Bidentate ligand and its iridium complex and electroluminescent device therewith

A technology of bidentate ligands and iridium complexes, which is applied in the field of heavy metal element iridium complex light-emitting materials, can solve the problems of high cost and complicated preparation process, and achieve improved brightness and efficiency, excellent electrophosphorescence performance, and good current carrying Effect of Subtransfer Performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below through specific examples, but these specific embodiments do not limit the protection scope of the present invention in any way.

[0027] The raw materials used in this embodiment are known compounds, which can be purchased in the market, or can be synthesized by methods known in the art.

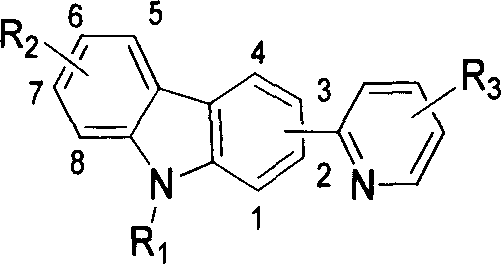

[0028] 1: Ligand N-decyl-2-pyridylcarbazole (2-PyC), N-decyl-3-pyridylcarbazole (3-PyC) and N-ethyl-3-pyridylcarbazole Synthesis of azole (3-PyCE)

[0029] 2-Bromopyridine (0.47ml, 4.7mmol) was dissolved in 7.5ml of dry THF in a Schlenk tube, kept at -78°C, and n-butyllithium (2.5M in hexane, 4.0ml) was added dropwise over 15 minutes , 9.4mmol), after stirring for 45 minutes, anhydrous zinc chloride solution (1.28g, 9.4mmol dissolved in 15ml THF) was added, and gradually rose to room temperature within 15 minutes, and continued to stir for 1.5h. Then, add 2-bromo-N-n-decylcarbazole or 3-bromo-N-n-decylcarbazole (1.79g, 4.6mmol) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum external quantum efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com