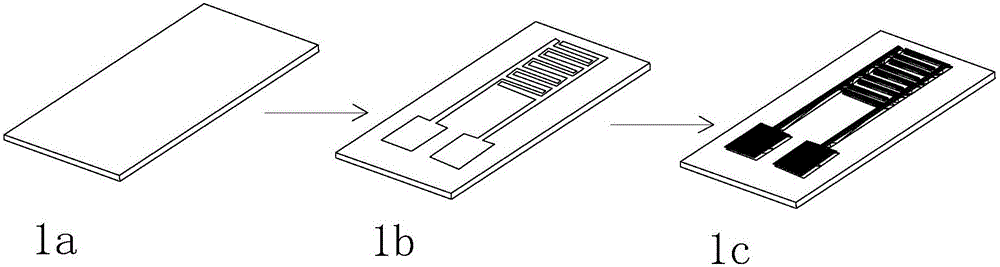

Pyrolytic carbon/molybdenum disulfide nanosheet/graphene composite material patterned micro-electrode and micro-processing technology thereof

A molybdenum disulfide and composite material technology, which is applied in metal material coating process, process for producing decorative surface effects, decorative arts and other directions, can solve the problems of difficult micro-devices and effective integration of micro-systems, etc., and achieve good application prospects , good electrochemical performance, the effect of wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1) Preparation of molybdenum disulfide nanosheet / graphene material:

[0024] 1.1. Dissolve 0.8g of sodium molybdate dihydrate in 30g of deionized water, stir to obtain a transparent solution, add 6mg of graphene powder to it, and ultrasonicate for 1 hour to obtain a uniform black solution;

[0025] 1.2, add 1.26g of thiourea to the black solution, stir for 30min, then ultrasonic for 30min to obtain the mixed solution;

[0026] 1.3. Transfer the mixed solution to a polytetrafluoroethylene-lined reactor with a volume of 50ml, and conduct a hydrothermal synthesis reaction at 200°C for 24 hours;

[0027] 1.4. Wash the hydrothermally synthesized product 6 times with centrifugation and ethanol. Each time, the centrifugation speed is 10000r / min, and the centrifugation time is 3min. , and then place the centrifuged precipitate in a drying oven and dry at 70°C for 24 hours to obtain a solid product;

