Preparation method of supercapacitor electrode material multilayer petal-shaped nickel molybdate

A technology for supercapacitors and electrode materials, applied in the fields of hybrid capacitor electrodes, hybrid/electric double layer capacitor manufacturing, nanotechnology for materials and surface science, etc. problems, to achieve the effect of reducing internal resistance, good electrochemical stability, great research value and application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] A preparation method of supercapacitor electrode material multilayer petal-shaped nickel molybdate, comprising the following steps:

[0030] (1) Prepare the precursor solution with nickel nitrate hexahydrate, sodium molybdate dihydrate, deionized water and 15 ml 95% ethanol;

[0031] (2) Stir the solution obtained in step (1) with a glass rod for 15-20 minutes, then use an ultrasonic cleaner to accelerate the dissolution for 30-35 minutes, then transfer it to the inner tank of the high-pressure reactor, seal it, and put it into the electric heating constant temperature Carry out hydrothermal synthesis reaction in blast drying box;

[0032] (3) Take out the solution that has completely reacted in step (2) and cool it down to room temperature naturally, then use distilled water and absolute ethanol to perform centrifugal cleaning in a high-speed centrifuge at a certain speed;

[0033] (4) put the washed yellow-green substance into a vacuum drying oven to dry;

[0034] (...

Embodiment 1

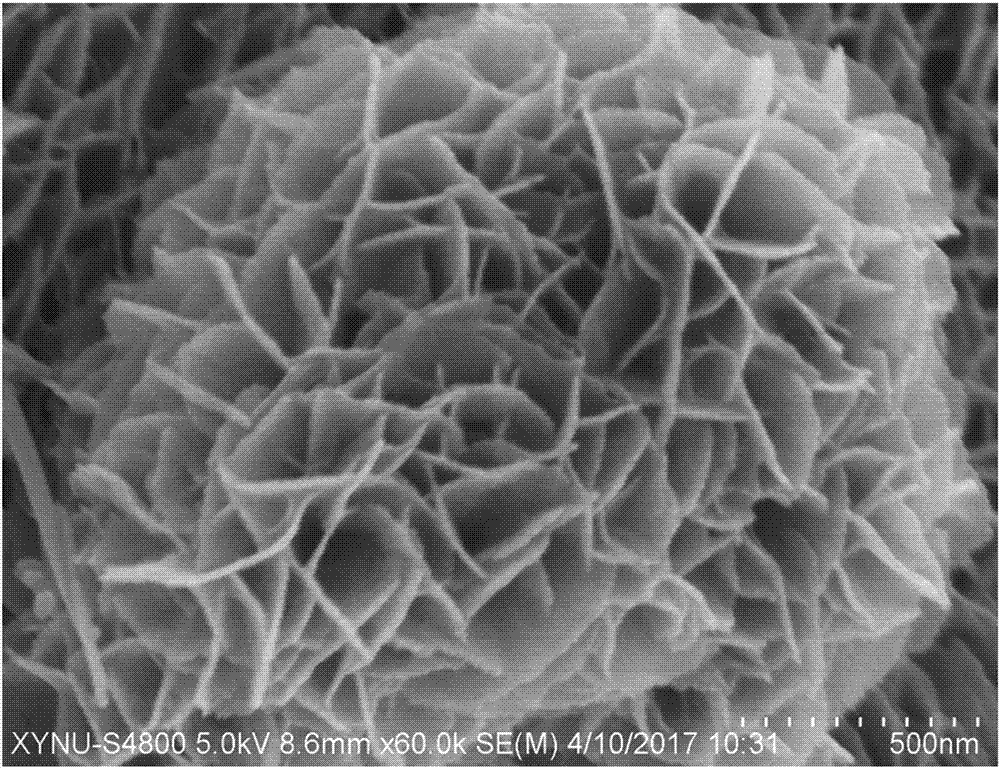

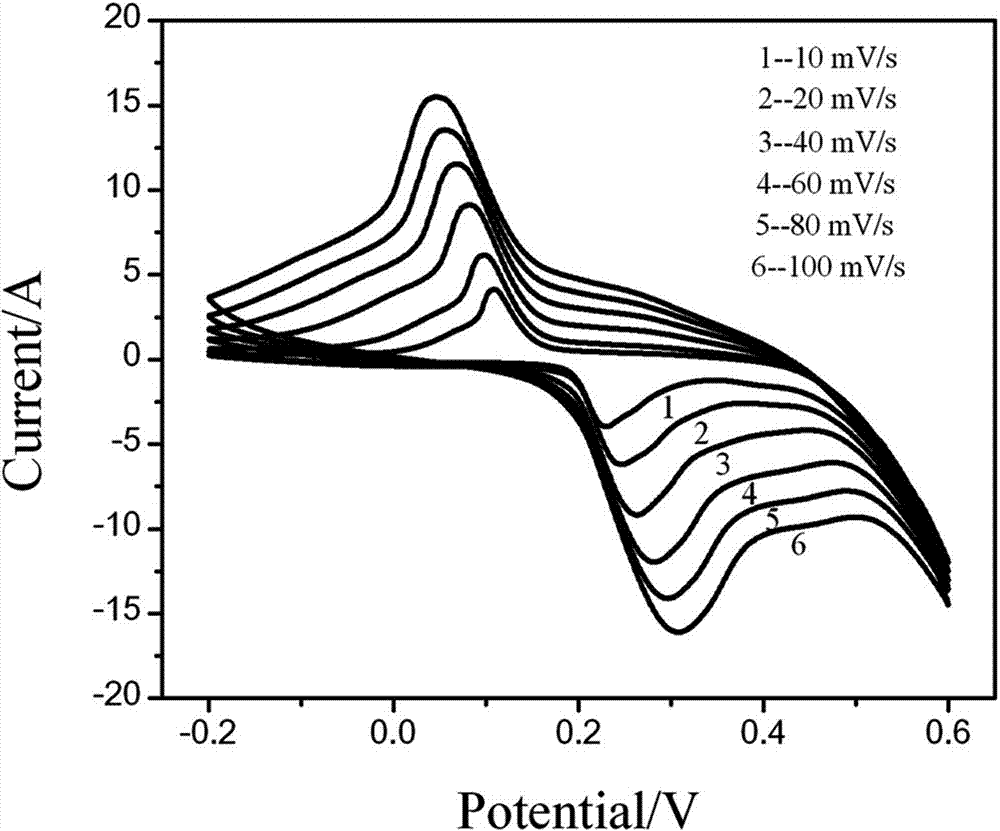

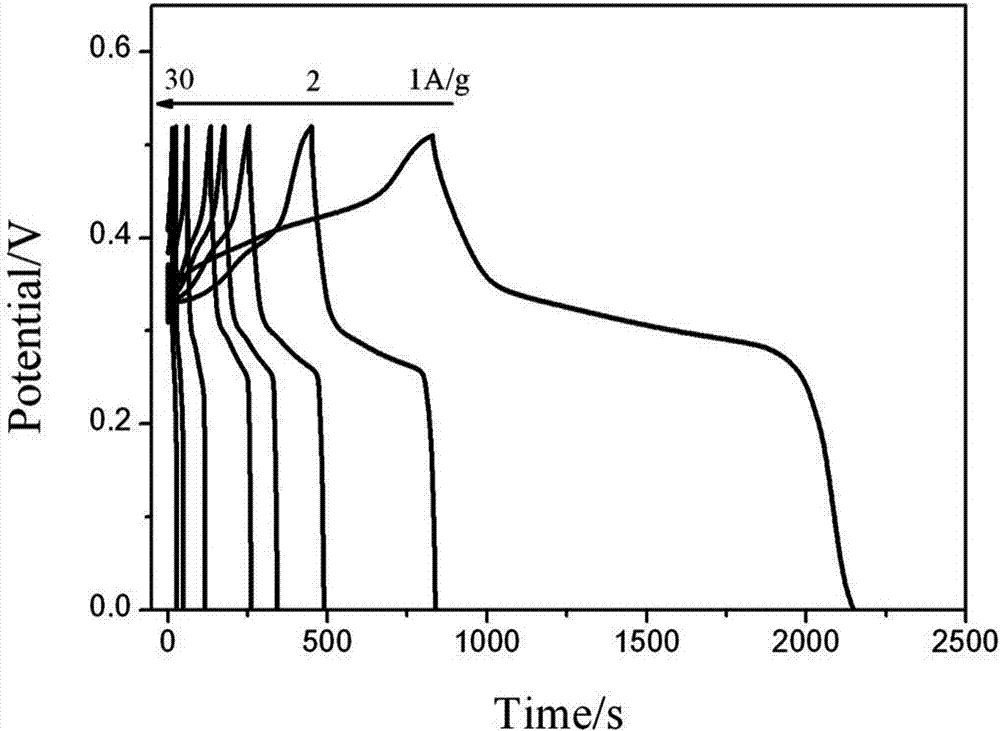

