Preparation method for molybdenum-doped quaternary ammonium decatungstate high-efficiency photocatalyst

A decamerized tungstic acid and photocatalyst technology, applied in the preparation of organic compounds, carbon-based compounds, chemical instruments and methods, etc., to achieve the effects of high-efficiency doping, novel ideas, and excellent activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

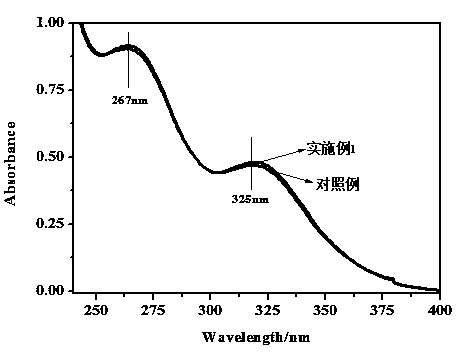

Image

Examples

Embodiment 1

[0019] Embodiment 1: the method for preparing molybdenum-doped n-tetrabutyl decapolytungstate quaternary ammonium salt of the present invention comprises the following steps:

[0020] (1) Add 6.6g of sodium tungstate dihydrate and sodium molybdate dihydrate in a certain molar ratio (Mo:W=0.01:9.99-0.03:9.97) to 20-50 o Stir and dissolve C in water (20-50mL), the solution concentration calculated by sodium tungstate is 0.4-1.0 mol / L, then slowly add 1-6 mol / L hydrochloric acid dropwise to adjust the pH value to 1.5-2.5;

[0021] (2) Heat the solution obtained in step (1) to 70-80°C for polymerization reaction under stirring, and polymerize for 15-20 minutes, during which time 1-6mol / L hydrochloric acid is used to adjust the pH value to 1.5-2.5. Then add n-tetrabutyl chloride or ammonium bromide salt solution with a concentration of 2-6mol / L (the molar weight is 0.5-1.5 times the molar weight of sodium tungstate), carry out ion exchange reaction at 80-100°C for 15-30min, gradual...

Embodiment 2

[0025] Example 2 (2-1~2-3) The method for preparing molybdenum-doped tetrabutyl decapolyammonium tungstate described in the invention includes the following steps: proceed according to the method of Example 1, the difference is that in The molar ratios of sodium tungstate dihydrate and sodium molybdate dihydrate in step (1) are respectively 0.005:9.995-0.008:9.992, 0.04:9.96-0.06:9.94, 0.07:9.93-0.1:9.9 (corresponding to implementation Example 2-1~2-3), the results are shown in Table 1.

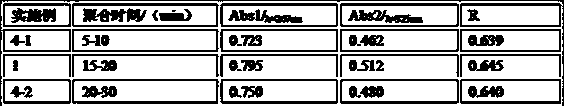

[0026] Table 1

[0027]

[0028] It can be seen from Table 1 that the R value of decapolyammonium tungstate doped with a small amount of molybdenum is equivalent to that of decapolyammonium tungstate without molybdenum, indicating that the doping of a small amount of molybdenum hardly affects the structure of decapolytungstic acid.

[0029] Example 3 (3-1~3-2): The method for preparing molybdenum-doped tetrabutyldecammonium tungstate salt according to the present invention includes the fo...

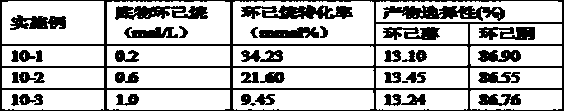

Embodiment 5

[0037]Example 5 (5-1~5-2): The method for preparing molybdenum-doped tetrabutyldecammonium tungstate salt according to the present invention includes the following steps: proceed according to the method of Example 1, the difference is , the pH values adjusted in step (2) were 1.5-2.0, 2.1-2.5 (respectively corresponding to Examples 5-1~5-2), and the specific results are shown in Table 4.

[0038] Table 4

[0039]

[0040] It can be seen from Table 4 that when the pH value is lower than 2.0, the prepared catalyst R is smaller, and when the pH value is 2.1-2.5, the quality is still inferior to that of the catalyst prepared when the pH value is 2.0-2.1.

[0041] Example 6 (6-1~6-3): According to the preparation method of Example 1, the difference is that in step (2) 1-6mol / L tetramethyl, tetraethyl Base, tetrapropyl chloride or ammonium bromide salt solution to obtain molybdenum-doped tetramethyl, tetraethyl, tetrapropyl ammonium decapolytungstate. The specific results are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com