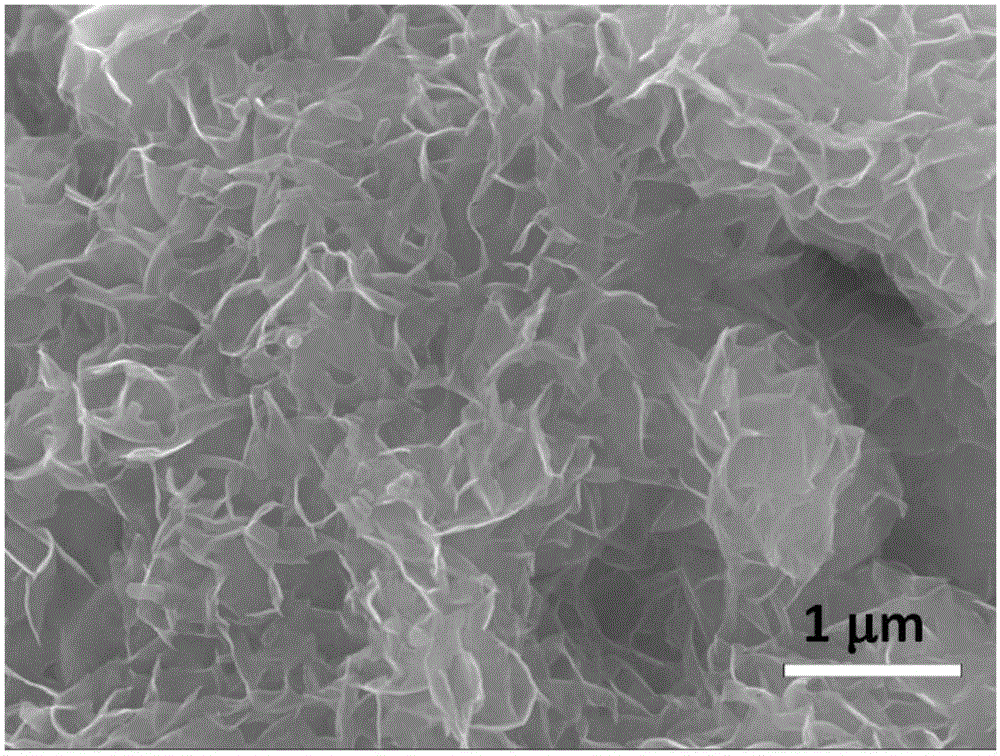

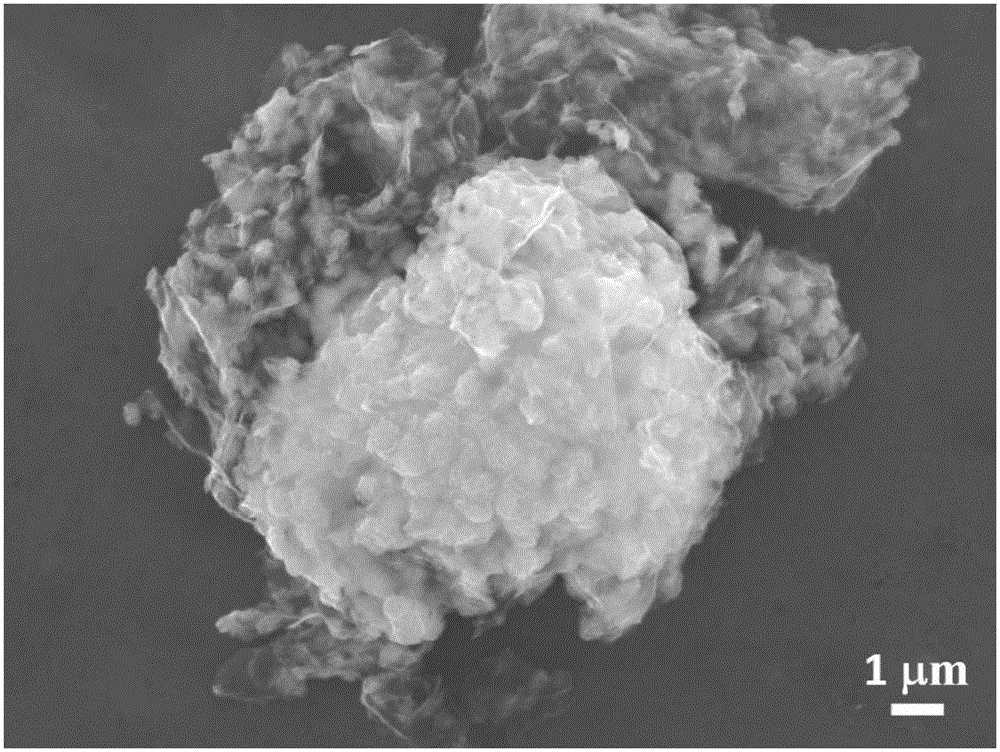

[0028] 1.5. Grinding the solid product to obtain molybdenum disulfide nanosh...

Embodiment 2

[0038] 1) Preparation of molybdenum disulfide nanosheet / graphene material:

[0039] 1.1. Dissolve 0.8g of sodium molybdate dihydrate in 60g of deionized water and stir to obtain a transparent solution; add 2mg of graphene powder to it and ultrasonicate for 1 hour to obtain a uniform black solution;

[0040] 1.2, add 1.2g thiourea to the black solution, stir for 30min, and then ultrasonic for 30min to obtain the mixed solution;

[0041] 1.3. Transfer the mixed solution to a polytetrafluoroethylene-lined reactor with a volume of 100ml, and conduct a hydrothermal synthesis reaction at 200°C for 24 hours;

[0042] 1.4. Wash the hydrothermally synthesized product 6 times with centrifugation and ethanol. Each time, the centrifugation speed is 10000r / min, and the centrifugation time is 3min. , and then place the centrifuged precipitate in a drying oven and dry at 70°C for 24 hours to obtain a solid product;

[0043] 1.5. Grinding the solid product to obtain the final product molybd...

Embodiment 3

[0053] 1) Preparation of molybdenum disulfide nanosheet / graphene material:

[0054] 1.1, 0.8g sodium molybdate dihydrate was dissolved in 20g deionized water, and stirred to obtain a transparent solution; 20mg graphene powder was added thereto, and ultrasonic treatment was performed for 1h to obtain a uniform black solution;

[0055] 1.2, add 1.4g thiourea to the black solution, stir for 30min, then ultrasonic for 30min to obtain the mixed solution;

[0056] 1.3. Transfer the mixed solution to a polytetrafluoroethylene-lined reactor with a volume of 50ml, and conduct a hydrothermal synthesis reaction at 200°C for 24 hours;

[0057] 1.4. Wash the hydrothermally synthesized product 6 times with centrifugation and ethanol. Each time, the centrifugation speed is 10000r / min, and the centrifugation time is 3min. , and then place the centrifuged precipitate in a drying oven and dry at 70°C for 24 hours to obtain a solid product;

[0058] 1.5. Grinding the solid product to obtain th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com