Washing-free normal-temperature phosphating solution after steel workpiece phosphating and preparation method thereof

A technology of water-free washing and phosphating solution, applied in the coating process of metal materials, etc., can solve the problems of high phosphating temperature, complex process, and many harmful waste water, achieve good adhesion, overcome complex process, and reduce residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

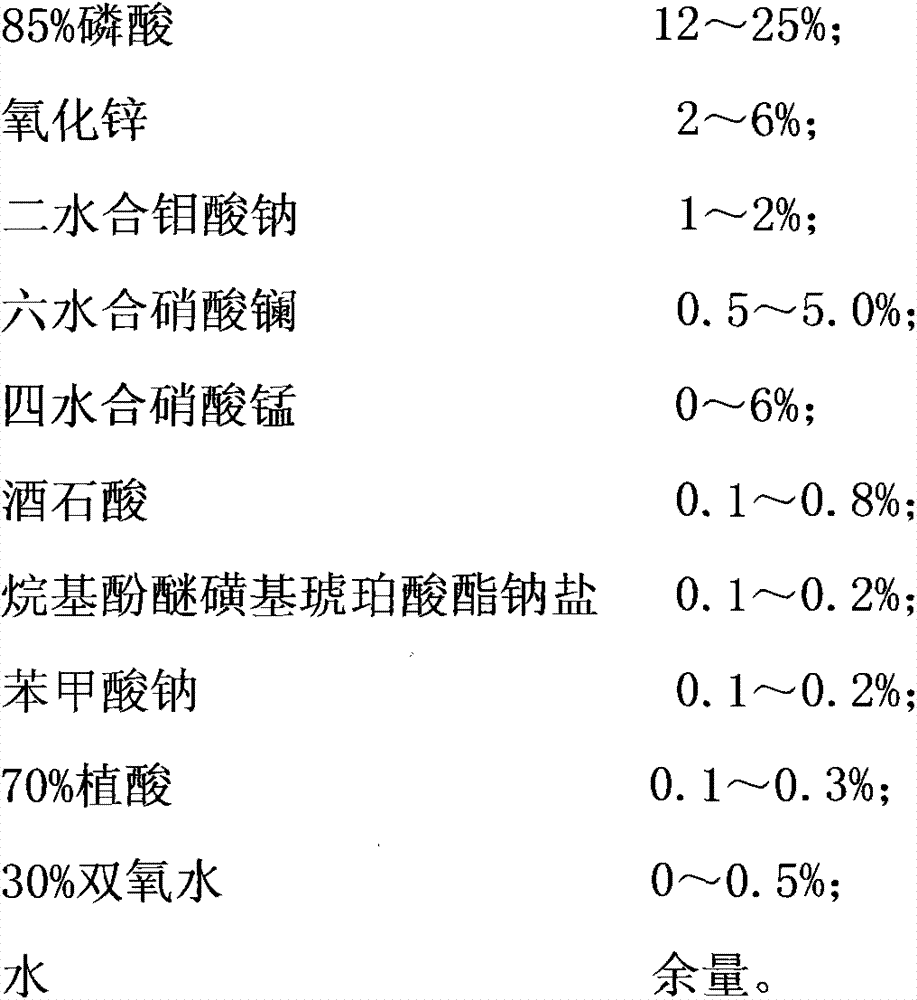

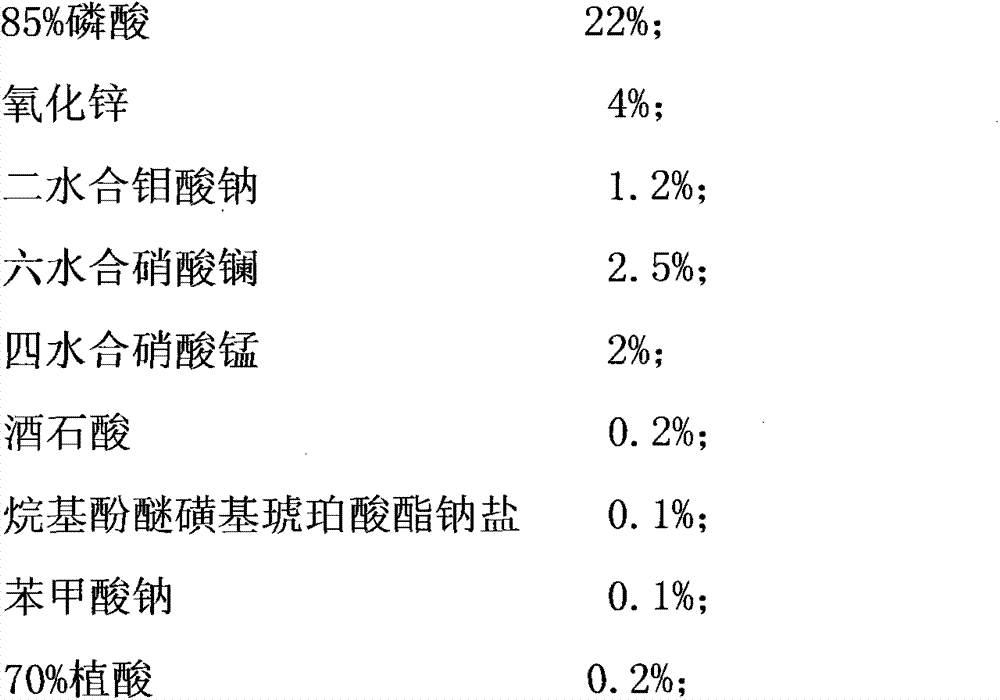

[0022] The phosphating solution is composed of the following raw materials and mass percentage:

[0023] 85% phosphoric acid 22%, zinc oxide 4%, sodium molybdate dihydrate 1.2%, lanthanum nitrate hexahydrate 2.5%, manganese nitrate tetrahydrate 2%, tartaric acid 0.2%, alkylphenol ether sulfosuccinate sodium salt 0.1% , sodium benzoate 0.1%, 70% phytic acid 0.2%, 30% hydrogen peroxide 0.2%, water balance.

[0024] Preparation method: first add zinc oxide to water twice the mass of zinc oxide and stir to make a paste, add 85% phosphoric acid, stir until uniform and transparent, and then add and stir successively; ①phytic acid and tartaric acid dissolved in water, ②respectively Lanthanum nitrate hexahydrate and manganese nitrate tetrahydrate that have been dissolved in water, ③ sodium molybdate dihydrate that has been dissolved in water; ④ the remaining raw materials except sodium benzoate, ⑤ sodium benzoate that has been dissolved in hot water; ⑥ ammonia water Adjust the pH val...

