Method for efficiently synthesizing CuInSe2 quantum dots with chalcopyrite structures

A chalcopyrite and quantum dot technology is applied in the field of efficient synthesis of CuInSe2 quantum dots with chalcopyrite structure, which can solve the problems of large particle size, small output and high price of quantum dots, and achieves controllable particle size and particle size. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] An Efficient Synthesis of CuInSe with Chalcopyrite Structure 2 A method for quantum dots comprising the steps of:

[0053] 1) Weigh 1mmol of CuCl and 1mmol of InCl 3 4H 2 O was placed in a 50mL three-necked flask with a stirrer, 6mL oleylamine (OLA) and 10mL octadecene (ODE) were added, stirred and heated to 110°C, and the three-necked flask was evacuated for 30min (one-time vacuuming), and then introduced Argon, repeat the steps of vacuuming and argon a total of three times, continue to stir and heat to 155 ° C, stir for 10 min until the solid particles are completely dissolved, and obtain a dark red metal precursor solution (containing Cu + 、In 3+ cationic precursor solution), then lower the temperature of the precursor solution to 110°C, vacuumize for 15 minutes (secondary vacuum pumping), then pass argon, repeat the steps of vacuum pumping and argon for a total of three times;

[0054] 2) Weigh 2 mmol of Se powder into a 15 mL sample bottle, add 4 mL of oleylami...

Embodiment 2

[0060] An Efficient Synthesis of CuInSe with Chalcopyrite Structure 2 The method for quantum dots, its preparation method is roughly the same as Example 1, the difference is: the add-on of oleylamine (OLA) in step 1) is 5mL, the add-on of octadecene (ODE) is 10mL; Step 2) in oil The amounts of amine and cetyl mercaptan added were 3.8mL and 1.2ml respectively; in step 3), the temperature of the obtained reaction solution was raised twice, and the temperature was raised to 230° C., and then kept for 1 h.

