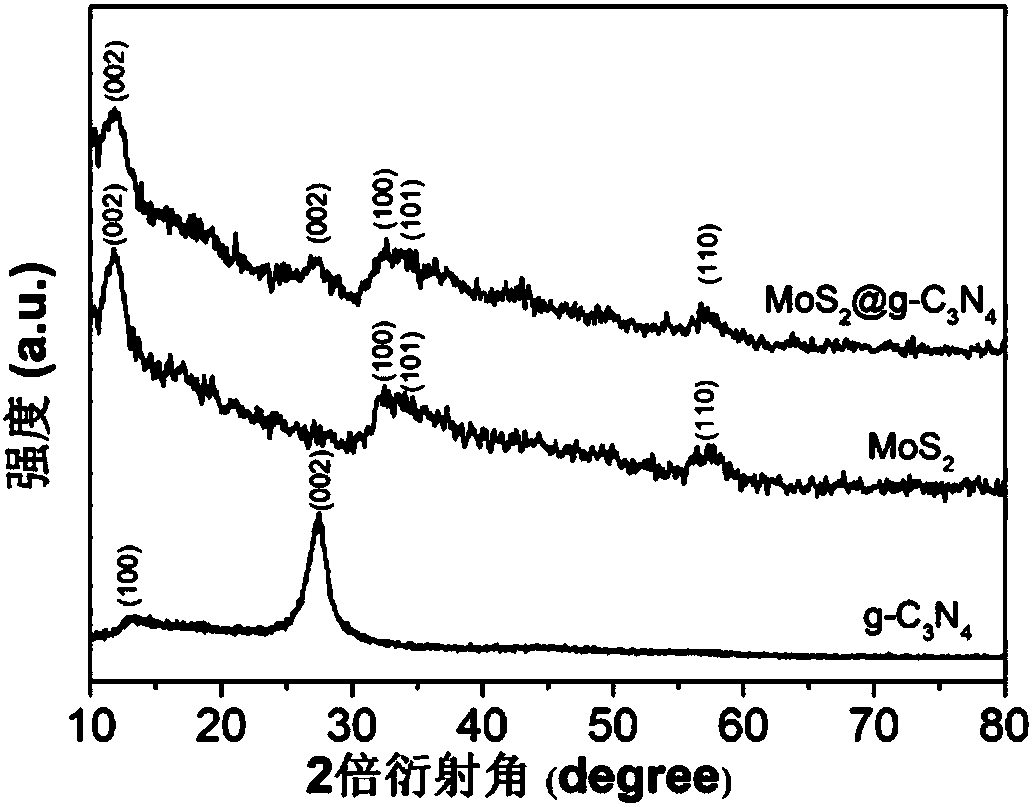

MoS2atg-C3N4 core-shell nanospheres and preparation method thereof

A technology of g-c3n4 and nanospheres, applied in the direction of nitrogen and non-metallic compounds, molybdenum sulfide, etc., to achieve the effect of mild conditions and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

