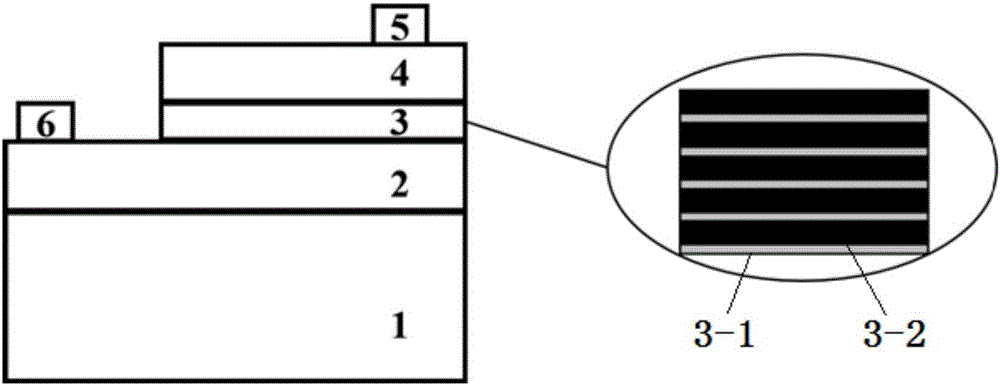

Light-emitting diode and laser of p-GaN/ZnO-based multi-quantum well/n-ZnO structure and preparation method

A light-emitting diode, p-gan technology, applied in lasers, phonon exciters, laser parts and other directions, to achieve the effect of improving emission efficiency, stable and reliable p-type conductivity, and high crystal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1) Substrate cleaning: Put the sapphire substrate with the p-GaN layer into acetone, alcohol and deionized water in order to ultrasonically clean it for 10 min, rinse with deionized water, and blow dry with nitrogen.

[0033] 2) Substrate pretreatment: put the above-mentioned cleaned substrate into the molecular beam epitaxy system pretreatment chamber and bake for 3 hours at a temperature of 300°C; then put it into a high-vacuum growth chamber for high temperature treatment at 800°C for 30 minutes.

[0034] 3) Deposit 5 cycles of ZnO / ZnMgO multiquantum wells on the p-GaN layer by molecular beam epitaxy, and reserve the area for growing the first electrode at the same time, using pure metal Zn (purity 99.9998%) as the Zn source, pure metal Mg (99.9999% pure) as the source of Mg, pure O activated by RF 2 (purity is 99.9999%) is the O source, the substrate temperature is 650 ° C, the Zn source furnace temperature is 250 ° C, the Mg source furnace temperature is 350 ° C, t...

Embodiment 2

[0038] 1) Substrate cleaning: Put the sapphire substrate with the p-GaN layer into acetone, alcohol and deionized water in order to ultrasonically clean it for 10 min, rinse with deionized water, and blow dry with nitrogen.

[0039] 2) Substrate pretreatment: put the above-mentioned cleaned substrate into the molecular beam epitaxy system pretreatment chamber and bake for 3 hours at a temperature of 300°C; then put it into a high-vacuum growth chamber for high temperature treatment at 800°C for 30 minutes.

[0040] 3) Deposit 5 cycles of ZnO / ZnMgO multiquantum wells on the p-GaN layer by molecular beam epitaxy, and reserve the area for growing the first electrode at the same time, using pure metal Zn (purity 99.9998%) as the Zn source, pure metal Mg (99.9999% pure) as the source of Mg, pure O activated by RF 2 (purity is 99.9999%) is the O source, the substrate temperature is 700°C, the Zn source furnace temperature is 250°C, the Mg source furnace temperature is 355°C, the oxy...

Embodiment 3

[0044] 1) Substrate cleaning: Put the sapphire substrate with the p-GaN layer into acetone, alcohol and deionized water in order to ultrasonically clean it for 10 min, rinse with deionized water, and blow dry with nitrogen.

[0045] 2) Substrate pretreatment: put the above-mentioned cleaned substrate into the molecular beam epitaxy system pretreatment chamber and bake for 3 hours at a temperature of 300°C; then put it into a high-vacuum growth chamber for high temperature treatment at 800°C for 30 minutes.

[0046] 3) Using molecular beam epitaxy to deposit 8 cycles of ZnO / ZnMgO multiquantum wells on the p-GaN layer, while reserving the area for growing the first electrode, using pure metal Zn (purity 99.9998%) as the Zn source, pure metal Mg (99.9999% pure) as the source of Mg, pure O activated by RF 2 (purity is 99.9999%) is the O source, the substrate temperature is 700 ° C, the Zn source furnace temperature is 250 ° C, the Mg source furnace temperature is 360 ° C, the oxyg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com