Protective agent for bridge with steel structure, preparation method thereof and application thereof

A protective agent, a technology for steel structure bridges, applied in the direction of anti-corrosion coatings, coatings, etc., can solve the problem of difficult to guarantee the corrosion damage of steel structure bridges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

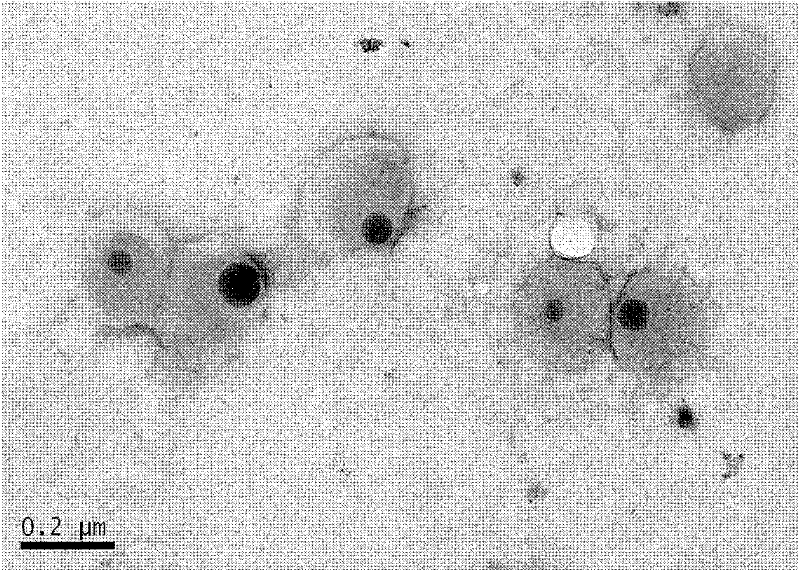

Image

Examples

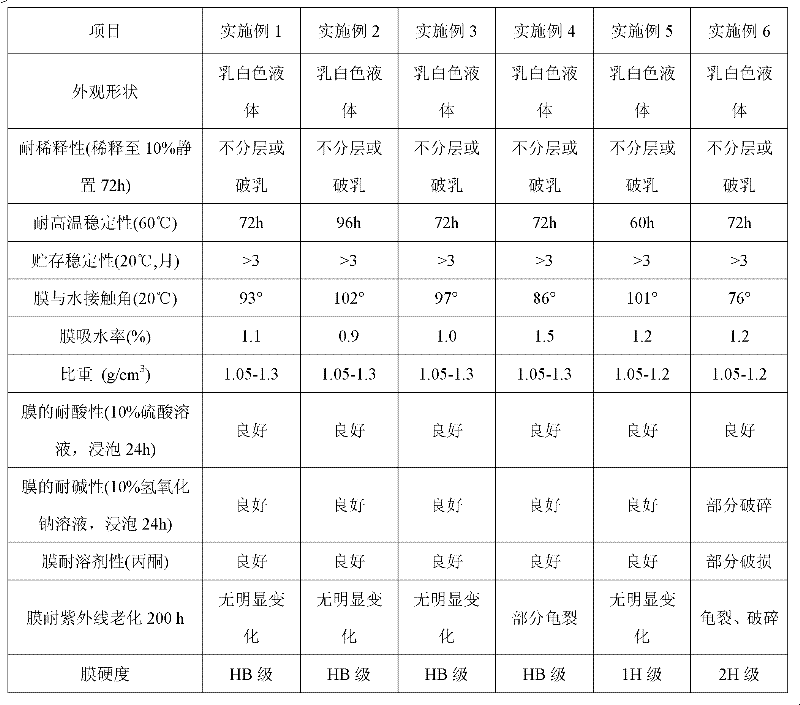

Embodiment 1

[0096] Mix 0.1 kg of aluminum isopropoxide, 0.3 kg of butyl titanate, 1.7 kg of tetraethyl silicate, and 6 kg of absolute ethanol for use; mix 10 kg of absolute ethanol, 0.4 kg of distilled water, and 0.1 kg of ammonia water ( The mass fraction is 25%) into a reactor equipped with a reflux condensing device and an electric stirrer, stirred at a speed of 150 rpm for 1-2 hours, mixed uniformly and then slowly heated up; when the temperature rose to 45-60°C, Add the organic alkoxide and ethanol mixture dropwise into the reactor, stir rapidly at a speed of 200 rpm, and react for 2-4 hours; stir and age at room temperature for 24 hours to obtain the desired alcohol sol of the inorganic nanomaterial. Under the condition of low-speed stirring, add 0.18 kg of methacryloxypropyltrimethoxysilane dropwise into the alcohol sol of inorganic nanomaterials, react at room temperature for 22 hours, raise the temperature to 50°C and react at constant temperature for 2 hours, and the surface modi...

Embodiment 2

[0100] The organic / inorganic composite fluorosilicone styrene-acrylic polymer emulsion was prepared as in Example 1.

[0101] Add 80 kg of organic / inorganic composite fluorosilicone styrene-acrylic polymer emulsion and 20 kg of distilled water into a mixer with a stirrer, and mix evenly at a speed of 100 rpm; heat up to 40±5°C, and lithium silicate 0.8 kg, 0.1 kg of sodium molybdate, 0.7 kg of benzotriazole and 1 kg of absolute ethanol, 0.6 kg of sodium gluconate, 0.04 nanometer titanium dioxide, 5 kg of ethanolamine and 0.06 kg of sodium tetraborate are slowly added to the mixer in turn and stir for 2-6 hours to obtain the protective agent for steel structure bridges.

Embodiment 3

[0103] The organic / inorganic composite fluorosilicone styrene-acrylic polymer emulsion was prepared as in Example 1.

[0104] Add 70 kg of organic / inorganic composite fluorosilicone styrene-acrylic polymer emulsion and 30 kg of water into a mixer with a stirrer, and mix evenly at a speed of 100 rpm; heat up to 40±5°C, and lithium silicate 0.8 kg, 0.12 kg of sodium molybdate, 0.6 kg of benzotriazole and 1 kg of absolute ethanol, 0.5 kg of sodium gluconate, 0.05 kg of nano-titanium dioxide, 3 kg of ethanolamine and 0.06 kg of sodium tetraborate are slowly added to the mixer in turn and stir for 2-6 hours to obtain the protective agent for steel structure bridges.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com