Embodiment 2

[0026] The phosphating solution is composed of the following raw materials and mass percentage:

[0027] 85% phosphoric acid 22%, zinc oxide 2.5%, sodium molybdate dihydrate 1.5%, lanthanum nitrate hexahydrate 2%, manganese nitrate tetrahydrate 3%, tartaric acid 0.3%, alkylphenol ether sulfosuccinate sodium salt 0.1% , 0.1% sodium benzoate, 0.3% 70% phytic acid, 0.2% 30% hydrogen peroxide, and the balance of water.

[0028] Preparation method: with embodiment 1.

Embodiment 3

[0030] The phosphating solution is composed of the following raw materials and mass percentage:

[0031] 85% Phosphoric Acid 23%, Zinc Oxide 3%, Sodium Molybdate Dihydrate 1.1%, Lanthanum Nitrate Hexahydrate 4.5%, Tartaric Acid 0.2%, Alkylphenol Ether Sulfosuccinate Sodium Salt 0.2%, Sodium Benzoate 0.1%, 70 % Phytic acid 0.1%, 30% hydrogen peroxide 0.2%, the balance of water.

[0032] Preparation method: with embodiment 1.

[0033] Using this formula for phosphating can shorten the phosphating time, and the phosphating film after phosphating completely meets or exceeds the performance parameters of the phosphating film after phosphating in the prior art. The performance comparison of the phosphating film is shown in Table 1.

[0034] Table 1 Performance comparison of phosphating film

[0035]

[0036] *The data in this row are the mean values of the three examples.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com