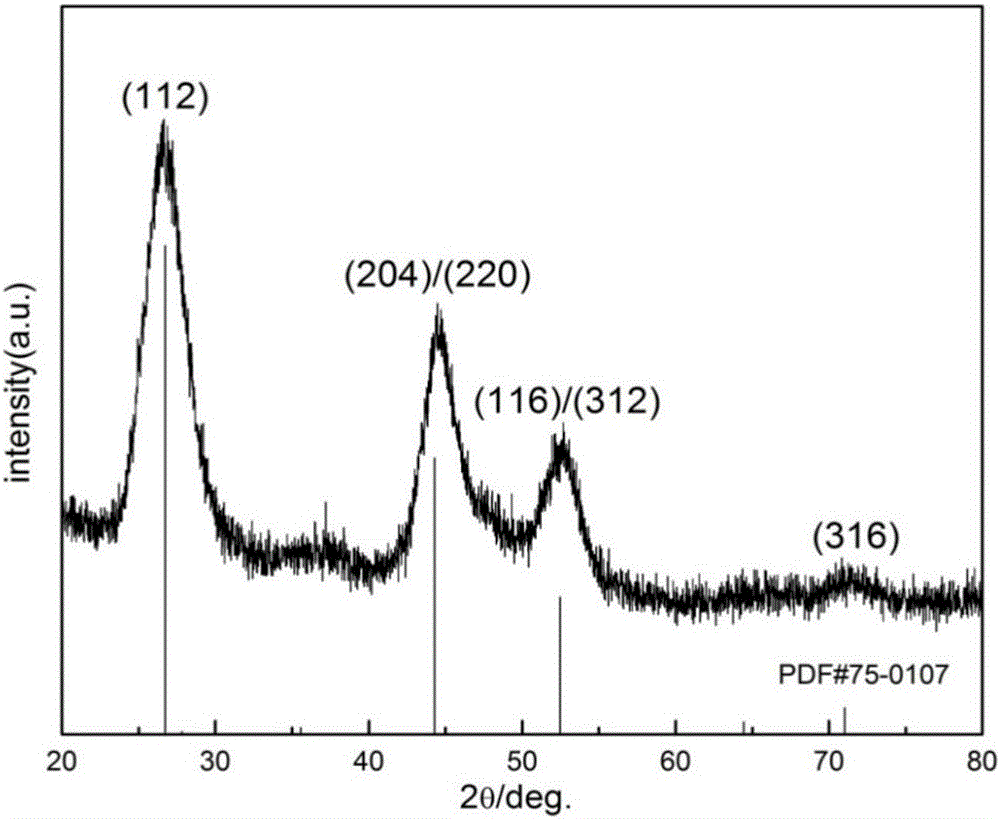

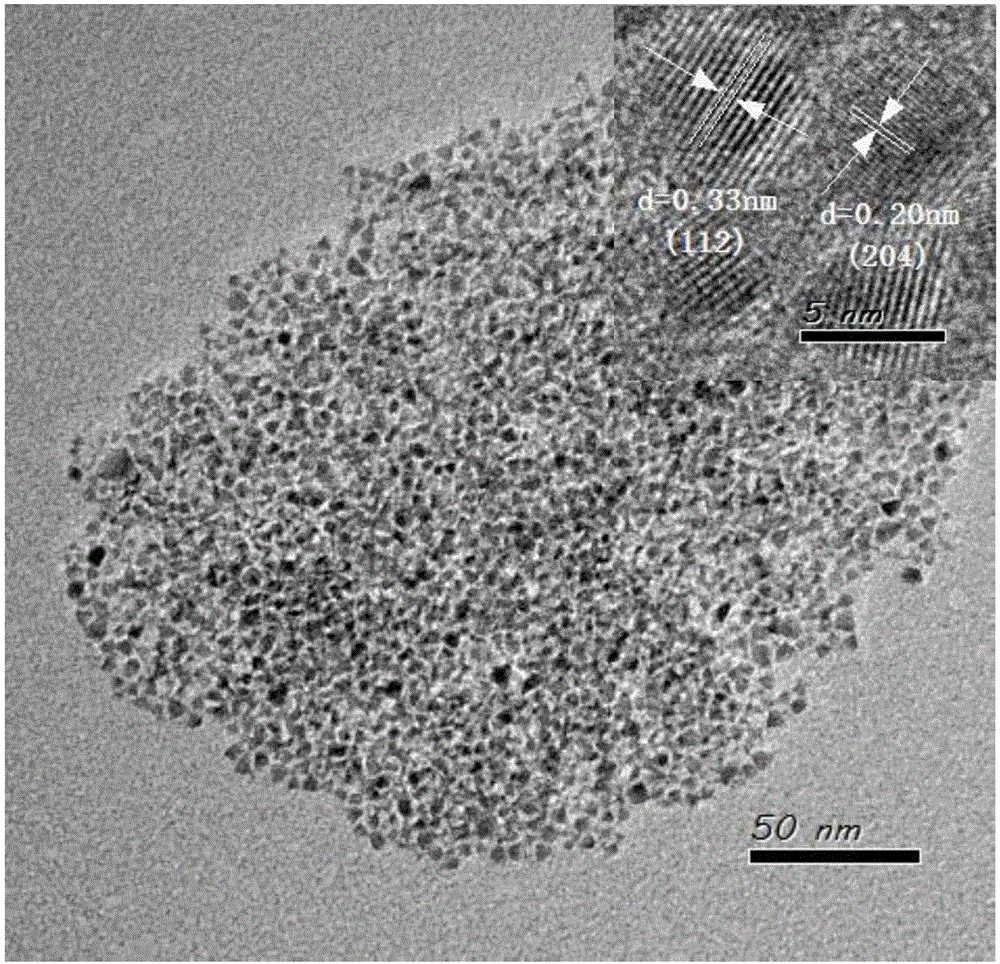

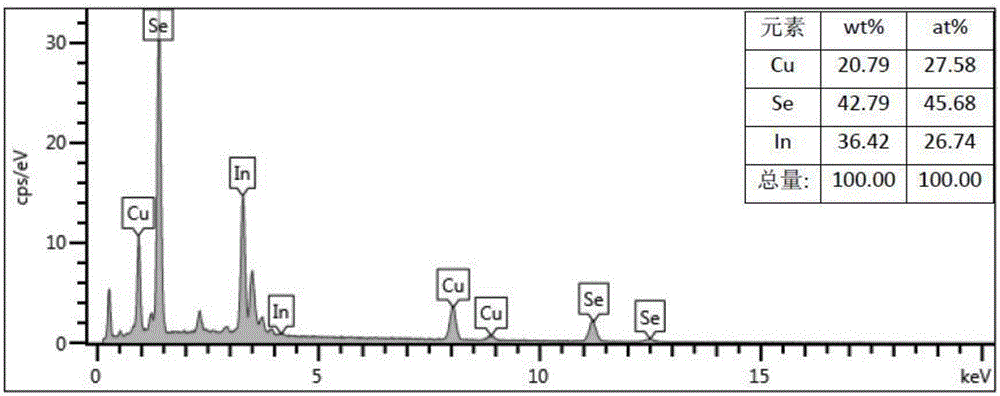

[0061] CuInSe obtained in this embodiment 2 The quantum dot powder was analyzed by X-ray diffraction, the results are shown in Figure 5 , the obtained product has a chalcopyrite structure, and the TEM spectrum shows that the obtained CuInSe 2 Quantum dots are triangular, square and spherical in shape, with few defects and good monodispersity, with an average size of 7nm (see Figure 6 ), EDS results show that the resulting CuInSe 2 The stoichiometric ratio of quantum dots...

Embodiment 3

[0064] An Efficient Synthesis of CuInSe with Chalcopyrite Structure 2 The method for quantum dots, its preparation method is roughly the same as Example 1, the difference is: the add-on of oleylamine (OLA) in step 1) is 4mL, and the add-on of octadecene (ODE) is 10mL; Step 2) in oil The amounts of amine and cetyl mercaptan added were 3.5mL and 1.5ml respectively; in step 3), the temperature of the obtained reaction solution was raised twice, and the temperature was raised to 210°C, and then kept for reaction for 1h.

[0065] CuInSe obtained in this embodiment 2 The quantum dot powder was analyzed by X-ray diffraction, the results are shown in Figure 9 , the figure shows that the resulting CuInSe 2 Quantum dots have a chalcopyrite structure. The TEM spectrum shows that the obtained CuInSe 2 The quantum dots are triangular in shape, have few defects and have good monodispersity, and the average grain size is 4.2nm (see Figure 10 ).

[0066] CuInSe obtained in this embodi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com