Preparation method for molybdenum disulfide/carbon microsphere negative electrode material of lithium ion battery

A lithium-ion battery and molybdenum disulfide technology, applied in battery electrodes, secondary batteries, negative electrodes, etc., can solve the problems of poor controllability of material structure and morphology, expensive template method, harsh reaction conditions, etc., and achieve excellent Electrochemical performance and cycle performance, material structure and morphology can be controlled, and the effect of mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

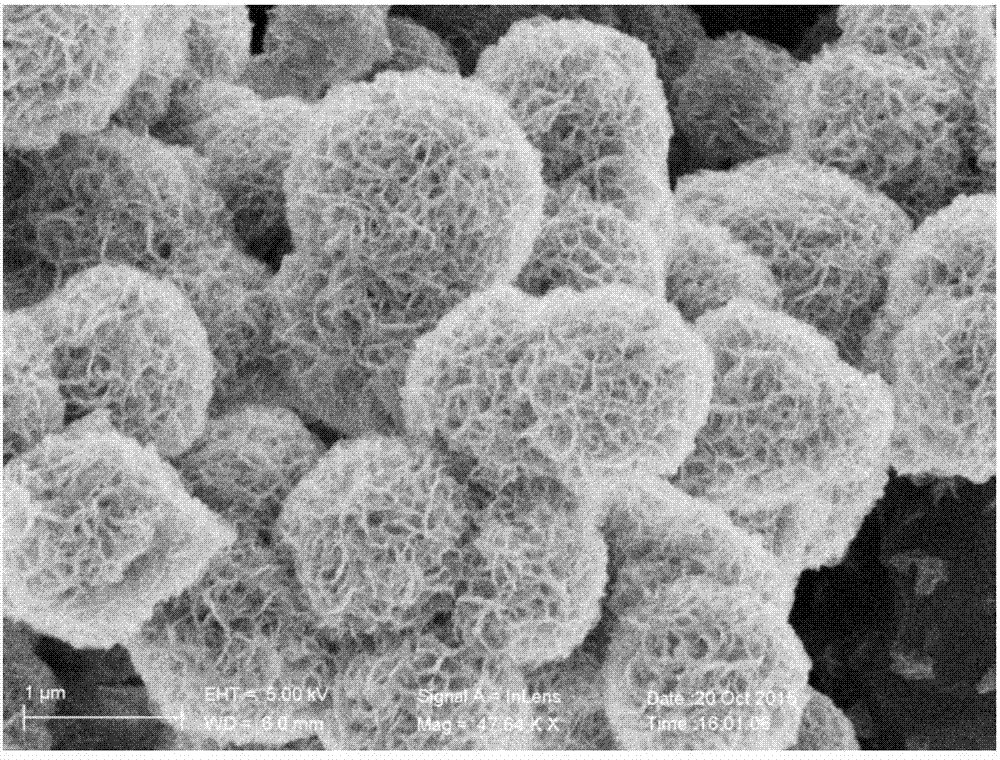

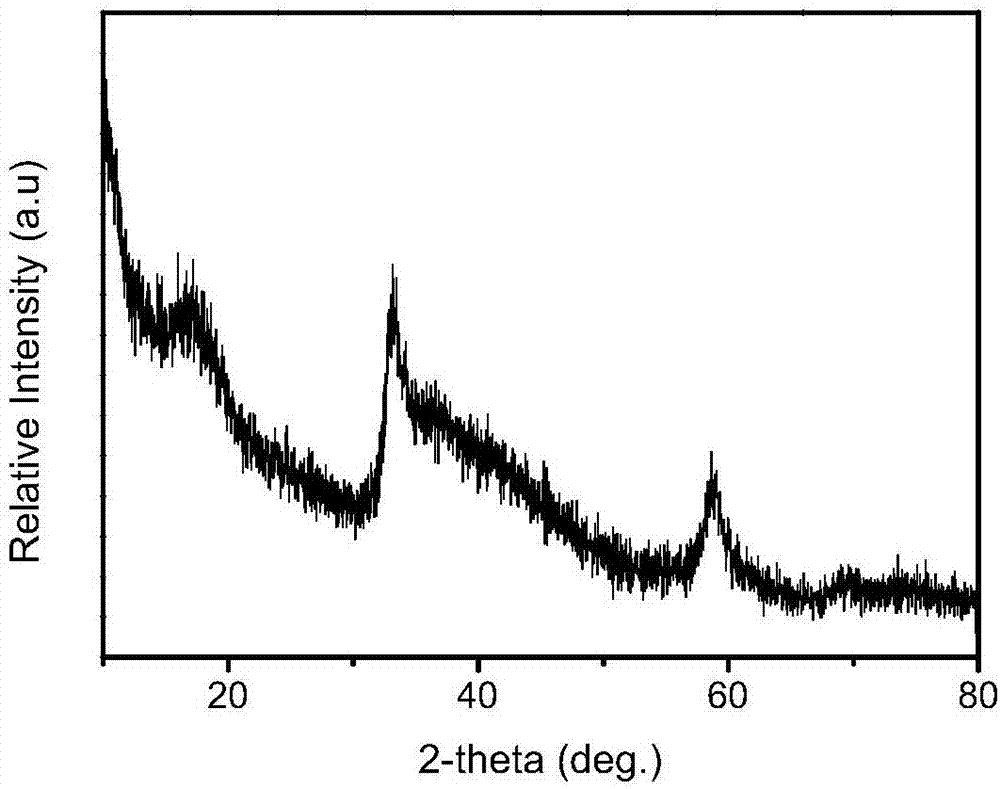

[0028] The preparation method of the molybdenum disulfide / carbon microsphere lithium ion battery negative electrode material in this embodiment is as follows: 0.1g polystyrene microspheres, 0.1g sodium molybdate dihydrate, 0.14g thiourea and 0.05g glucose are dissolved in 40mL of deionized water to obtain a mixed solution (wherein, the mass-volume concentration of polystyrene microspheres is 2.5 mg / mL, and the molar concentrations of sodium molybdate dihydrate, thiourea and glucose are respectively 10.33 mmol / L, 45.98 mmol / L and 6.95 mmol / L mmol / L), the mixed solution was placed in a 50 mL reaction kettle, reacted at 200° C. for 10 hours, naturally cooled to room temperature, and the solution after the reaction was centrifugally washed and dried to obtain black powder.

[0029] The obtained black powder was heated and sintered in a nitrogen atmosphere at a heating rate of 2°C / min, firstly heated to 200°C, held for 2 hours, then heated to 700°C, held for 2 hours to obtain lithiu...

