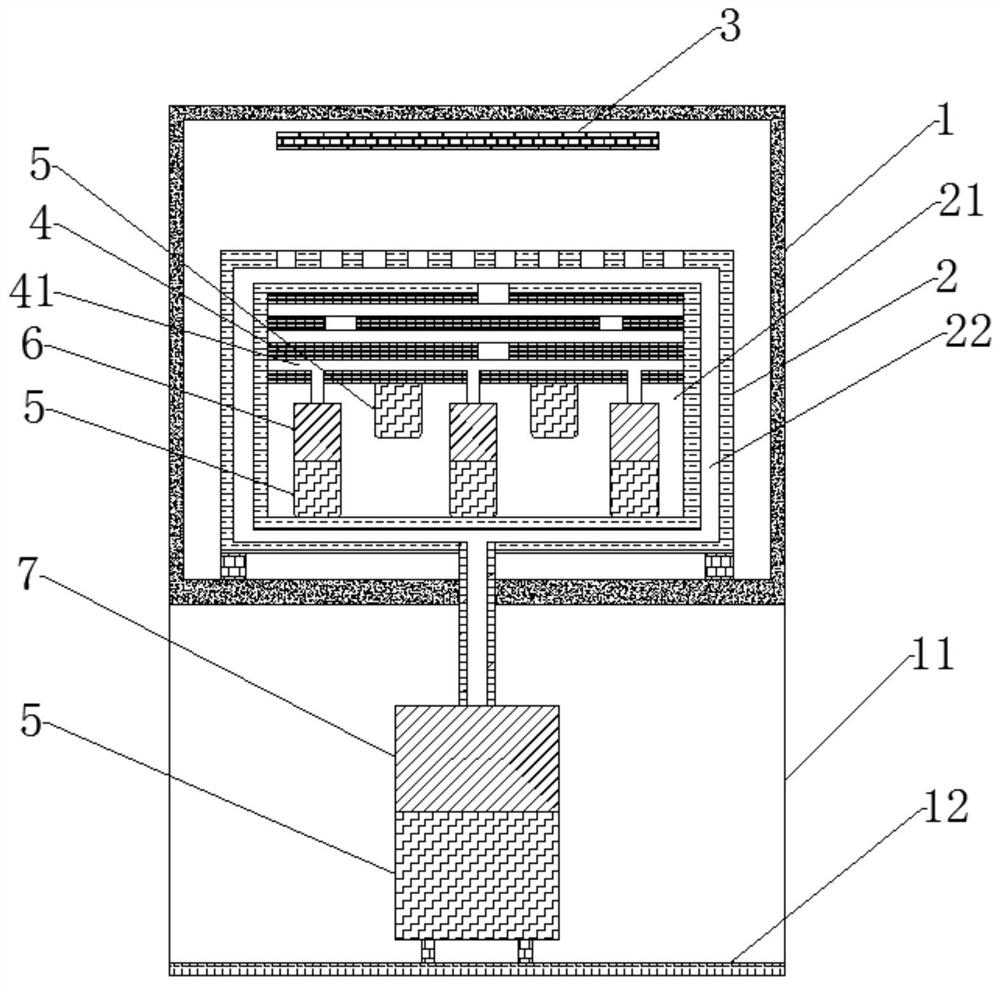

A large-size substrate evaporation device and a method for preparing CDTE solar coatings using the evaporation device

A large-scale, evaporation technology, applied in vacuum evaporation plating, sputtering plating, ion implantation plating, etc., can solve the problems of high maintenance cost, low controllability, and large environmental impact, and achieve large-scale The effect of production and improvement of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

