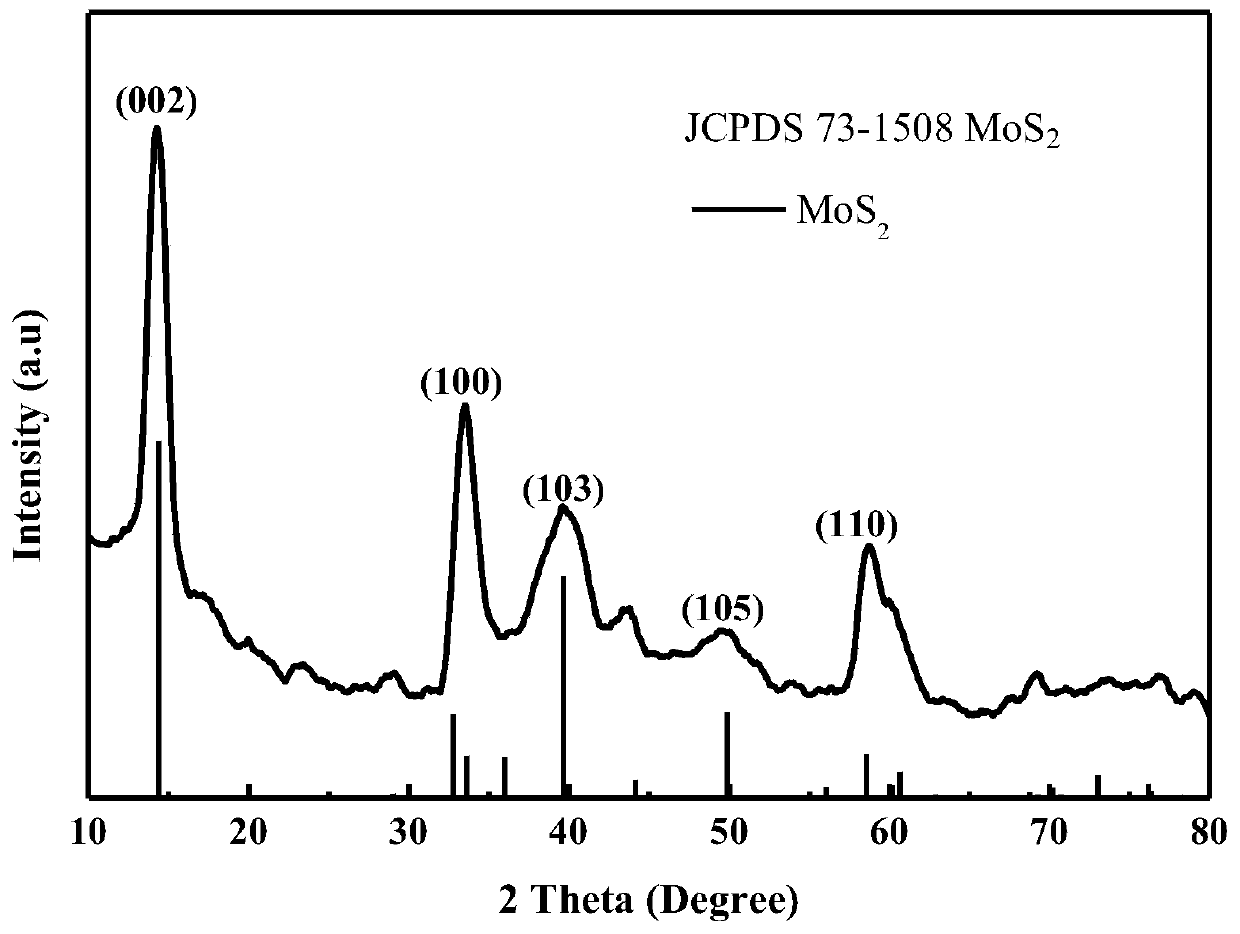

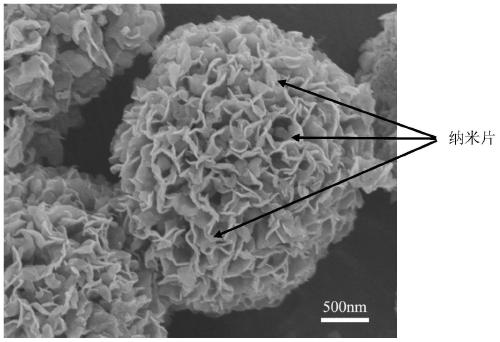

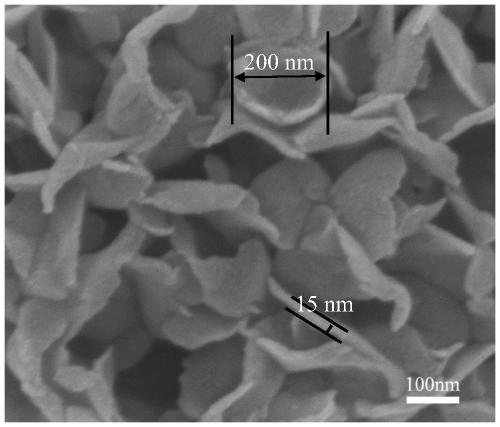

Preparation method of molybdenum disulfide material used for sodium lithium battery anodes

A molybdenum disulfide and sodium battery technology, used in molybdenum sulfide, battery electrodes, nanotechnology and other directions, can solve the problems of limited capacity and reduced theoretical specific capacity of composite materials, and achieve the effect of increasing specific surface area and improving cycle stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1). Dissolve sodium molybdate dihydrate in deionized water, stir at 200r / min for 0.5h, and prepare an aqueous sodium molybdate solution with a concentration of 0.02mol / L;

[0027] 2). Add thiourea to the solution configured in step 1), the concentration of the thiourea aqueous solution is 0.3mol / L, continue stirring at a speed of 200r / min for 0.5h, then add the surfactant hexadecyltrimethyl bromide Ammonium chloride, the concentration of cetyltrimethylammonium bromide is 0.01mol / L, continue to stir with 200r / min rotating speed for 0.5h;

[0028] 3). Add dropwise dilute hydrochloric acid with a concentration of 0.1mol / L to the solution obtained in step 2) to adjust pH=7, and continue to stir at a speed of 200r / min for 0.5h;

[0029] 4). Transfer the solution obtained in step 3) to the inner lining of a polytetrafluoroethylene hydrothermal reaction kettle, and seal it with a stainless steel reaction kettle. Hydrothermal conditions: heating to 180° C., and keeping it warm ...

Embodiment 2

[0033] 1). Sodium molybdate dihydrate was dissolved in deionized water, stirred at a speed of 300r / min for 0.8h, and an aqueous solution of sodium molybdate with a concentration of 0.05mol / L was prepared;

