Graphene-coated copper oxide composite cathode material and method for manufacturing same

A graphene-coated, negative electrode material technology, applied in battery electrodes, electrical components, circuits, etc., can solve the problems of poor conductivity and reduced capacity of copper oxide electrodes, improve electrochemical performance, alleviate pulverization, and speed up electronic production. The effect of migration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Weigh 1.7g of CuCl 2 2H 2 O is dissolved in deionized water to form a copper chloride solution with a concentration of 0.1mol / L, and 100ml of a graphene oxide solution with a concentration of 0.17mol / L (the concentration of the graphene oxide solution is calibrated in advance, and the graphene quality in the solution is about Half of the mass of graphene oxide) mixed evenly and stirred for 30 minutes, kept in a constant temperature water bath, set the temperature at 50°C, added dropwise 120ml of sodium hydroxide solution with a concentration of 0.2mol / L and continued to stir at a constant temperature for 1h; after standing for 8h, centrifuged, and then microwaved Auxiliary hydrothermal, the hydrothermal temperature is 180°C, and the hydrothermal time is 1h; finally, it is dried at 120°C for 12h to obtain the graphene-coated copper oxide composite negative electrode material.

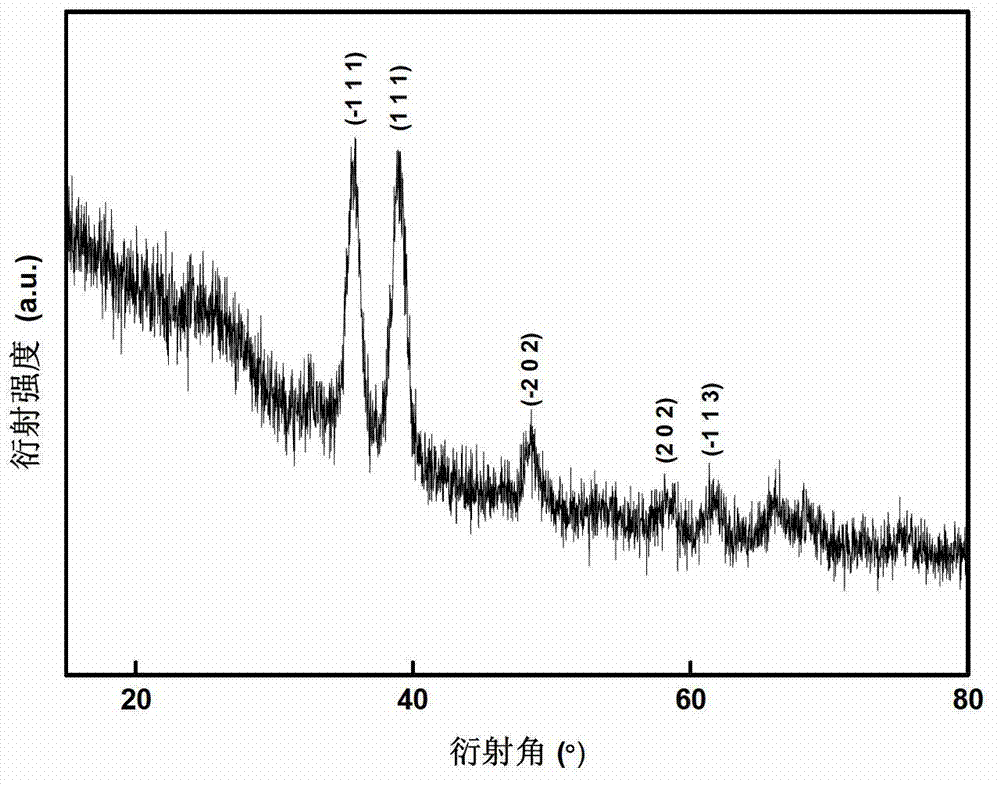

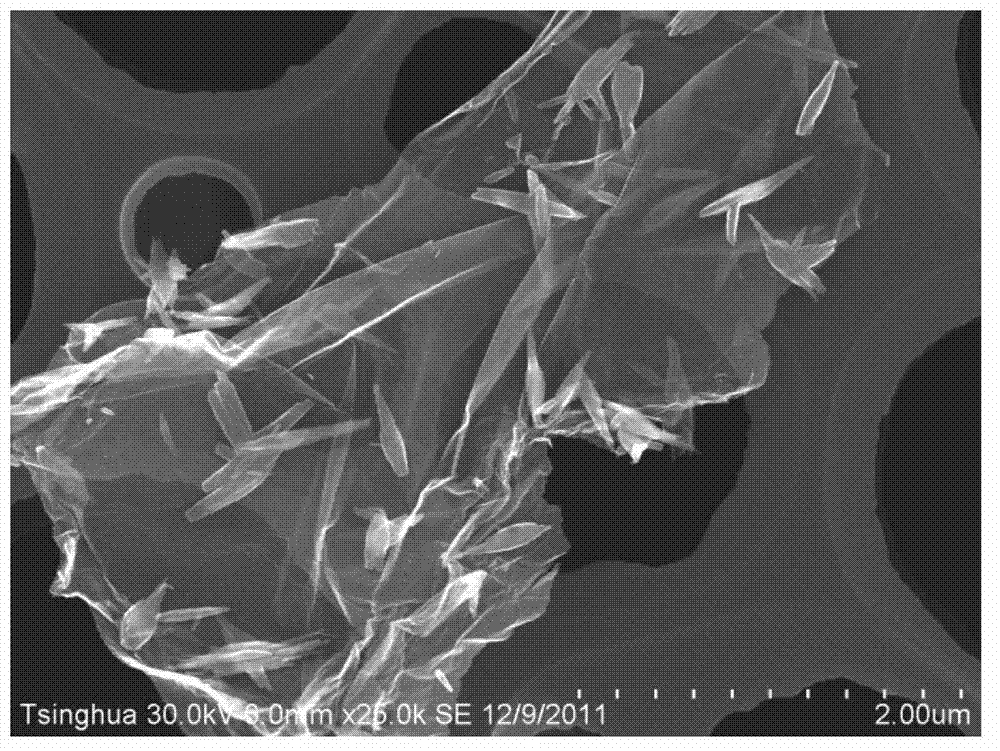

[0019] The mass percentage content of copper oxide in the graphene-coated copper oxide compos...

Embodiment 2

