Preparation method of lithium-sulfur battery sandwich layer material

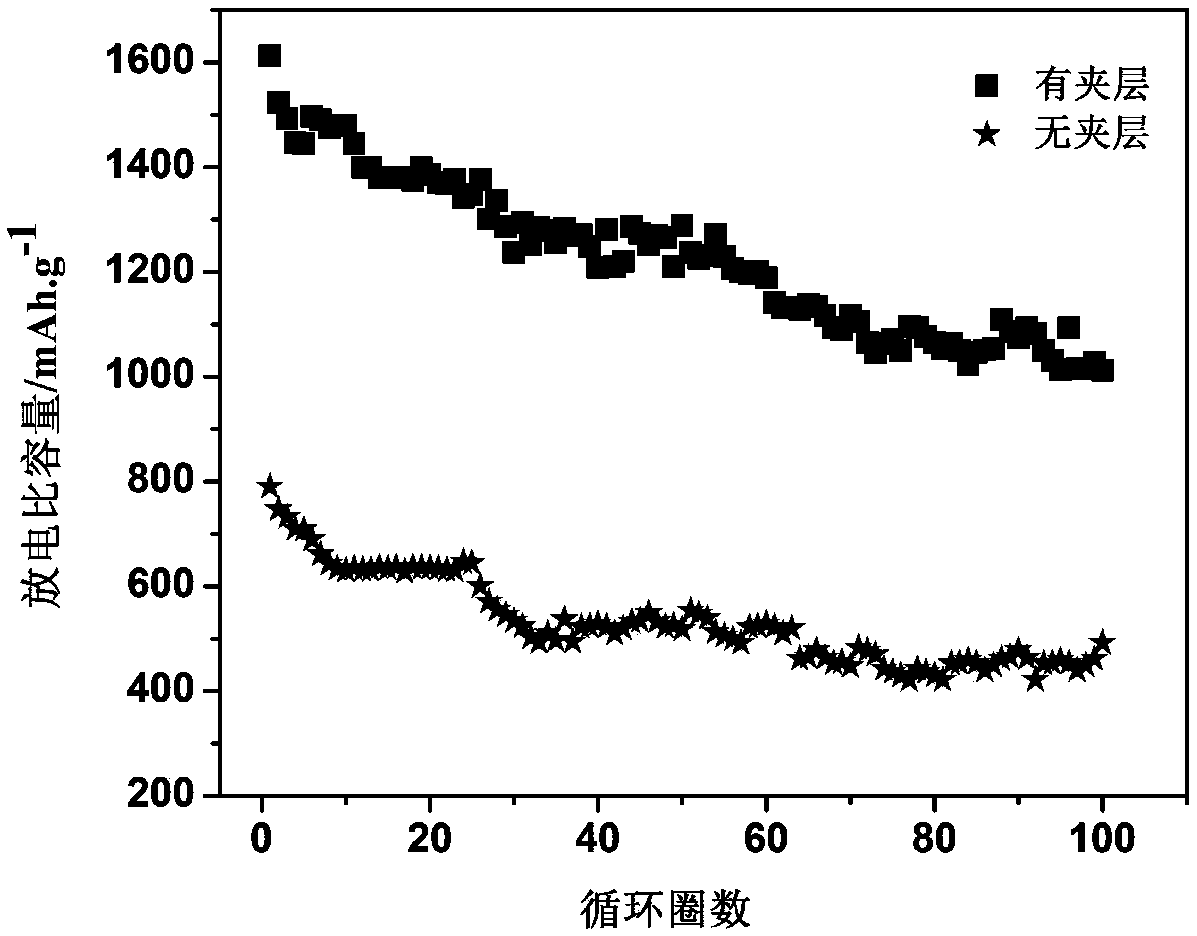

An interlayer material, lithium-sulfur battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of significant volume expansion effect of lithium-sulfur batteries, unstable battery electrochemical performance, etc., to achieve excellent electrochemical performance, experimental Simple and easy operation, the effect of improving cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

