Preparation method of NiMo hydrogen evolution electrocatalyst

An electrocatalyst and hydrogen evolution technology, which is applied in the field of electrocatalysis hydrogen evolution, can solve the problems of high equipment requirements and large environmental impact, and achieve the effect of reducing costs and good catalytic hydrogen evolution activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

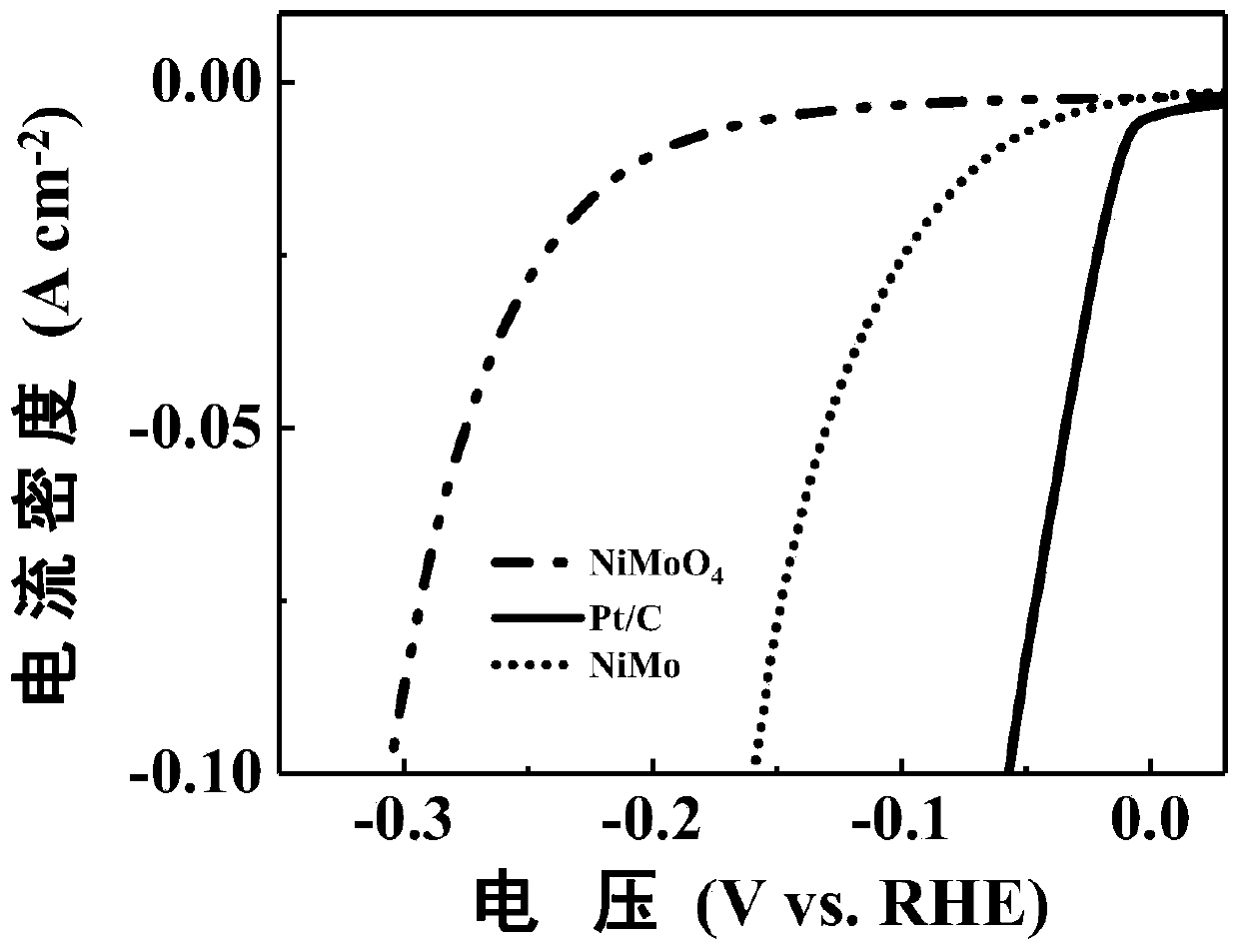

[0024] A kind of preparation method of NiMo hydrogen evolution electrocatalyst of the present embodiment, comprises the following steps:

