Self-adaptable spring stern door of asphalt pavement milling machine

An adaptive technology for asphalt pavement, which is applied in the field of construction machinery, can solve the problems of low recovery rate of milling materials, large scraping resistance, uneven milling road grooves, etc., so as to improve operation efficiency and quality, reduce external resistance, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

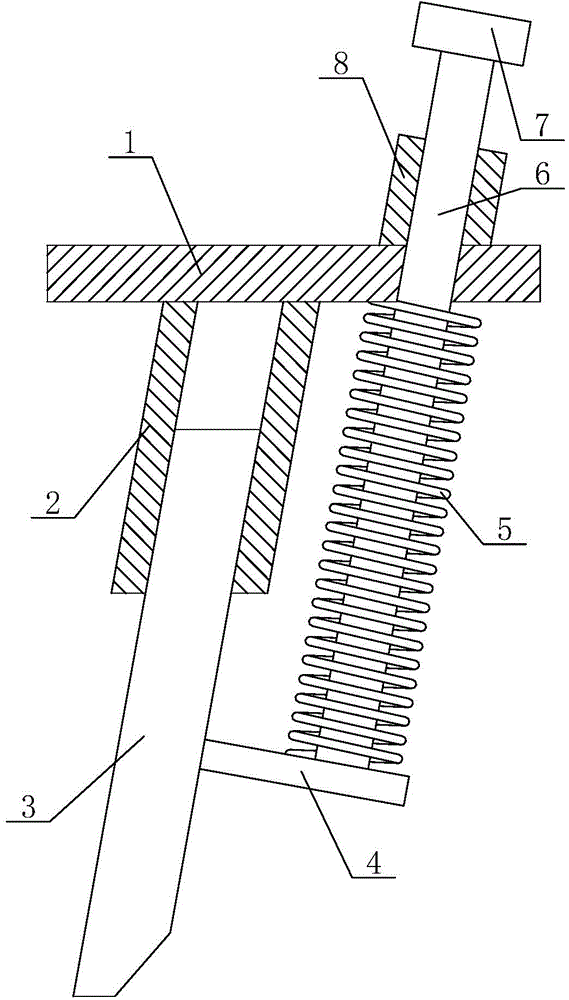

[0020] like figure 1 The spring self-adaptive tailgate of an asphalt road milling machine shown includes a frame 1 for fixed support and a door panel 3 for exerting pressure on the bottom surface of the milling groove and recovering the milling material. The guide groove 2 of the door panel 3, the spring 5 for providing the driving force for the door panel 3, and the sliding shaft 6 for installing the spring 5; the guide groove is fixedly installed on the lower side of one end of the frame 1 2. The door panel 3 is slidably installed in the guide groove 2, a guide sleeve 8 is fixedly installed on the upper side of the other end of the frame 1, and the sliding shaft 6 is slidably installed in the guide sleeve 8, The upper end of the sliding shaft 6 is fixedly installed with a limit stopper 7, the spring 5 is sleeved on the sliding shaft 6, the lower end of the sliding shaft 6 is fixedly connected with one end of the fixed connecting plate 4, and the fixed connecting plate The o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com