[0034]2). Add thiourea to the solution configured in step 1), the concentration of the thiourea aqueous solution is 0.1mol / L, continue stirring at a speed of 300r / min for 0.8h, then add the surfactant hexadecyltrimethyl bromide Ammonium chloride, the concentration of cetyltrimethylammonium bromide is 0.04mol / L, continue to stir with 300r / min rotating speed for 0.8h;

[0035] 3). Add dropwise dilute hydrochloric acid with a concentration of 0.5 mol / L to the solution obtained in step 2) to adjust pH=3, and continue to stir at a speed of 300 r / min for 0.8 h;

[0036] 4). Transfer the solution obtained in step 3) to the lining of a polytetrafluoroethylene hydrothermal reaction kettle, and seal it with a stainless steel reaction kettle. Hydrothermal conditions: heating to 200° C...

Embodiment 3

[0040] 1). Sodium molybdate dihydrate was dissolved in deionized water, and stirred at a speed of 400r / min for 1 hour to prepare an aqueous sodium molybdate solution with a concentration of 0.09mol / L;

[0041] 2). Add thiourea to the solution prepared in step 1), the concentration of thiourea aqueous solution is 0.225mol / L, continue to stir at 400r / min for 1h, then add the surfactant hexadecyl trimethyl bromide Ammonium, the concentration of cetyltrimethylammonium bromide is 0.09mol / L, continue to stir with 400r / min rotating speed for 1h;

[0042] 3). Add 1.0 mol / l dilute hydrochloric acid dropwise to the solution obtained in step 2) to adjust pH=1, and continue to stir at 400 r / min for 1 h;

[0043] 4). Transfer the solution obtained in step 3) to the inner lining of a polytetrafluoroethylene hydrothermal reaction kettle, and seal it with a stainless steel reaction kettle. Hydrothermal conditions: heating to 220° C., and keeping it warm for 12 hours. After the reaction, cool...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com