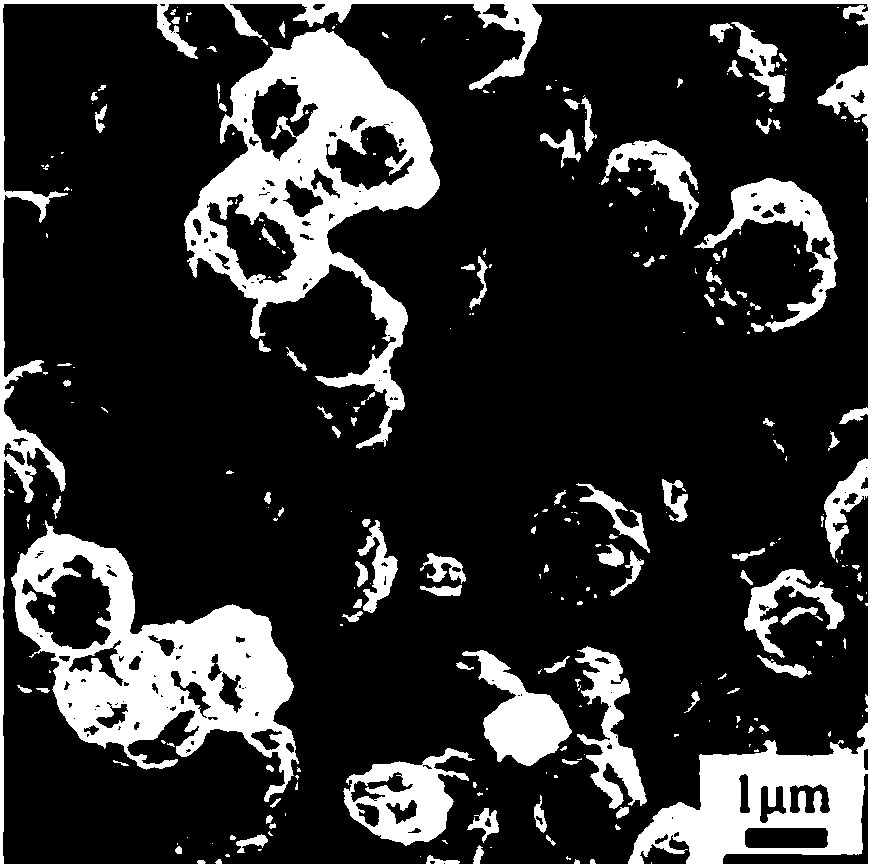

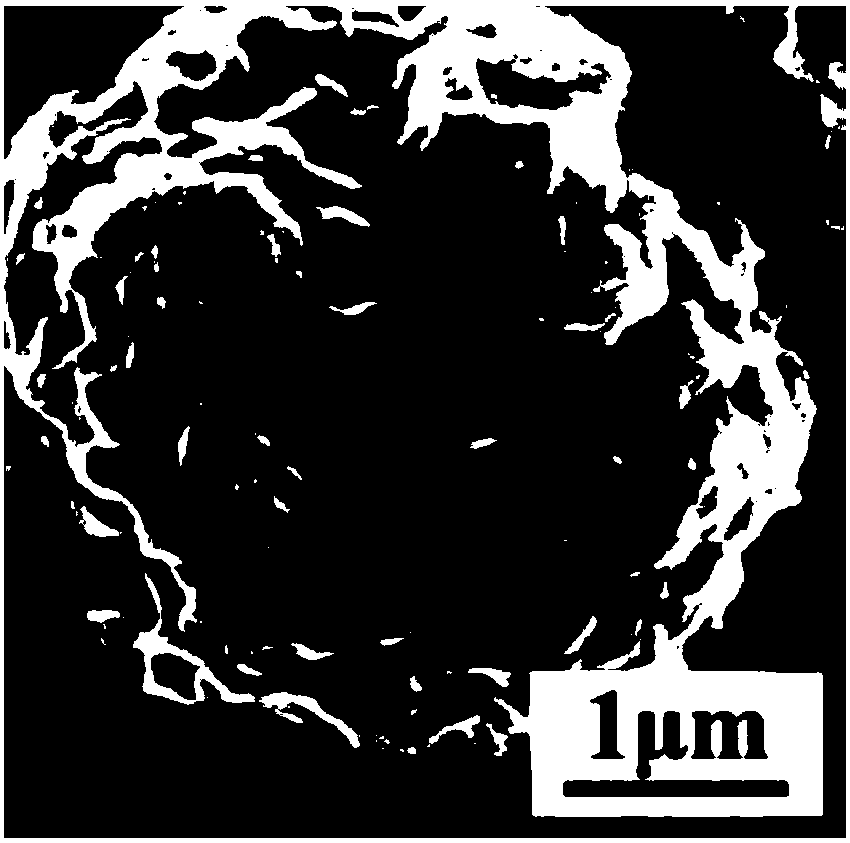

[0028] 0.01mol (2.42g) sodium molybdate dihydrate (Na 2 MoO 4 2H 2 O) with 0.03mol (2.28g) thiourea (H 2 NSCNH 2 ) and dissolved in 50ml of deionized water to prepare a mixed solution, stirred the mixed solution with electromagnetic stirring for 30min, then added hydrochloric acid (HCl) (12mol / L) dropwise, and adjusted the pH value of the mixed solution to 0.5 to obtain solution A. 0.01mol (1.70g) copper chloride dihydrate (CuCl 2 2H 2 O) and thiourea 0.04mol (3.04g) (H2NSCNH2) and dissolved in 50ml deionized water, electromagnetically stirred until completely dissolved to obtain solution B, mixed 5mlA solution with 5mlB solution to obtain solution C, 10mlC solution was added to 30mlGO solution, obtain D solution, transfer 40ml of the mixed solution D to a reaction kettle with polytetrafluoroethylene as the substrate, place the reaction kettle in an oven, keep it warm at 180°C for 2h, and then cool the reaction kettle naturally with the oven to room temperature, subseque...

Embodiment 2

[0030] 0.01mol (2.42g) sodium molybdate dihydrate (Na 2 MoO 4 2H 2 O) with 0.05mol (3.8g) thiourea (H 2 NSCNH 2 ) and dissolved in 50ml of deionized water to prepare a mixed solution, stirred the mixed solution with electromagnetic stirring for 30min, then added hydrochloric acid (HCl) (12mol / L) dropwise, and adjusted the pH value of the mixed solution to 0.5 to obtain solution A. 0.01mol (1.70g) copper chloride dihydrate (CuCl 2 2H 2 O) and thiourea 0.05mol (3.8g) (H 2 