Flame retardant phase change microcapsule and its preparation method and use

A technology of phase change microcapsules and flame retardants, which is applied in the field of power batteries, flame retardant phase change microcapsules and their preparation, and preparation of flame retardant phase change microcapsules. Problems such as uneven distribution of enthalpy value of microcapsules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

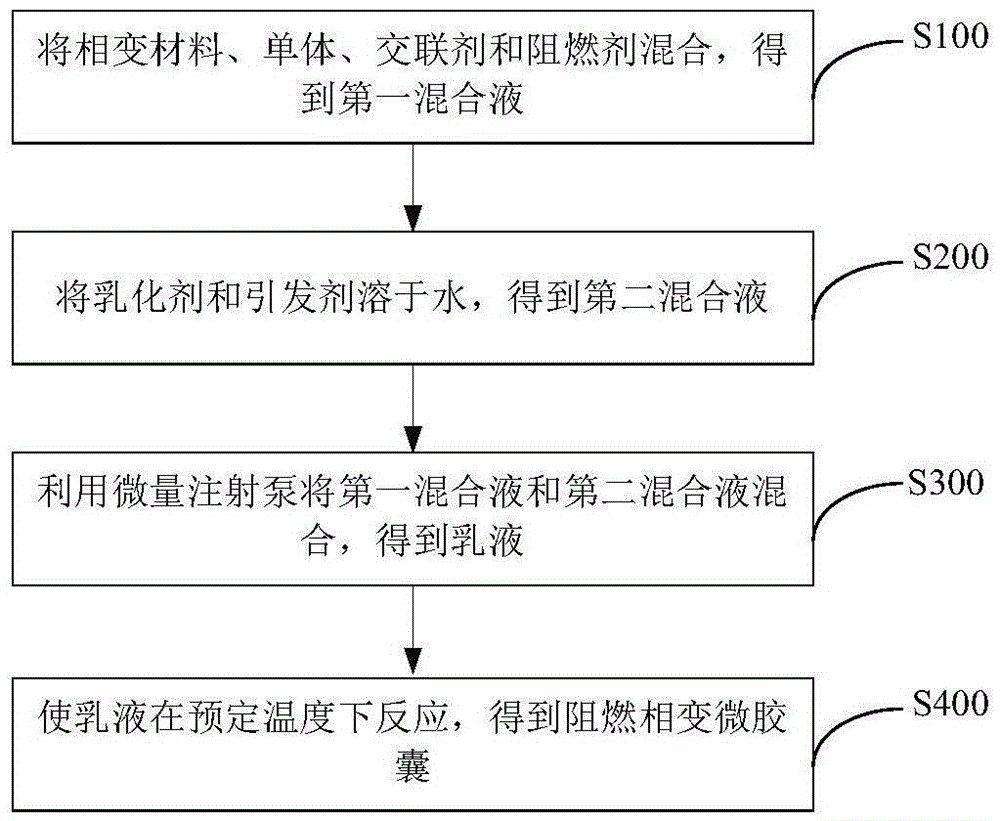

Method used

Image

Examples

Embodiment 1

[0046] Heat 5 g of paraffin wax with a phase transition temperature of 25° C. to 50° C., add 1 g of chlorinated paraffin, 2 g of styrene, and 1 g of divinylbenzene, and mix evenly. The obtained mixed solution is called mixed solution one.

[0047] The aqueous solution of 10 g of emulsifier was added into 81 g of water, and 0.06 g of water-soluble initiator potassium persulfate was added, and the obtained mixed solution was used as mixed solution 2.