[0043] Accurately weigh 0.2908 g (1 mmol) of nickel nitrate hexahydrate and 0.2419 g (1 mmol) of sodium molybdate dihydrate, dissolve them in 15 ml of deionized water, add 15 ml of 95% ethanol, and stir with a glass rod 15-20 minutes, and then use an ultrasonic cleaner to accelerate the dissolution for 30-35 minutes, then transfer the mixed solution to the polytetrafluoroethylene liner of the high-pressure reactor, seal it, and put it into an electric heating constant temperature blast drying box Set the temperature at 160 °C and the time for 6 h for hydration thermal reaction; take out the completely reacted solution and cool it down to room temperature naturally, then use distilled water and absolute ethanol to set the speed at 7000 r / min in a high-speed centrifuge for 5 h Min is carried out centrifugal cleaning, first washes 3-5 times with deionized water, then washes 3-5 times with ethanol; The yellow-green material that washs clean is put into vacuum drying box and is drie...

Embodiment 2

[0045] Accurately weigh 0.2908 g (1 mmol) of nickel nitrate hexahydrate and 0.2419 g (1 mmol) of sodium molybdate dihydrate, dissolve them in 15 ml of deionized water, add 15 ml of 95% ethanol, and stir with a glass rod 15-20 minutes, then ultrasonically accelerate the dissolution for 30-35 minutes with an ultrasonic cleaner; transfer the mixed solution to the polytetrafluoroethylene liner of the high-pressure reactor, seal it well, and put it into an electric heating constant temperature blast drying box Set the temperature at 160 °C and the time for 6 h for hydration thermal reaction; take out the completely reacted solution and cool it down to room temperature naturally, then use distilled water and absolute ethanol to set the speed at 7000 r / min in a high-speed centrifuge for 5 h Min is carried out centrifugal cleaning, first washes 3-5 times with deionized water, then washes 3-5 times with ethanol; The yellow-green material that washs clean is put into vacuum drying box an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com