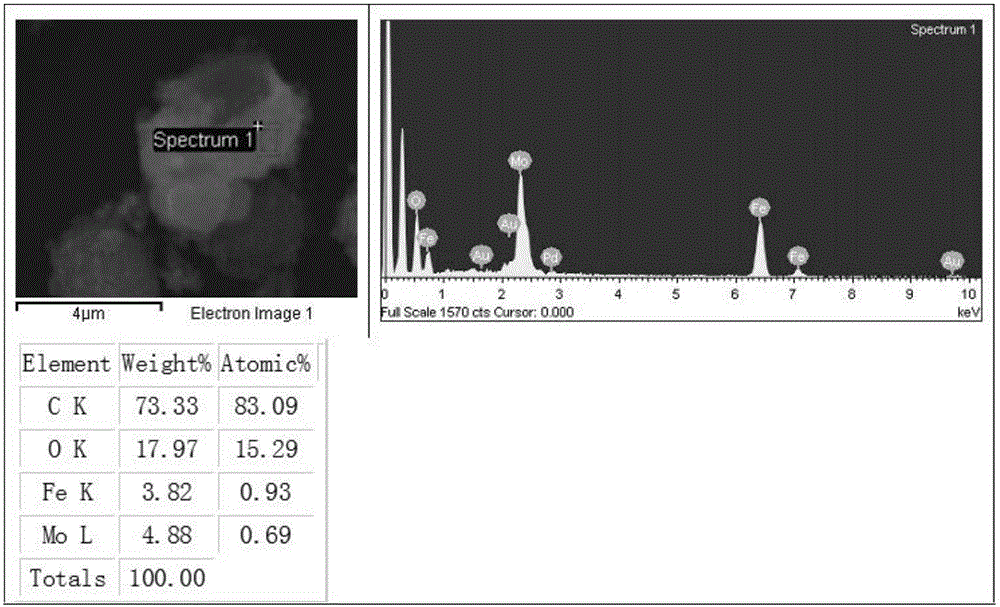

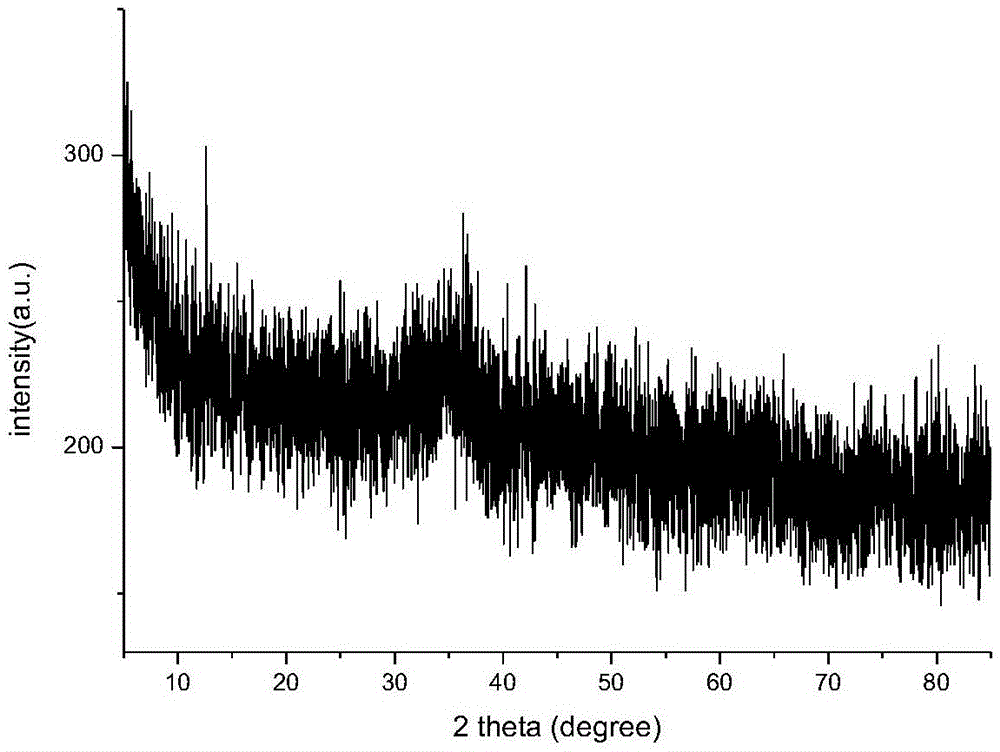

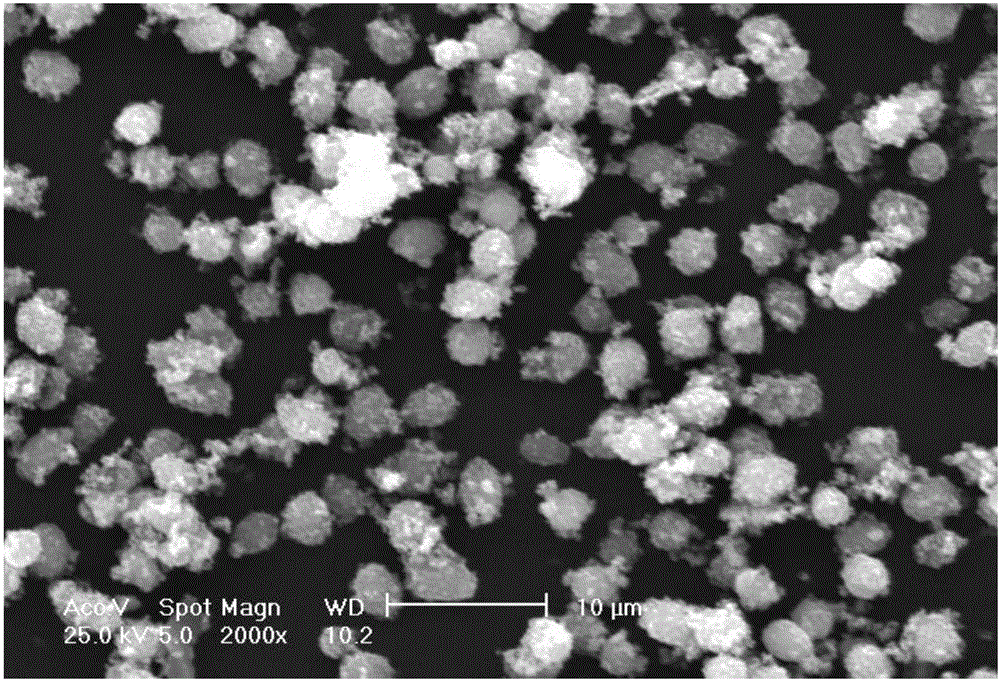

Biological carbon sphere supported FeMoO4 Fenton catalyst, preparation method and application

A technology of ferrous molybdate and biological carbon, which is applied in the field of molybdate, can solve the problems that biological carbon spheres have not yet been seen, the applicable pH range is small, and the cost of wastewater treatment is high, so as to promote effective precipitation, ensure purity, and reduce impurity particles Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Weigh the yeast powder and add an appropriate amount of deionized water, fully stir with a magnetic stirrer at room temperature for 30 minutes, then centrifuge at 3000r / m for 5 minutes, discard the supernatant, disperse and wash with deionized water again, and then centrifuge, repeat three times , then stir and dissolve the cleaned yeast with absolute ethanol, centrifuge at 3000r / m for 5min, discard the supernatant, disperse and activate with absolute ethanol again, repeat this operation twice; Deionized water, and add ferrous chloride tetrahydrate to the above solution, so that the concentration of ferrous chloride tetrahydrate is 0.03mol / L. Use a magnetic stirrer to fully stir at 40°C for 4 hours; then dissolve sodium molybdate dihydrate with deionized water and slowly add it to the above system, and add an appropriate amount of deionized water again to make the concentration of ferrous ions and molybdate ions in the solution equal to 0.03mol / L, stir the above solutio...

Embodiment 2

