Composite hydrogen evolution electro-catalysis material and preparation method

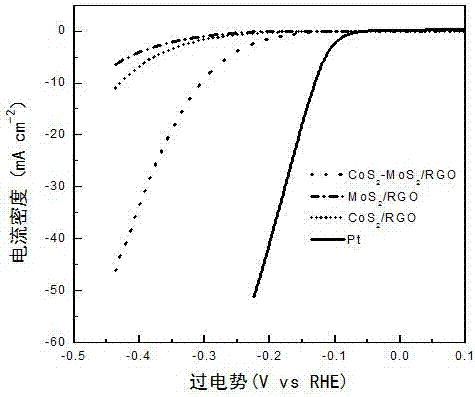

An electrocatalytic material and a catalytic material technology, which are applied in the field of molybdenum disulfide-cobalt disulfide/graphene composite hydrogen evolution electrocatalytic material and preparation, can solve the problems of difficult preparation of MoP, complicated preparation process, low RGO yield, etc. Abundant reserves, speeding up the transmission rate, overcoming the effects of poor stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

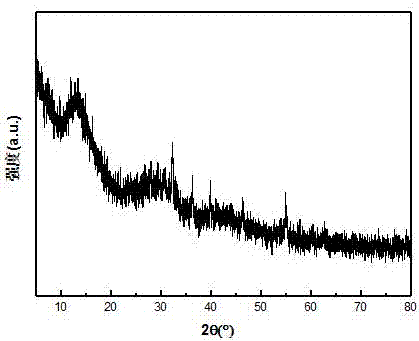

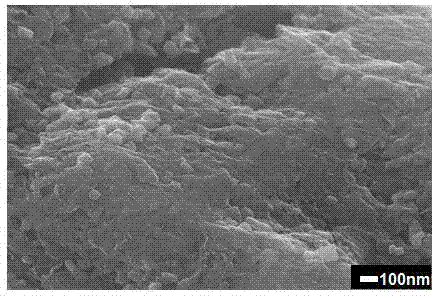

Embodiment 1

[0022] Utilize the improved Hummers method to prepare graphene oxide; Weigh 24.2mg sodium molybdate dihydrate, 29.1mg cobalt nitrate hexahydrate, 30.4mg thiourea, 30mg graphene oxide and 30ml deionized water in a beaker, stir and sonicate to Uniform mixed solution; transfer the above mixed solution to a 40ml polytetrafluoroethylene-lined reactor, place it in an oven at 200°C, and react at a constant temperature for 18 hours; after the reaction, take out the reactor and cool it to room temperature; The product is centrifuged and washed 4-5 times with deionized water and ethanol (centrifugal speed 6000rmp, centrifugation time 1min), which obtains molybdenum disulfide-cobalt disulfide / graphene composite; finally the composite is washed once with deionized water; Place the molybdenum disulfide-cobalt disulfide / graphene composite after washing and centrifugation in the refrigerator, freeze and pretreat at -10°C for 2h, then place the pretreated sample in a freeze dryer at -45°C for ...

Embodiment 2

[0026] Utilize the improved Hummers method to prepare graphene oxide; Weigh 39.6mg sodium molybdate dihydrate, 45.2mg cobalt nitrate hexahydrate, 47.0mg thiourea and 55mg graphene oxide and 30ml deionized water in a beaker, stir, sonicate to Uniform mixed solution; transfer the above mixed solution to a 40ml polytetrafluoroethylene-lined reactor, place it in an oven at 200°C, and react at a constant temperature for 18 hours; after the reaction, take out the reactor and cool it to room temperature; The product is centrifuged and washed 4-5 times with deionized water and ethanol (centrifugal speed 6000rmp, centrifugation time 1min), which obtains molybdenum disulfide-cobalt disulfide / graphene composite; finally the composite is washed once with deionized water; Place the molybdenum disulfide-cobalt disulfide / graphene composite after washing and centrifugation in the refrigerator, freeze and pretreat at -10°C for 2h, then place the pretreated sample in a freeze dryer at -45°C for ...

Embodiment 3

[0030] Utilize improved Hummers method to prepare graphene oxide; Weigh 48.0mg sodium molybdate dihydrate, 58.0mg cobalt nitrate hexahydrate, 76.0mg thiourea and 60mg graphene oxide and 30ml deionized water in a beaker, stir, ultrasonic to a uniformly mixed solution; transfer the above mixed solution to a 40ml polytetrafluoroethylene-lined reactor, place it in an oven at 200°C, and react at a constant temperature for 18 hours; after the reaction, take out the reactor and cool it to room temperature; The product in the product is centrifuged and washed 4-5 times with deionized water and ethanol (centrifugal speed 6000rmp, centrifugation time 1min) to obtain molybdenum disulfide-cobalt disulfide / graphene composite; finally the composite is washed once with deionized water ; Place the molybdenum disulfide-cobalt disulfide / graphene composite after washing and centrifugation in a refrigerator, freeze and pretreat at -10°C for 2h, then place the pretreated sample in a freeze dryer at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com