[0021] Weigh 2.7g of Cu(NO 3 ) 2 ·3H 2 O was dissolved in deionized water to prepare a copper nitrate solution with a concentration of 0.113mol / L, mixed with 100ml of a graphene oxide solution with a concentration of 0.083mol / L and stirred for 15min. 140ml of sodium hydroxide solution with a concentration of 0.2mol / L was continuously stirred at a constant temperature for 2 hours; centrifuged after standing for 4 hours, and then microwave-assisted hydroheating was used, the hydrothermal temperature was 160°C, and the hydrothermal time was 30 minutes; finally, it was dried at 120°C for 12 hours to obtain Graphene-coated copper oxide composite anode material.

[0022] The mass percentage content of copper oxide in the graphene-coated copper oxide composite negative electrode material obtained in this embodiment is 90%, and the mass percentage content of graphene is 10%.

Embodiment 3

[0024] Weigh 1.9g of Cu(SO 4 ) 2 ·5H 2 O was dissolved in deionized water to make a copper sulfate solution with a concentration of 0.075mol / L, mixed with 100ml of a graphene oxide solution with a concentration of 0.333mol / L and stirred for 1 hour, kept in a constant temperature water bath, and the temperature was set at 60°C, and added dropwise 90 ml of potassium hydroxide solution with a concentration of 0.2 mol / L was continuously stirred at a constant temperature for 1.5 h; after standing for 12 h, it was centrifuged, and then microwave-assisted hydroheating was used. The hydrothermal temperature was 200 °C and the hydrothermal time was 2 h. Finally, it was dried at 120° C. for 12 hours to obtain a graphene-coated copper oxide composite negative electrode material.

[0025] The mass percent content of copper oxide in the graphene-coated copper oxide composite negative electrode material obtained in this embodiment is 60%, and the mass percent content of graphene is 40%. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com