[0055] Weigh the yeast powder and add an appropriate amount of deionized water, fully stir with a magnetic stirrer at room temperature for 30 minutes, then centrifuge at 3000r / m for 5 minutes, discard the supernatant, disperse and wash with deionized water again, and then centrifuge, repeat three times , then stir and dissolve the cleaned yeast with absolute ethanol, centrifuge at 3000r / m for 5min, discard the supernatant, disperse and activate with absolute ethanol again, repeat this operation twice; Deionized water, and add ferrous chloride tetrahydrate to the above solution, so that the concentration of ferrous chloride tetrahydrate is 0.04mol / L. Use a magnetic stirrer to fully stir at 40°C for 4 hours; then dissolve sodium molybdate dihydrate with deionized water and slowly add it to the above system, and add an appropriate amount of deionized water again to make the concentration of ferrous ions and molybdate ions in the solution equal to 0.03mol / L, stir the above solutio...

Embodiment 3

[0057] Weigh the yeast powder and add an appropriate amount of deionized water, fully stir with a magnetic stirrer at room temperature for 30 minutes, then centrifuge at 3000r / m for 5 minutes, discard the supernatant, disperse and wash with deionized water again, and then centrifuge, repeat three times , then stir and dissolve the cleaned yeast with absolute ethanol, centrifuge at 3000r / m for 5min, discard the supernatant, disperse and activate with absolute ethanol again, repeat this operation twice; Deionized water, and ferrous chloride tetrahydrate was added to the above solution, so that the concentration of ferrous chloride tetrahydrate was 0.05mol / L. Use a magnetic stirrer to fully stir at 55°C for 3 hours; then dissolve sodium molybdate dihydrate with deionized water and slowly add it to the above system, and add an appropriate amount of deionized water again to make the concentration of ferrous ions and molybdate ions in the solution equal to 0.03mol / L, stir the above ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com