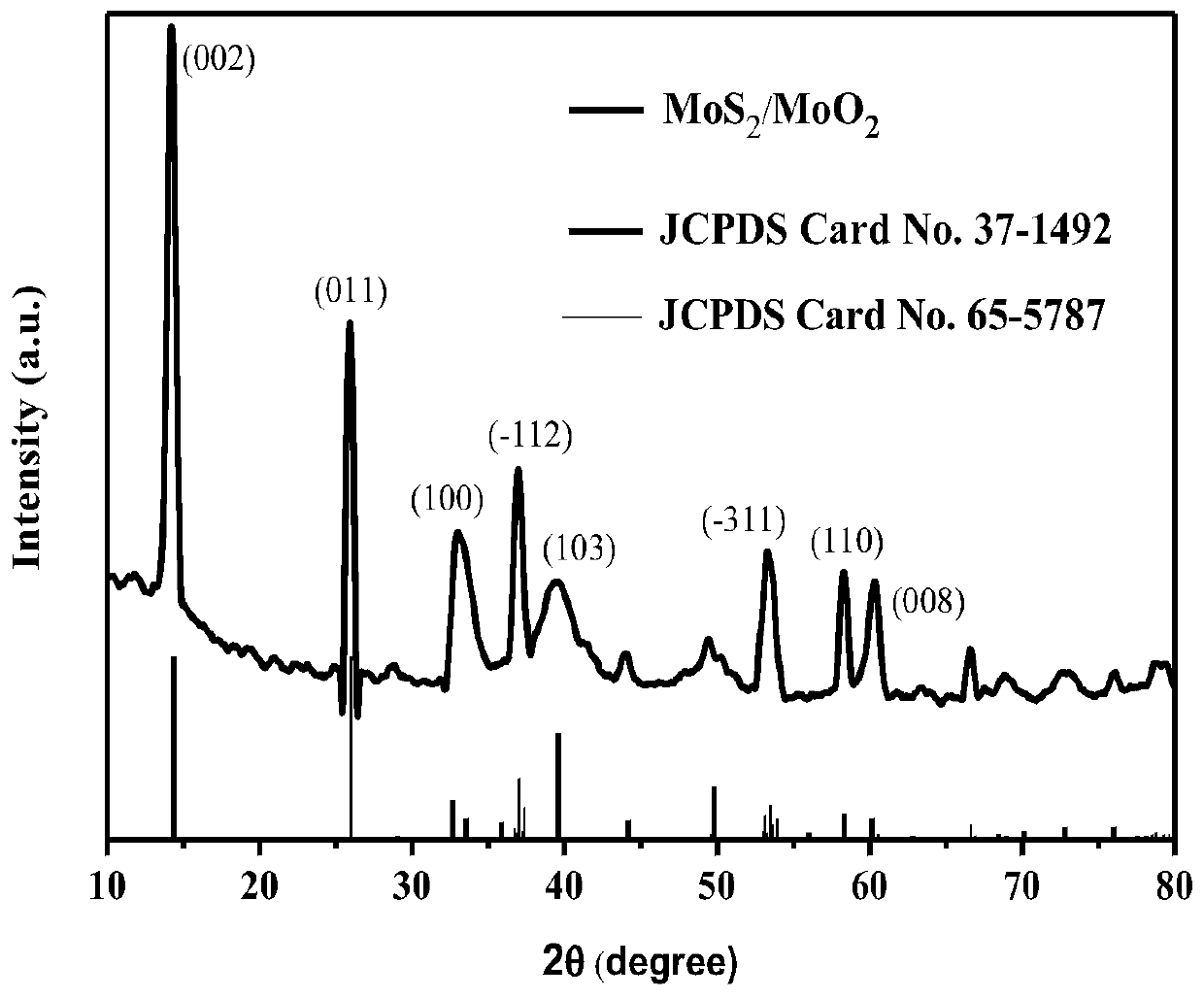

Method for preparing molybdenum disulfide/molybdenum dioxide composite material used for sodium ion negative electrode material

A technology of molybdenum disulfide and molybdenum dioxide, which is applied in nanotechnology for materials and surface science, battery electrodes, electrical components, etc., can solve problems such as difficulty in fully utilizing heterojunctions and uneven distribution, and achieve improved cycle The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1). Dissolve sodium molybdate dihydrate in deionized water, stir at 200r / min for 0.5h to prepare an aqueous solution of sodium molybdate with a concentration of 0.02mol / L;

[0024] 2). Add thiourea to the solution configured in step 1), the concentration of the thiourea aqueous solution is 0.02mol / L, continue to stir at 200r / min for 0.5h, add the surfactant cetyltrimethyl bromide Concentration of ammonium chloride, cetyltrimethylammonium bromide is 0.01mol / L, continue to stir at 200r / min for 0.5h;

[0025] 3). After the solution obtained in step 2) is transferred to the inner lining of a polytetrafluoroethylene hydrothermal reactor and sealed with a stainless steel reactor, the hydrothermal conditions: heating to 180° C. and holding for 18 hours. After the reaction is completed, cool to room temperature with the furnace, take out the reactant, centrifuge and wash 6 times with absolute ethanol and deionized water, and dry in vacuum at 60°C for 10 hours to obtain a molybdenum ...

Embodiment 2

[0029] 1). Dissolve sodium molybdate dihydrate in deionized water, stir at 300r / min for 1.0h to prepare an aqueous solution of sodium molybdate with a concentration of 0.060mol / L;

[0030] 2). Add thiourea to the solution configured in step 1), the concentration of thiourea aqueous solution is 0.06mol / L, continue to stir at 300r / min for 1.0h, then add the surfactant cetyltrimethyl bromide Concentration of ammonium chloride, cetyltrimethylammonium bromide is 0.025mol / L, continue stirring at 300r / min for 1.0h;

[0031] 3). After the solution obtained in step 2) is transferred to the inner lining of a polytetrafluoroethylene hydrothermal reactor and sealed with a stainless steel reactor, the hydrothermal conditions: heating to 200° C. and holding for 24 hours. After the reaction is completed, cool to room temperature with the furnace, take out the reactant, centrifuge and wash 7 times with absolute ethanol and deionized water, and vacuum dry at 70°C for 11 hours to obtain a molybdenum...

Embodiment 3

[0035] 1). Dissolve sodium molybdate dihydrate in deionized water and stir for 1.5h at 400r / min to prepare an aqueous solution of sodium molybdate with a concentration of 0.10mol / L;

[0036] 2). Add thiourea to the solution configured in step 1), the concentration of the thiourea aqueous solution is 0.1mol / L, continue to stir at 400r / min for 1.5h, add the surfactant cetyltrimethyl bromide The concentration of ammonium chloride, cetyltrimethylammonium bromide is 0.05mol / L, continue to stir at 400r / min for 1.5h;

[0037] 3). After the solution obtained in step 2) is transferred to the inner lining of a polytetrafluoroethylene hydrothermal reactor and sealed with a stainless steel reactor, the hydrothermal conditions: heating to 220° C. and holding for 36 hours. After the reaction, the reaction was cooled to room temperature with the furnace, the reactants were taken out, washed with absolute ethanol and deionized water for 8 times, and dried under vacuum at 80°C for 12 hours to obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com