Alpha-molybdenum trioxide@molybdenum disulfide material as well as preparation method and application thereof

A technology of molybdenum disulfide and molybdenum trioxide, which is applied in the field of photocatalytic materials, can solve problems such as efficiency limitations, achieve the effects of reducing the band gap value, strong photocatalytic effect, and improving photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A preparation method of α-molybdenum trioxide@molybdenum disulfide material, comprising the following steps:

[0039] S1. Add 1.7g of sodium molybdate dihydrate into 140mL of water, ultrasonically dissolve, then add 10mL of concentrated nitric acid, and stir for 1 hour at 30°C to obtain molybdate nitric acid solution;

[0040] S2. The molybdate nitric acid solution is subjected to hydrothermal reaction, cooled after the end, and the supernatant is removed to obtain a precipitate, which is washed twice with water, washed twice with ethanol, and dried to obtain α-MoO 3 Precursor;

[0041] S3, 1g of α-MoO 3 The precursor, 5g of P123, 0.2g of sodium molybdate dihydrate and 0.1g of thiourea were added to 340mL of acetonitrile, and the reaction was stirred at 30°C for 2h to obtain α-MoO 3 slurry;

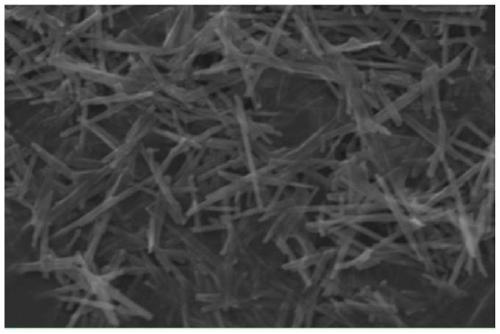

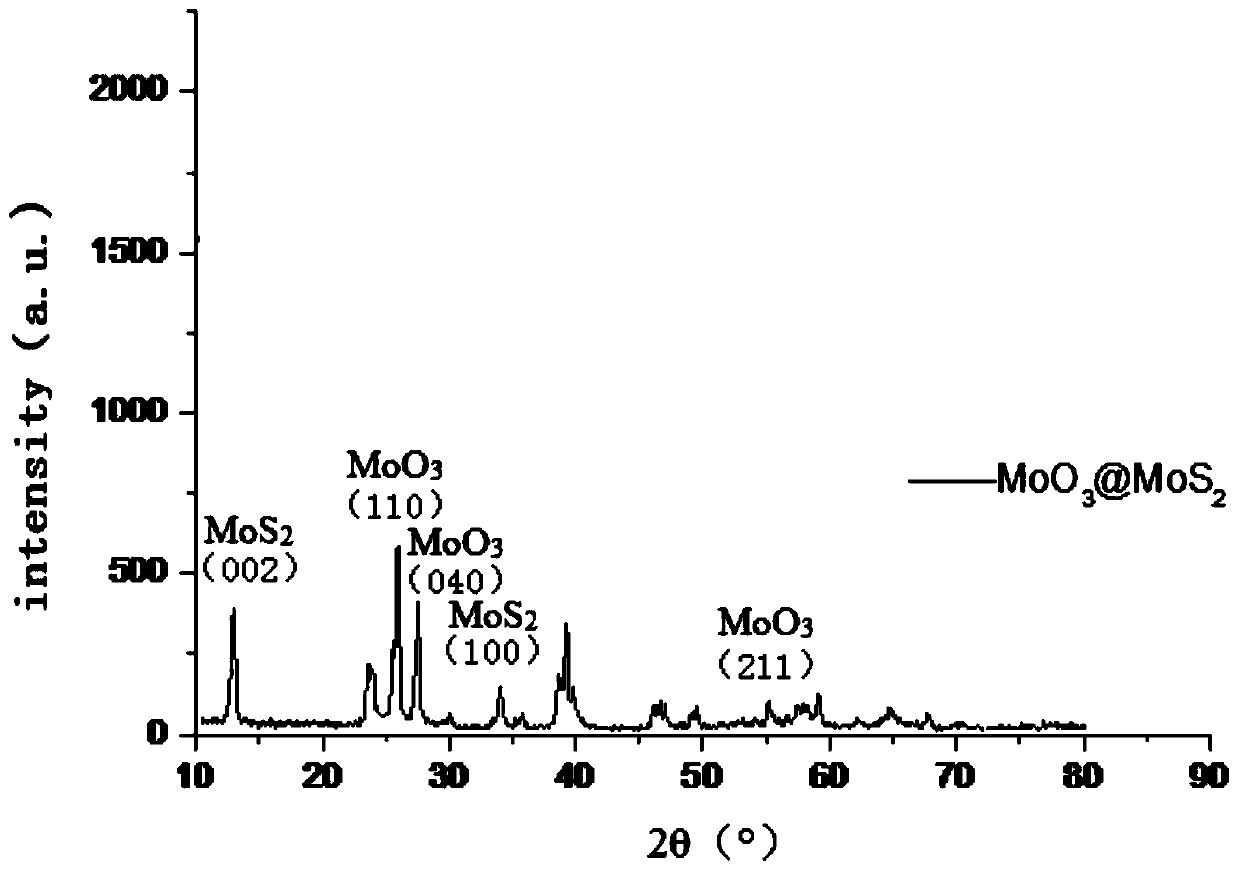

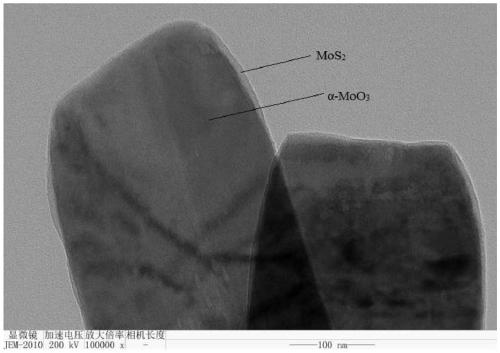

[0042] S4. Under the condition of 180°C, the α-MoO 3 The slurry was subjected to solvothermal reaction for 10 hours, cooled after the end, and the supernatant was removed to ob...

Embodiment 2

[0054] In this example, except 1g of α-MoO in S3 3 The precursor was replaced with 2g, P123 was 5g, sodium molybdate dihydrate was 3g, thiourea was 0.5g, acetonitrile was 500mL, the temperature of the hydrothermal reaction was 190°C, and the rest were the same as in Example 1.

Embodiment 3

[0056] In this embodiment, except that 1.7g of sodium molybdate dihydrate in S1 is replaced by 1g, the water is 100mL, the concentrated nitric acid is 5mL, the temperature of the hydrothermal reaction in S3 is 170°C, and the time is 9h, the rest are the same as in Example 1. same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com