[0025] (1) 290.8mg nickel nitrate hexahydrate and 241.9mg sodium molybdate dihydrate are added to 40ml deionized water respectively, and the two are completely dissolved by stirring. The molar concentration is 25mmol / L, and the mass concentrations of nickel nitrate hexahydrate and sodium molybdate dihydrate in the deionized water are 7.27mg / ml and 6.05mg / ml respectively;

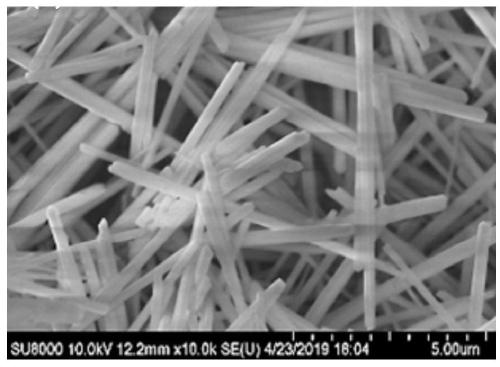

[0026] (2) Transfer the solution prepared in step (1) to the reaction kettle, add nickel foam, and conduct a hydrothermal reaction at 160° C. for 5 hours to obtain a nickel molybdate precursor material;

[0027] (3) The sample prepared in step (2) is placed in a tube furnace, and heat-treated under a nitrogen atmosphere, the heat-treatment temperature is 350° C., and the heat-treatment time is 1 hour to obtain nickel molybdate;

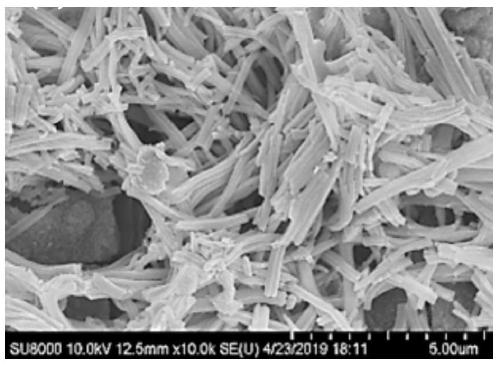

[0028] (4) The sample prepared in step (3...

Embodiment 2

[0035] A kind of preparation method of NiMo hydrogen evolution electrocatalyst of the present embodiment, comprises the following steps:

[0036] (1) 320mg nickel nitrate hexahydrate and 266.4mg sodium molybdate dihydrate are added to 40ml deionized water respectively, and the two are completely dissolved by stirring. The concentrations are all 27.5mmol / L, and the mass concentrations of nickel nitrate hexahydrate and sodium molybdate dihydrate in the deionized water are 8.0mg / ml and 6.66mg / ml respectively;

[0037] (2) Transfer the solution prepared in step (1) to the reaction kettle, add nickel foam, and conduct a hydrothermal reaction at 160° C. for 6 hours to obtain a nickel molybdate precursor material;

[0038] (3) the sample prepared by step (2) is placed in a tube furnace, and heat-treated under a nitrogen atmosphere, the heat-treatment temperature is room temperature, and the heat-treatment time is 2 hours to obtain nickel molybdate;

[0039] (4) The sample prepared i...

Embodiment 3

[0042] A kind of preparation method of NiMo hydrogen evolution electrocatalyst of the present embodiment, comprises the following steps:

[0043] (1) 280mg nickel nitrate hexahydrate and 233.2mg sodium molybdate dihydrate are added to 40ml deionized water respectively, stir to make the two dissolve completely, the molar amount of nickel nitrate hexahydrate and sodium molybdate dihydrate in the deionized water The concentrations are all 24.1mmol / L, and the mass concentrations of nickel nitrate hexahydrate and sodium molybdate dihydrate in the deionized water are 7.0mg / ml and 5.83mg / ml respectively;

[0044] (2) Transfer the solution prepared in step (1) to the reaction kettle, add nickel foam, and conduct a hydrothermal reaction at 160° C. for 5.5 hours to obtain a nickel molybdate precursor material;

[0045] (3) The sample prepared in step (2) is placed in a tube furnace, and heat-treated under a nitrogen atmosphere, the heat-treatment temperature is 200° C., and the heat-tre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com