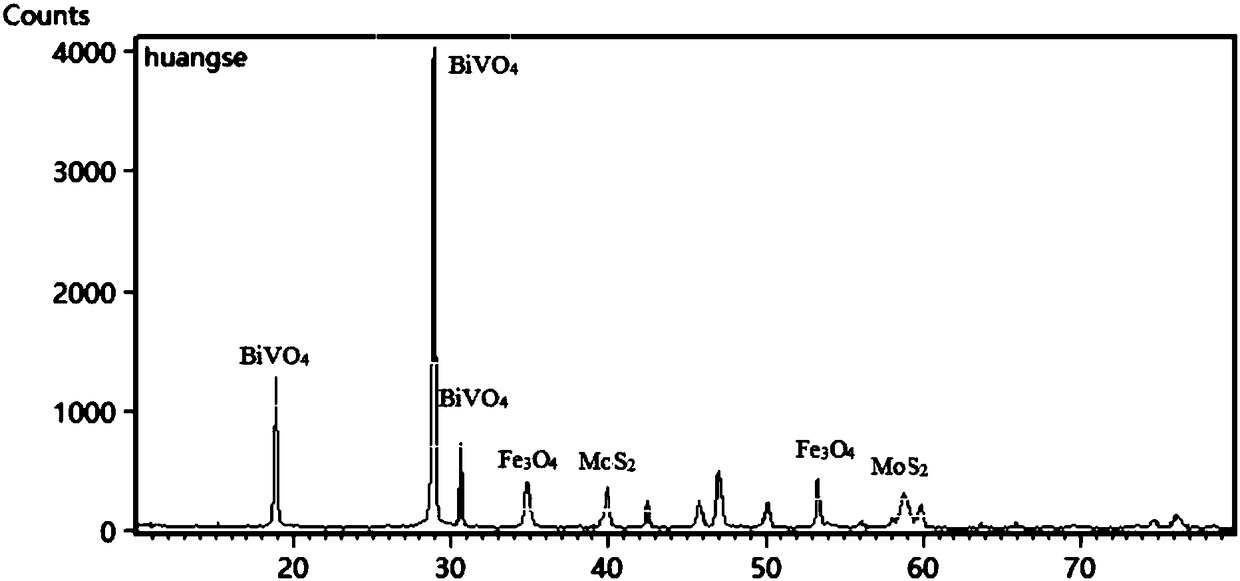

Fe3O4/MoS2/BiVO4 material preparing method, product and application of product

A composite material and reactant technology, which is applied to the preparation of Fe3O4/MoS2/BiVO4 and the field of composite materials, can solve the problems of narrow absorption light wavelength range, low photocatalytic efficiency, and inability to fully utilize sunlight, etc. The effect of improving the photocatalytic efficiency and improving the recycling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] Specifically, Fe 3 o 4 / MoS 2 / BiVO 4 The specific preparation method of the composite material includes: dissolving bismuth nitrate and metavanadic acid in deionized water, stirring magnetically for 30-40 minutes, and then adding Fe 3 o 4 / MoS 2 Vibrate the material ultrasonically for 20-30 minutes to obtain a mixed solution, pour the mixed solution into a polytetrafluoroethylene liner with a filling degree of 80%, put the polytetrafluoroethylene liner into a stainless steel reaction kettle, and place it in an electric thermostat to Heating at a heating rate of 5°C / min to 160-170°C, reacting for 15-17 hours; washing the reactants with distilled water and absolute ethanol respectively, and then centrifuging at a speed of 6000r / min for 5min, and placing the centrifuged product in vacuum drying In an oven, dry at 50°C for 3h, at 60°C for 3h, at 70°C for 3h, and at 80°C for 3h.

[0029] Among them, Fe 3 o 4 / MoS 2 Composite preparation methods include:

[0030] S...

Embodiment 1

[0040] Weigh 2.7g ferric chloride hexahydrate and 7.2g sodium acetate, add 0.6g polyethylene glycol, dissolve in 70mL ethylene glycol, carry out magnetic stirring for 30-40min, ultrasonic vibration for 10-20min, transfer it to In a polytetrafluoroethylene-lined reactor with a filling degree of 80%, react at 200°C for 8 hours, wash with deionized water and absolute ethanol three times, centrifuge at a speed of 6000r / min, and place in a vacuum oven Under the condition of vacuum degree of -0.1MPa, dry at 40°C for 5 hours, and dry at 50°C for 7 hours to obtain ferric oxide;

[0041] Weigh 0.36g sodium molybdate dihydrate, 2.38g ammonium molybdate tetrahydrate and 2.28g thiourea respectively, mix them, stir magnetically for 30min, then add 0.10g of prepared ferric oxide, and vibrate ultrasonically for 30min; It was transferred to a polytetrafluoroethylene-lined reactor and reacted at 200°C for 24 hours. After cooling to room temperature, it was washed three times with deionized wat...

Embodiment 2

[0046] The difference between this embodiment and embodiment 1 is: in the mixed solution of bismuth nitrate pentahydrate and ammonium metavanadate, Fe 3 o 4 / MoS 2 The amount of powder added is 0.107g, namely Bi 3+ with Mo 6+ Molar ratio = 15:1.

[0047] The prepared magnetic Fe 3 o 4 / MoS 2 / BiVO 4 The photocatalytic experiment of the composite photocatalyst was carried out under the same conditions, and the degradation rate of the tetracycline hydrochloride solution was 87.5% after 2 hours. After recovery and reuse, its photocatalytic treatment efficiency reaches about 80%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com