Molybdenum sulfide multi-walled carbon nanotube gold modified glassy carbon electrode

A technology of multi-walled carbon nanotubes and glassy carbon electrodes, which is applied in the direction of material electrochemical variables, can solve problems such as poisoning and canceration, and achieve the effects of simple structure, high sensitivity, and improved electrocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (1) Weigh 1.0 mmol of sodium molybdate dihydrate and 4 mmol of thiourea in deionized water to form a mixed solution (1);

[0043] (2) Weigh 0.4 g of multi-walled carbon nanotubes, add them into the mixed solution (1), stir evenly, and form the mixed solution (2);

[0044] (3) Transfer the mixed solution (2) to a high-pressure reactor and react at 200 °C;

[0045] (4) After the reaction product of step (3) is centrifuged to remove moisture, first wash with ethanol to remove organics such as unreacted thiourea, and then wash with deionized water to remove unreacted inorganic ions until the pH value of the solution is 7.0, and the cleaned The final reaction product is placed in an oven and dried at 65°C to obtain a molybdenum sulfide multi-walled carbon nanotube composite;

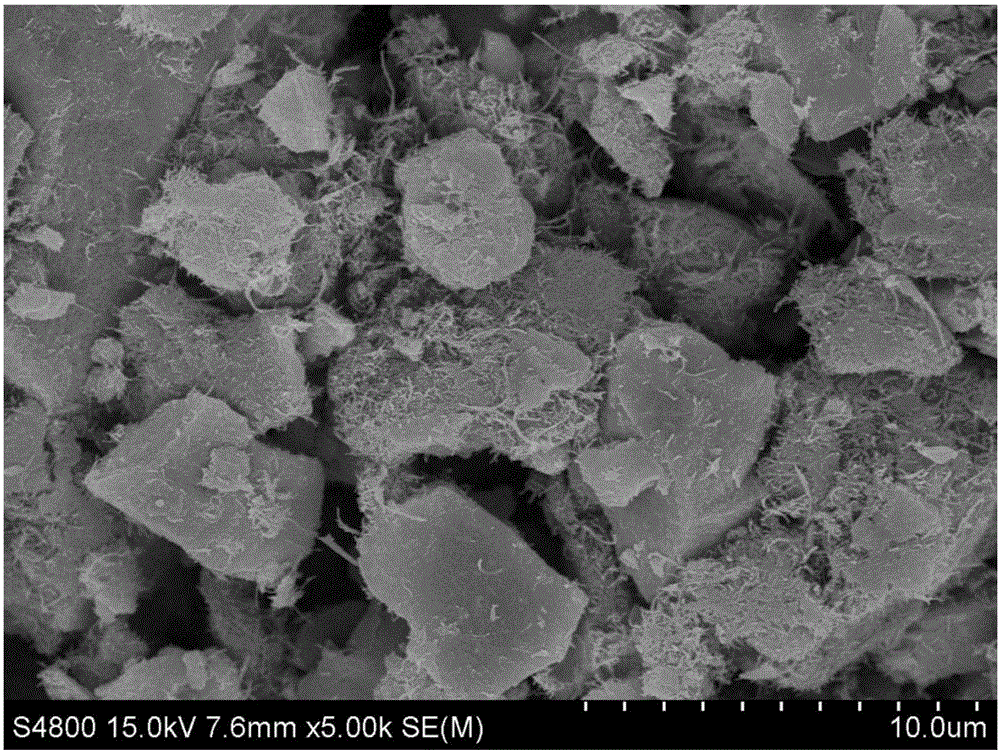

[0046] figure 1 Scanning electron micrograph of the molybdenum sulfide multi-walled carbon nanotube composite prepared for the present invention.

Embodiment 2

[0048] a) Weigh 4 mg of the molybdenum sulfide multi-walled carbon nanotube composite of Example 1 and add 80 microliters of perfluorosulfonic acid to a mixture of 0.25 microliters of deionized water and 0.75 milliliters of ethanol, and mix well by ultrasonic;

[0049] b) Apply an appropriate amount of 5 microliters of the homogeneous mixed solution obtained in step a) onto the surface of a clean glassy carbon electrode, and dry at room temperature;

[0050] c) the glassy carbon electrode obtained in step b), a platinum wire and a saturated calomel electrode are used to form a three-electrode system;

[0051] d) Put the three-electrode system into a sulfuric acid solution containing 3 mmol / L of chloroauric acid, electrolyze at -0.4 volts, after 20 seconds of electrolysis, remove the working electrode, and wash with deionized water to obtain Molybdenum sulfide multi-walled carbon nanotube gold nanocomposite modified glassy carbon electrode.