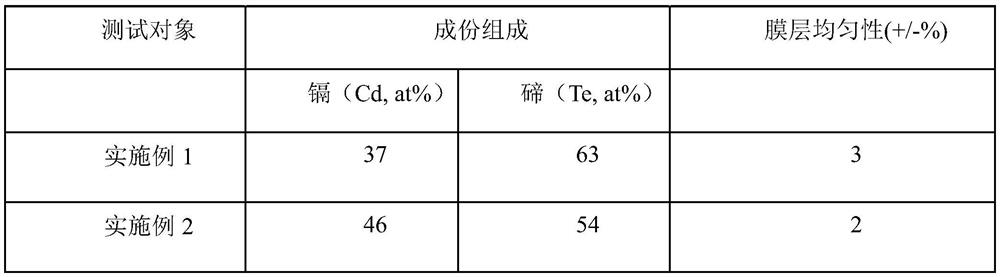

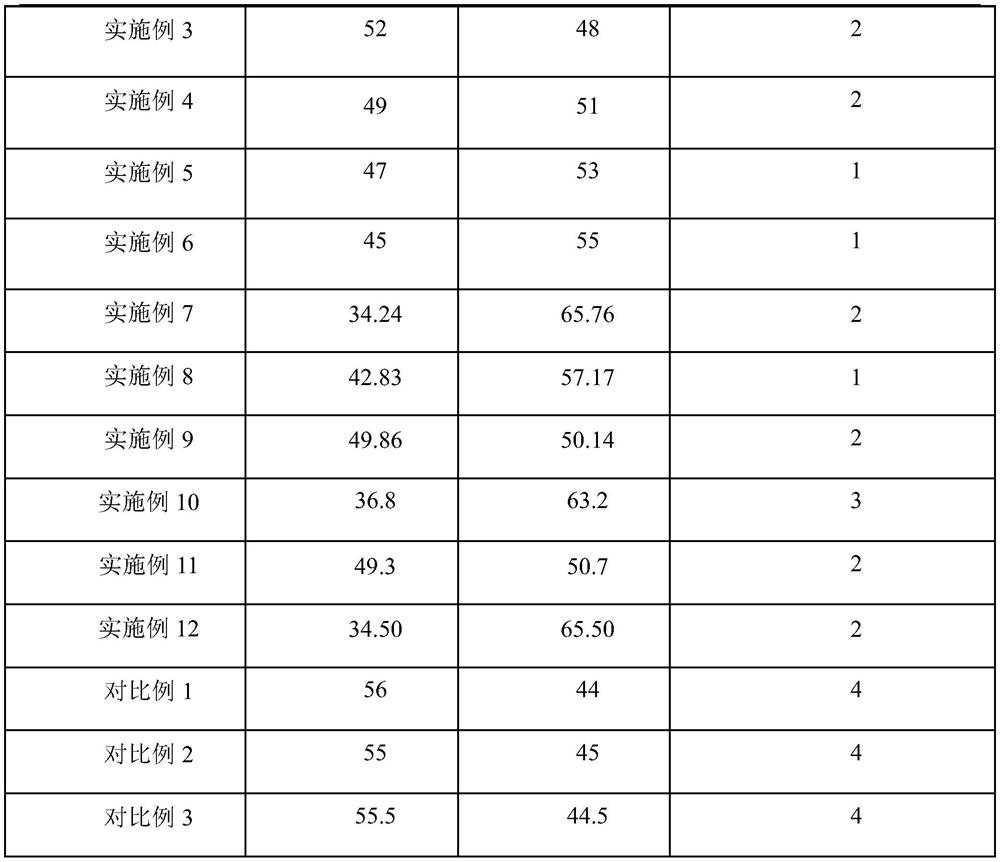

Embodiment 1

[0035] The method for preparing a CdTe solar coating film based on the large-scale substrate evaporation device proposed by the present invention comprises the following steps:

[0036] S1. Put cadmium element and tellurium element with a purity greater than 99.99% into the upper crucible 6 and the lower crucible 7 respectively, wherein the upper crucible is a tantalum crucible, and the lower crucible is a stainless steel crucible;

[0037] S2. Place the vapor deposition box 1 in the vapor deposition chamber of the vapor deposition machine, and use a vacuum pumping system to pump the background pressure of the vapor deposition chamber to 5×10 -6 torr;

[0038] S3. First heat the temperature in the sandwich box body 4 to 830°C, then heat the cadmium element in the upper crucible 6 to 530°C, and heat the tellurium element in the lower crucible 7 to 730°C, so that the cadmium element and tellurium element The forms of steam are gathered on the flexible stainless steel substrate ...

Embodiment 2

[0040] The method for preparing a CdTe solar coating film based on the large-scale substrate evaporation device proposed by the present invention comprises the following steps:

[0041] S1. Put cadmium element and tellurium element with a purity greater than 99.99% into the upper crucible 6 and the lower crucible 7 respectively, wherein the upper crucible is a tantalum crucible, and the lower crucible is a stainless steel crucible;

[0042] S2. Place the vapor deposition box 1 in the vapor deposition chamber of the vapor deposition machine, and use a vacuum pumping system to pump the background pressure of the vapor deposition chamber to 5×10 -6 torr;

[0043] S3. First heat the temperature in the sandwich box body 4 to 830°C, then heat the cadmium element in the upper crucible 6 to 610°C, and heat the tellurium element in the lower crucible 7 to 730°C, so that the cadmium element and tellurium element The forms of steam are gathered on the flexible stainless steel substrate ...

Embodiment 3

[0045] The method for preparing a CdTe solar coating film based on the large-scale substrate evaporation device proposed by the present invention comprises the following steps:

[0046] S1. Put cadmium element and tellurium element with a purity greater than 99.99% into the upper crucible 6 and the lower crucible 7 respectively, wherein the upper crucible is a tantalum crucible, and the lower crucible is a stainless steel crucible;

[0047] S2. Place the vapor deposition box 1 in the vapor deposition chamber of the vapor deposition machine, and use a vacuum pumping system to pump the background pressure of the vapor deposition chamber to 5×10 -6 torr;

[0048] S3. First heat the temperature in the sandwich box body 4 to 830°C, then heat the cadmium element in the upper crucible 6 to 780°C, and heat the tellurium element in the lower crucible 7 to 730°C, so that the cadmium element and tellurium element The forms of steam are gathered on the flexible stainless steel substrate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com