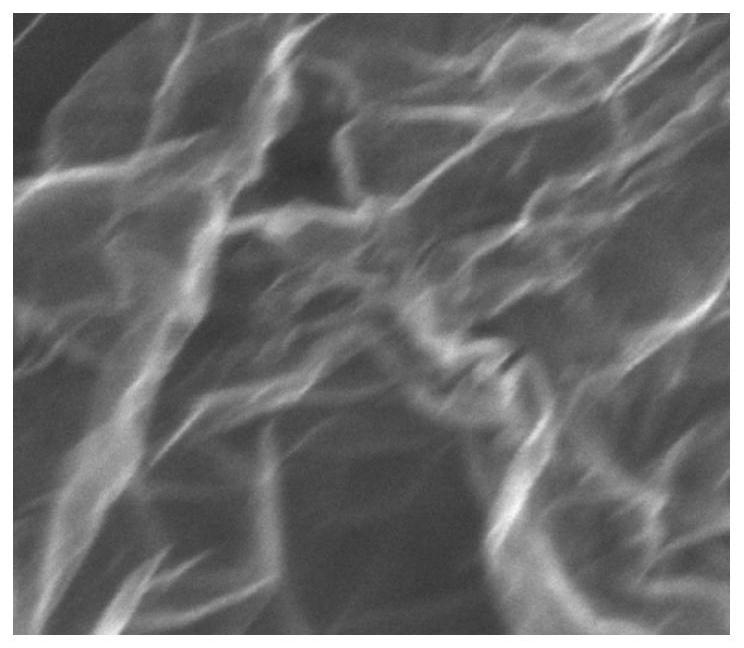

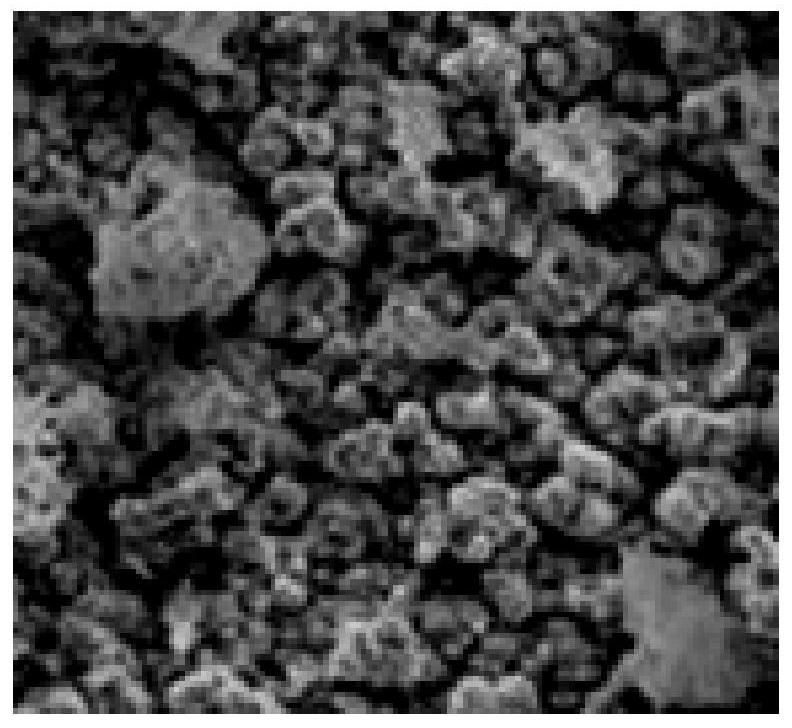

Image

Examples

Embodiment 1

[0042] WS 2 / MoS 2 -Synthesis of G: Sodium molybdate, sodium tungstate and thiourea are added to the graphene oxide solution, wherein (sodium molybdate+sodium tungstate): thiourea:graphene oxide=1:2:0.5, molybdic acid Sodium: sodium tungstate = 1:1, magnetic stirring, stirring for 1h until sodium molybdate and sodium tungstate are fully dissolved in the graphene oxide solution, then transferred to a stainless steel reaction kettle with a polytetrafluoroethylene liner, the temperature is 180 ℃, time 15h, cooling and filtering after reaction, vacuum drying, temperature 95℃, drying time 4h, to obtain WS 2 / MoS 2 -G Standby.

[0043] WS 2 / MoS 2 -Synthesis of G@C: the WS obtained in step 1 2 / MoS 2 -G is blended with petroleum asphalt powder with a softening point of 160°C, WS 2 / MoS 2 -G is mixed with petroleum asphalt powder. The proportion of petroleum asphalt is 30%. After stirring for 5 h, the rotational speed was adjusted to 50 rpm, and the temperature was lowered ...

Embodiment 2

[0046] WS 2 / MoS 2 -Synthesis of G: Sodium molybdate, sodium tungstate and thiourea are added to the graphene oxide solution, wherein (sodium molybdate+sodium tungstate): thiourea:graphene oxide=1:2:0.5, molybdic acid Sodium: sodium tungstate = 1:1, magnetic stirring, stirring for 1h until sodium molybdate and sodium tungstate are fully dissolved in the graphene oxide solution, then transferred to a stainless steel reaction kettle with a polytetrafluoroethylene liner, the temperature is 180 ℃, time 15h, cooling and filtering after reaction, vacuum drying, temperature 95℃, drying time 4h, to obtain WS 2 / MoS 2 -G Standby.

[0047] WS 2 / MoS 2 -Synthesis of G@C: the WS obtained in step 1 2 / MoS 2 -G mixed with petroleum asphalt powder and fused, WS 2 / MoS 2 -G is mixed with petroleum asphalt powder with a softening point of 240°C. The proportion of petroleum asphalt is 30%. Control device, after insulated and stirred for 5 hours, the rotating speed was adjusted to 50 r...

Embodiment 3

[0049] WS 2 / MoS 2 -Synthesis of G: Sodium molybdate, sodium tungstate and thiourea are added to the graphene oxide solution, wherein (sodium molybdate+sodium tungstate): thiourea:graphene oxide=1:2:0.5, molybdic acid Sodium: sodium tungstate = 1:1, magnetic stirring, stirring for 1h until sodium molybdate and sodium tungstate are fully dissolved in the graphene oxide solution, then transferred to a stainless steel reaction kettle with a polytetrafluoroethylene liner, the temperature is 180 ℃, time 15h, cooling and filtering after reaction, vacuum drying, temperature 95℃, drying time 4h, to obtain WS 2 / MoS 2 -G Standby.

[0050] WS 2 / MoS 2 -Synthesis of G@C: the WS obtained in step 1 2 / MoS 2 -G mixed with phenolic resin powder and fused, WS 2 / MoS 2 -G is mixed with phenolic resin powder, the proportion of phenolic resin is 30%, the speed of mixing is 100 rpm, start the temperature control device and raise the temperature to 600 °C at a rate of 50 °C / h, stop the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com