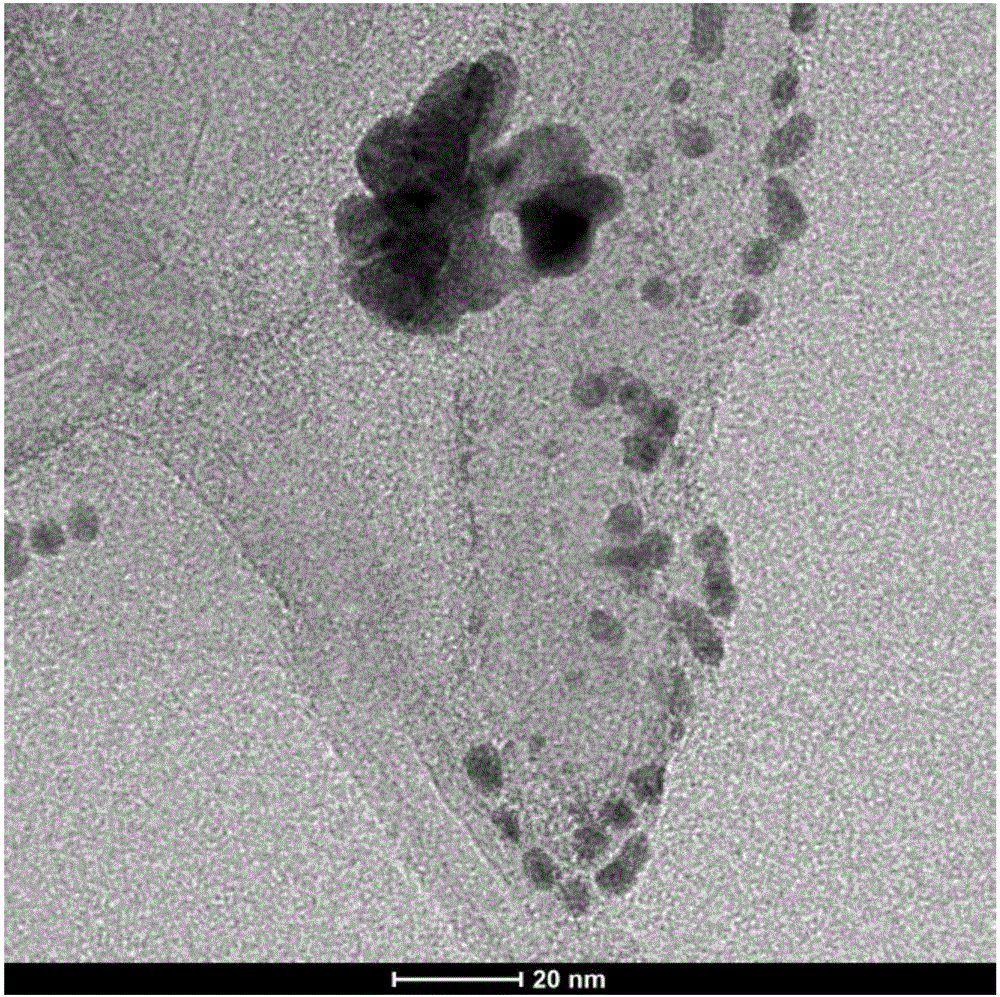

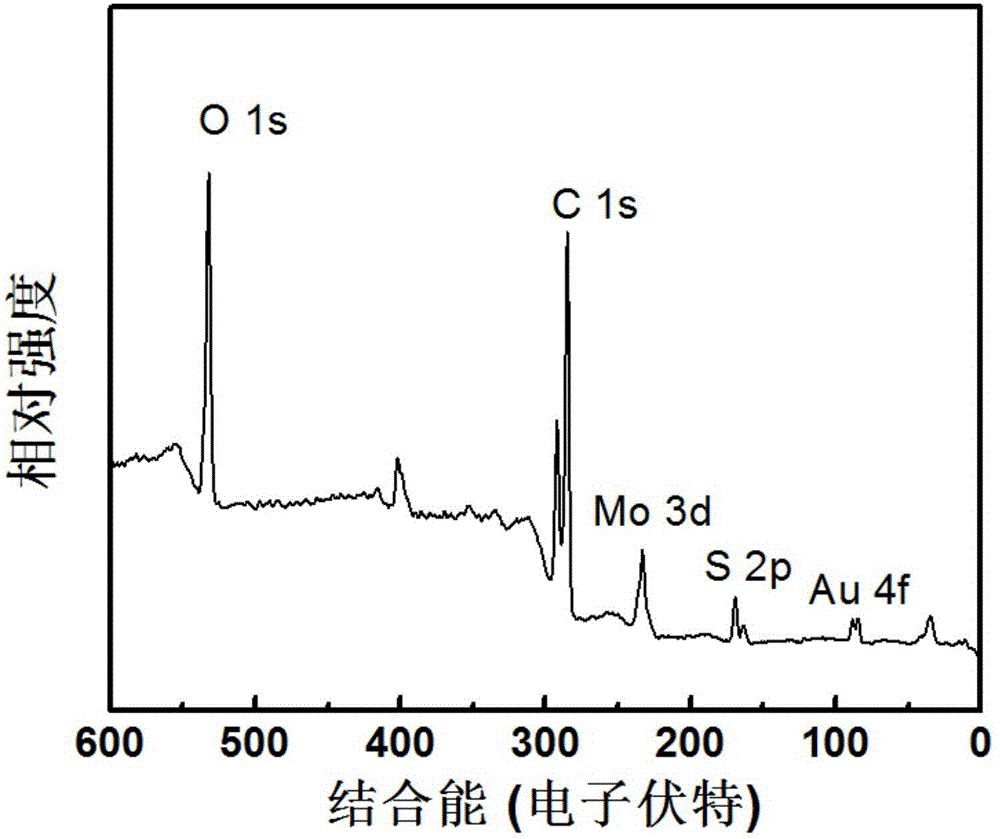

[0052] The morphology and material...

Embodiment 3

[0054] ① A three-electrode system composed of molybdenum sulfide multi-walled carbon nanotube gold nanocomposite modified glassy carbon electrode, platinum wire and saturated calomel electrode was placed in phosphate buffer solution containing different concentrations of nitrite, and determined by differential pulse voltammetry The catalytic performance of molybdenum sulfide multi-walled carbon nanotube gold nanocomposite to nitrite, the potential range of differential pulse voltammetry is 0~1.5 volts;

[0055]② Put the three-electrode system in step ① into a phosphate buffer solution with a constant concentration, add sodium nitrite solutions of different concentrations dropwise, measure the corresponding response current values of sodium nitrite solutions with different concentrations by constant potential method, and prepare The linear relationship graph between the concentration of nitrite and the response current was obtained, and the potential range of the constant pote...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com