Embodiment 2

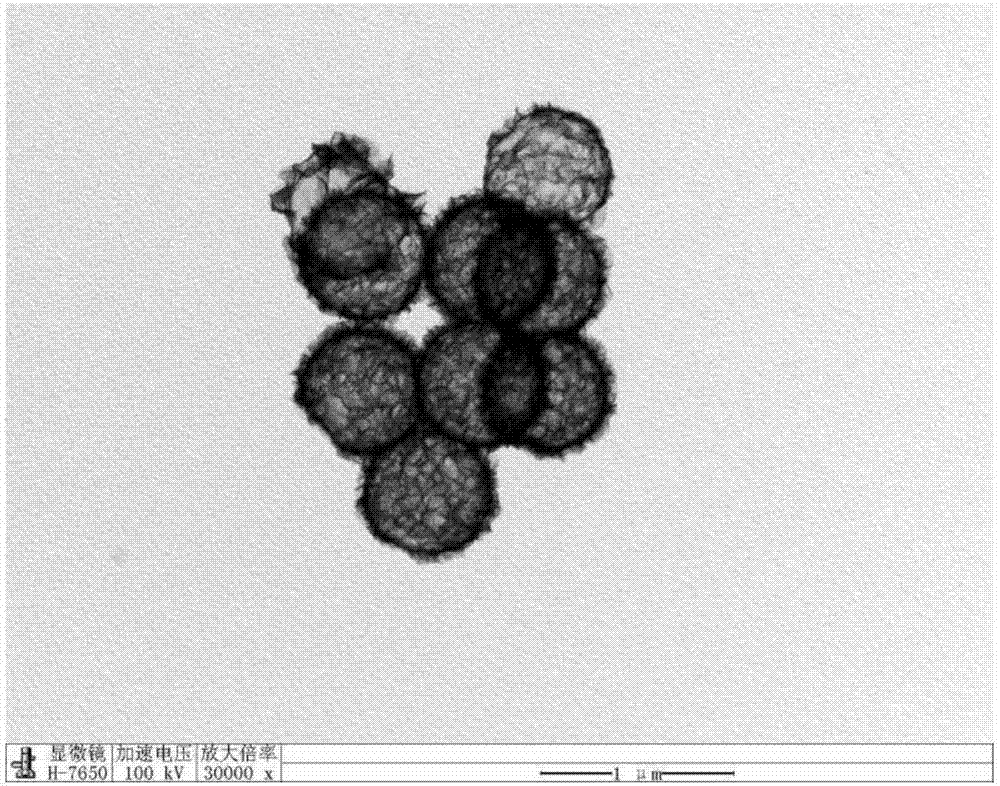

[0035] Dissolve 0.1 g of polystyrene microspheres (500 nm in diameter), 0.1 g of sodium molybdate dihydrate, 0.14 g of thiourea and 0.1 g of glucose in 40 mL of deionized water to obtain a mixed solution (wherein, the mass of polystyrene microspheres - Volume concentration is 2.5mg / mL, and the molar concentration of sodium molybdate dihydrate, thiourea and glucose is respectively 10.33mmol / L, 45.98mmol / L and 13.89mmol / L), mixed solution is inserted into 50mL reactor, at 200 The reaction was carried out at ℃ for 12 hours, then cooled to room temperature naturally, the solution after the reaction was washed by centrifugation, and dried to obtain a black powder.

[0036] The obtained black powder was heated and sintered under a nitrogen atmosphere at a heating rate of 2°C / min, firstly heated to 200°C, held for 2 hours, then heated to 800°C and held for 2 hours;

[0037] The molybdenum disulfide / carbon microsphere lithium ion battery anode material prepared in Example 2 was charac...

Embodiment 3

[0039] The difference between Example 3 and Example 2 is that the amount of polystyrene microspheres added is adjusted. Weigh 0.2 g of polystyrene microspheres and dissolve them in 40 mL of deionized water. Other steps are the same as in Example 2, and the prepared negative electrode material is 1Ag -1 The first discharge is easy to be 705.2 mAh / g, the first efficiency is 55.6%, and the discharge capacity after 500 cycles is 648.1 mAh / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com