Novel piezoelectric driving microfluid mixer and preparation technology thereof

A piezoelectric drive and mixer technology, applied in the field of microfluidics, can solve the problems of inconvenient mass production, poor biocompatibility, inconvenience, etc., and achieve the effects of good mixing effect, low cost and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

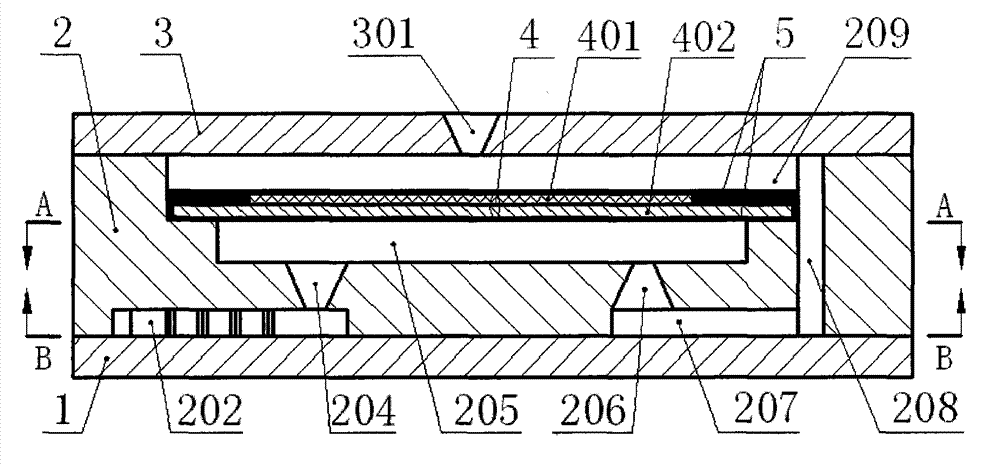

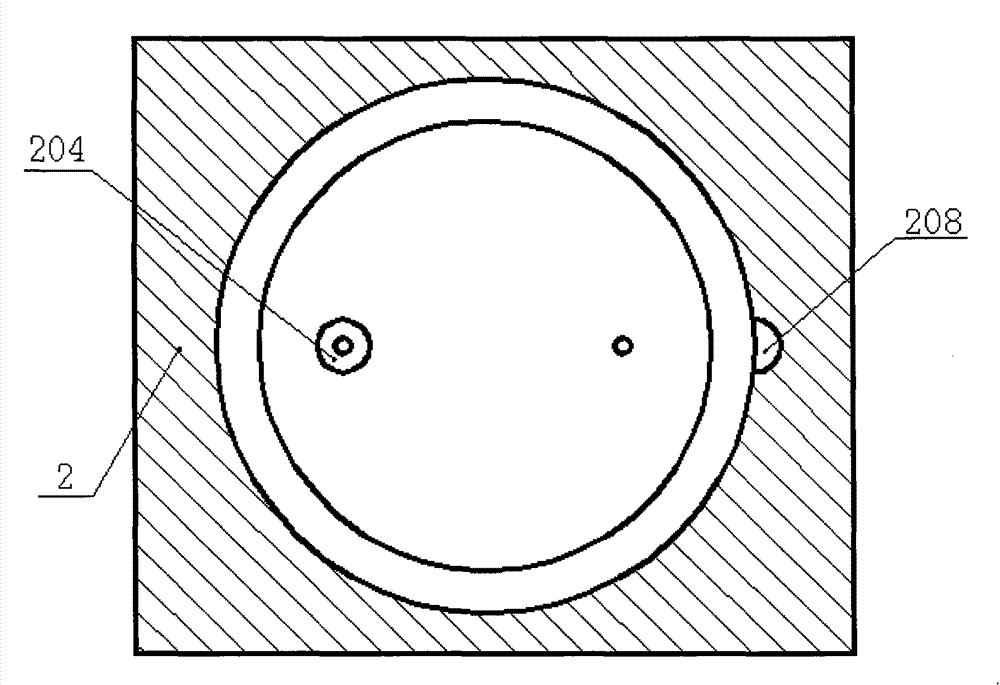

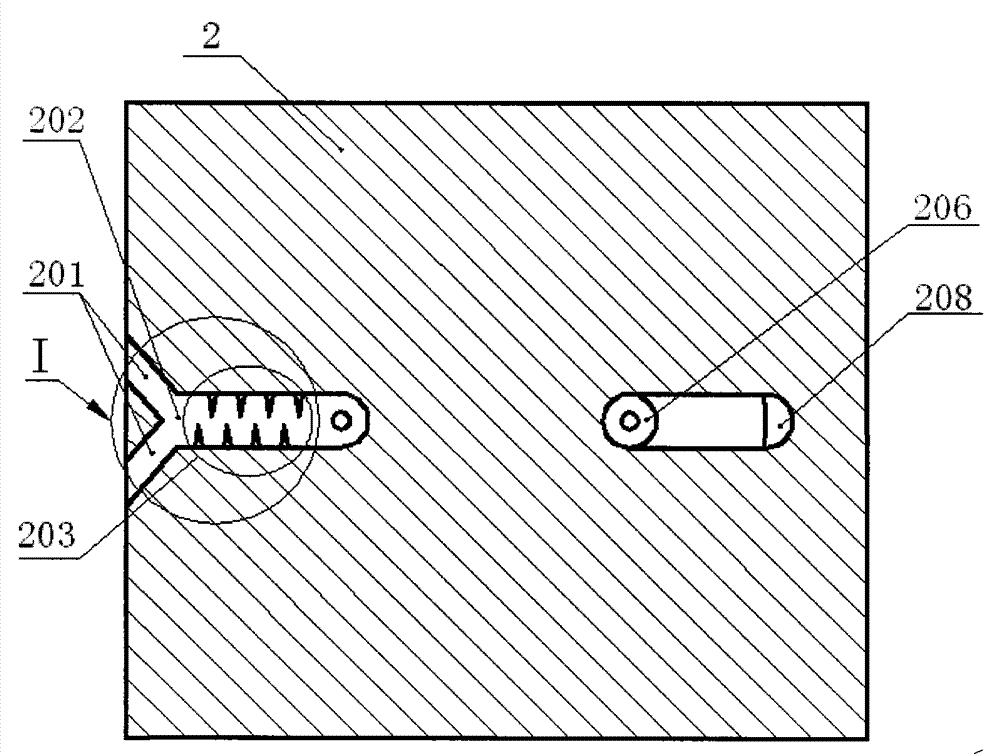

[0022] refer to figure 1 , figure 2 and image 3The lower side of the base body 2 is provided with two inlets 201, an inlet cavity 202 and a horizontal series channel 207, the two inlets 201 communicate with the inlet cavity 202; the two side walls of the inlet cavity 202 are provided with passive mixing Unit 203; the upper part of the inlet cavity 202 is provided with a conical inlet port 204 communicating with it, and the upper part of the horizontal series channel 207 is provided with a conical port 206 at the serial end communicating therewith; the upper side of the base body 2 In the middle, there are cylindrical upper pump chambers 209 and lower pump chambers 205 with different diameters from top to bottom (the diameter of the upper pump chamber 209 is greater than the diameter of the lower pump chamber 205); the upper pump chamber 209 and the lower pump chamber The cavity 205 is separated by a circular piezoelectric vibrator 4; the circular piezoelectric vibrator 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com