NSCNH 2 ) and dissolved in 50ml deionized water, stirred until completely dissolved to obtain solution B, mixed 5mlA solution with 5mlB solution to obtain solution C, added 10mlC solution to 40mlGO solution to obtain D solution, and transferred the mixed solution 50mlD to In a reaction kettle with polytetrafluoroethylene as the substrate, put the reaction kettle in an oven and keep it warm at 190 ° C for 8 hours, then cool the reaction kettle to room temperature naturally with the oven, and then obtain a...

Embodiment 3

[0032] 0.01mol (2.42g) sodium molybdate dihydrate (Na 2 MoO 4 2H 2 O) with 0.06mol (4.56g) thiourea (H 2 NSCNH 2 ) and dissolved in 50ml of deionized water to prepare a mixed solution, stirred the mixed solution with electromagnetic stirring for 30min, then added hydrochloric acid (HCl) (12mol / L) dropwise, and adjusted the pH value of the mixed solution to 0.5 to obtain solution A. 0.01mol (1.70g) copper chloride dihydrate (CuCl 2 2H 2 O) and thiourea 0.08mol (6.12g) (H 2 NSCNH 2 ) and dissolved in 50ml deionized water, stirred until completely dissolved to obtain solution B, mixed 5mlA solution with 5mlB solution to obtain solution C, added 10mlC solution to 50mlGO solution to obtain D solution, and transferred 60mlD of the mixed solution to In a reaction kettle with polytetrafluoroethylene as the substrate, put the reaction kettle in an oven and keep it warm at 200 ° C for 12 hours, then cool the reaction kettle to room temperature naturally with the oven, and then ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com