Automatic production process of concrete precast products

A technology for prefabricated products and production processes, applied in manufacturing tools, ceramic molding workshops, ceramic molding machines, etc., can solve the problems of low early strength of concrete, slump deviation, sacrificing quality, etc., to solve mixing quality problems, improve Strength, the effect of solving the problem of tortoise cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0023] In this embodiment, the automatic production process of the subway segment is taken as an example to further describe the present invention in detail and completely. However, the process method involved in the present invention is equally applicable to concrete products of other shapes, specifications and uses in the field.

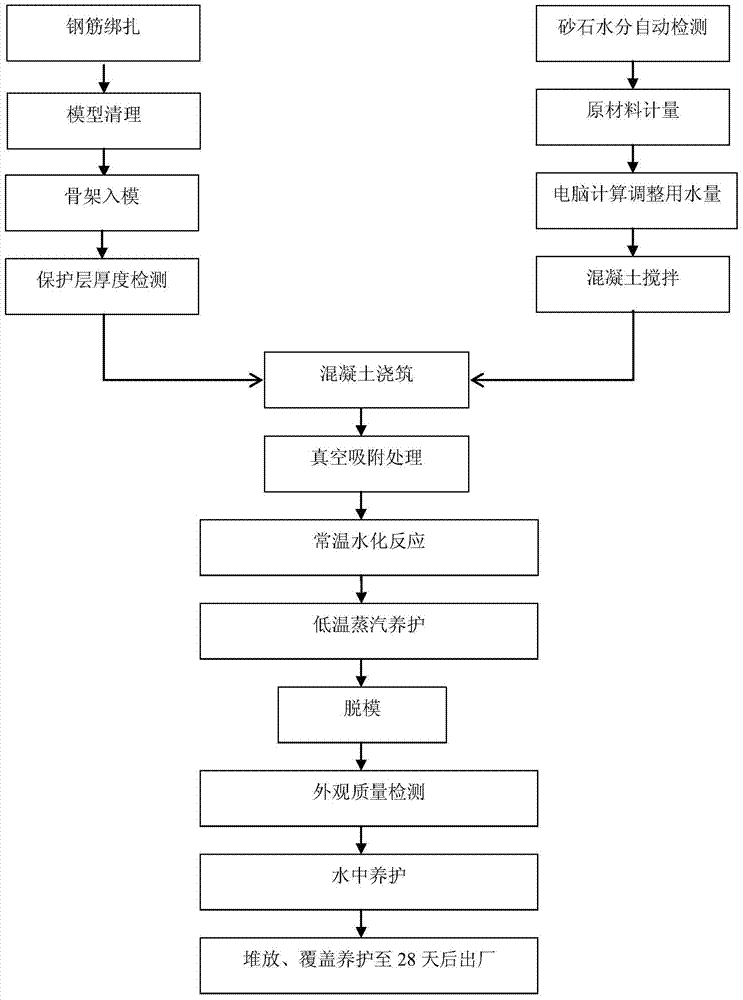

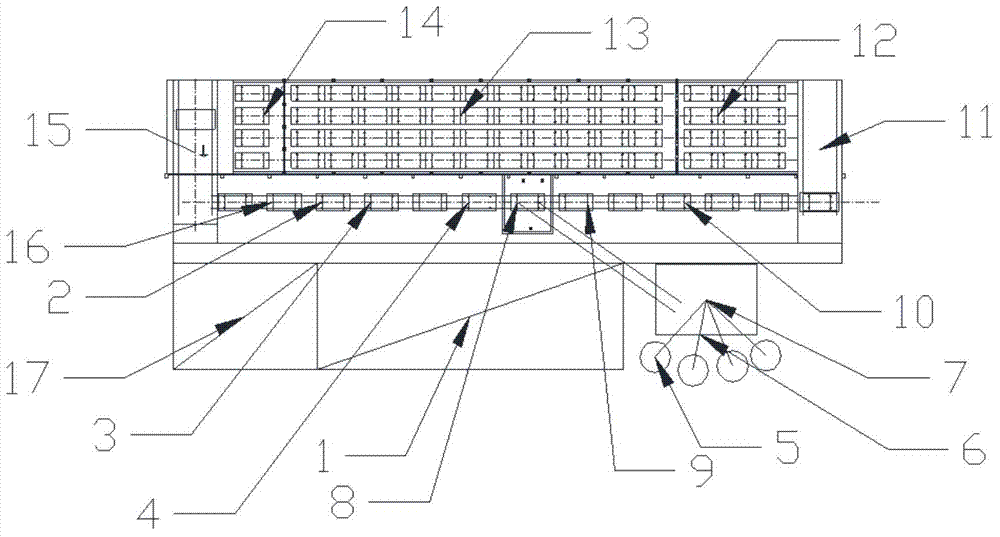

[0024] Such as figure 1 and figure 2 As shown, the automated production process of subway segments includes the following procedures in turn:

[0025] Step 1. Binding of steel bars: in the steel bar processing area (1), tie the steel bar skeleton of the segment on the fixed model to form a steel bar cage;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com