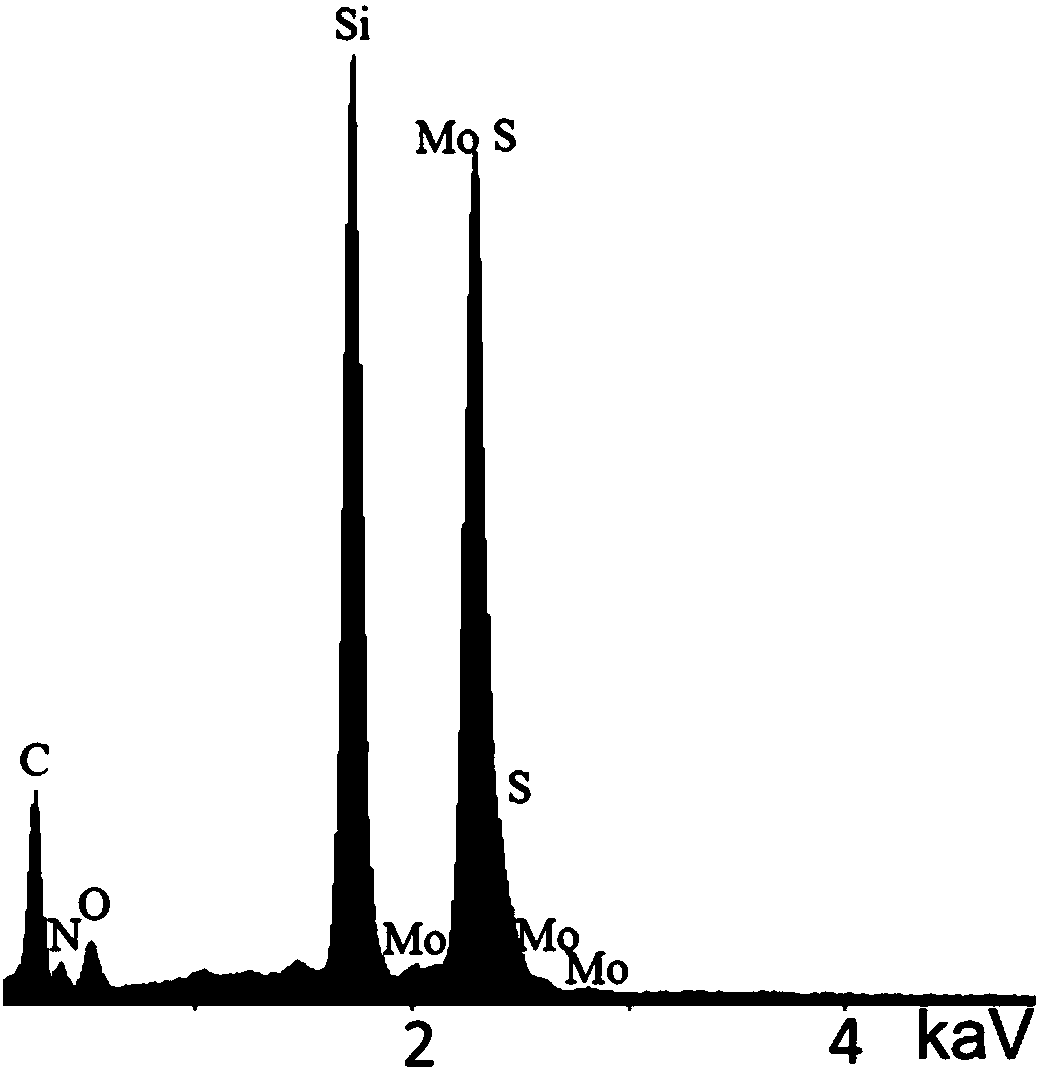

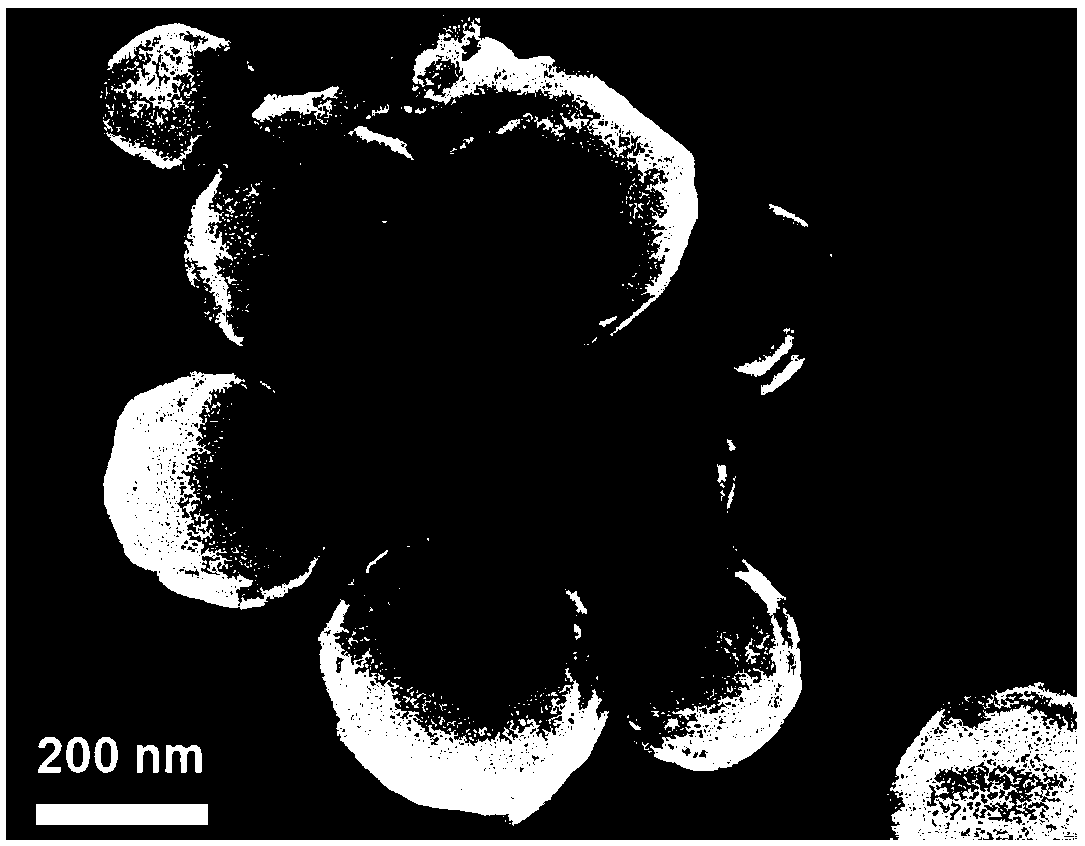

Embodiment 1

[0022] First prepare MoS 2 Nanospheres, take 0.3g of Na 2 MoO 4 2H 2 O, 0.76g of thiourea and 0.8g of PVP were completely dissolved in 80mL of deionized water, sealed in a 100mL polytetrafluoroethylene reactor, and hydrothermally reacted at 200°C for 12h. Centrifuge and wash with deionized water and absolute ethanol three times respectively, and dry in a blast drying oven at 80°C for 6 hours to obtain sample materials for use. Take an appropriate amount of melamine and put it into a crucible, then put it into a muffle furnace and calcine at 550°C for 2 hours at a heating rate of 20°C / min to obtain g-C 3 N 4 powder. Take 5mg of g-C 3 N 4 The powder is placed in 20ml of methanol and placed in a digitally controlled ultrasonic cleaner for 60 minutes until g-C 3 N 4 The powder is completely and uniformly dispersed in methanol solution. Take another 45mg of MoS 2 Magnetically stir in 10 ml of methanol until completely dissolved in methanol. Mix and disperse the two and ...

Embodiment 2

[0024]According to the hydrothermal reaction in the present invention in Example 1, the amount of thiourea was reduced to 0.19g, and the amount of other raw materials and experimental steps remained unchanged to obtain MoS 2 @g-C 3 N 4 Core-shell nanospheres.

Embodiment 3

[0026] According to the hydrothermal reaction in the present invention in Example 1, the amount of thiourea was reduced to 0.38g, and the amount of other raw materials and the experimental steps remained unchanged to obtain MoS 2 @g-C 3 N 4 Core-shell nanospheres.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com