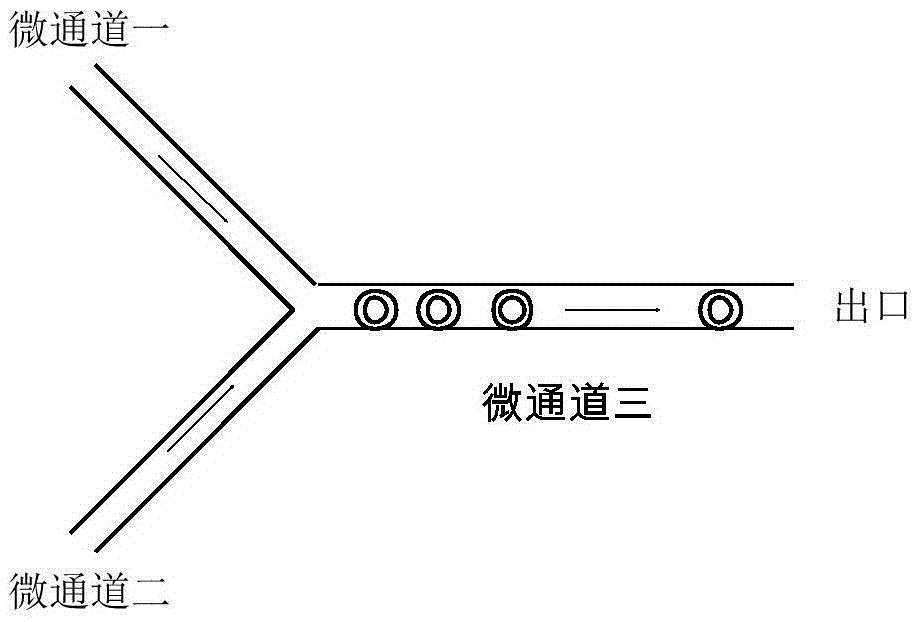

[0048] The mixed solution 1 and mixed solution 2 obtained above were injected into microchannels 1 and 2 with a microsyringe pump, and the injection flow rates were controlled to be 50 μL / min and 100 μL / min, respectively.

[0049] Receive the emulsion formed after the mixed solution 1 and 2 are mixed, raise the temperature of the emulsion to 70° C., and react for 8 hours under nitrogen to obtain the flame-retardant phase-change microcapsules.

[0050] The particle size of the obtained flame-retardant phase-change microcapsules was...

Embodiment 2

[0052] Heat 6 g of alkane mixture with 12 to 25 carbon atoms until it melts, add 0.5 g of chlorinated paraffin, 1 g of acrylate, and 0.5 g of ethylene glycol dimethacrylate, and mix evenly. The obtained mixed solution is called mixed solution 1.

[0053] The aqueous solution of 15g of emulsifier was added into 70g of water, and 0.08g of water-soluble initiator potassium persulfate was added, and the obtained mixed solution was used as mixed solution 2.

[0054] The mixed solution 1 and mixed solution 2 obtained above were injected into microchannels 1 and 2 with a microsyringe pump, and the injection flow rates were controlled to be 25 μL / min and 150 μL / min, respectively.

[0055] Receive the emulsion formed after the mixed solution 1 and 2 are mixed, raise the temperature of the emulsion to 100°C, and react under nitrogen for 10 hours to obtain the flame-retardant phase-change microcapsules.

[0056] The particle size of the obtained flame-retardant phase-change microcapsules...

Embodiment 3

[0058] Heat 4g of paraffin wax with a phase transition temperature of 25°C to 50°C, add 1.5g of chlorinated paraffin, 3g of methyl methacrylate, and 1.5g of divinylbenzene, and mix evenly. The obtained mixed solution is called mixed solution 1.

[0059] The aqueous solution of 5 g of emulsifier was added into 90 g of water, and 0.04 g of water-soluble initiator potassium persulfate was added, and the obtained mixed solution was used as mixed solution 2.

[0060] The mixed solution 1 and mixed solution 2 obtained above were injected into microchannels 1 and 2 with a microsyringe pump, and the injection flow rates were controlled to be 15 μL / min and 75 μL / min, respectively.

[0061] Receive the emulsion formed after the mixed solution 1 and 2 are mixed, raise the temperature of the emulsion to 50° C., and react under nitrogen for 6 hours to obtain the flame-retardant phase-change microcapsules.

[0062] The particle size of the obtained flame-retardant phase-change microcapsules...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com