Device for determining density continuous distribution of uniform-thickness transparent high polymer product

A technology of high polymer products and measuring devices, which is applied in the direction of measuring devices, specific gravity measurement, and analytical materials, etc., can solve the problems of physical and chemical pollution, unsuitable density measurement, low accuracy, etc., and achieve the effect of high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

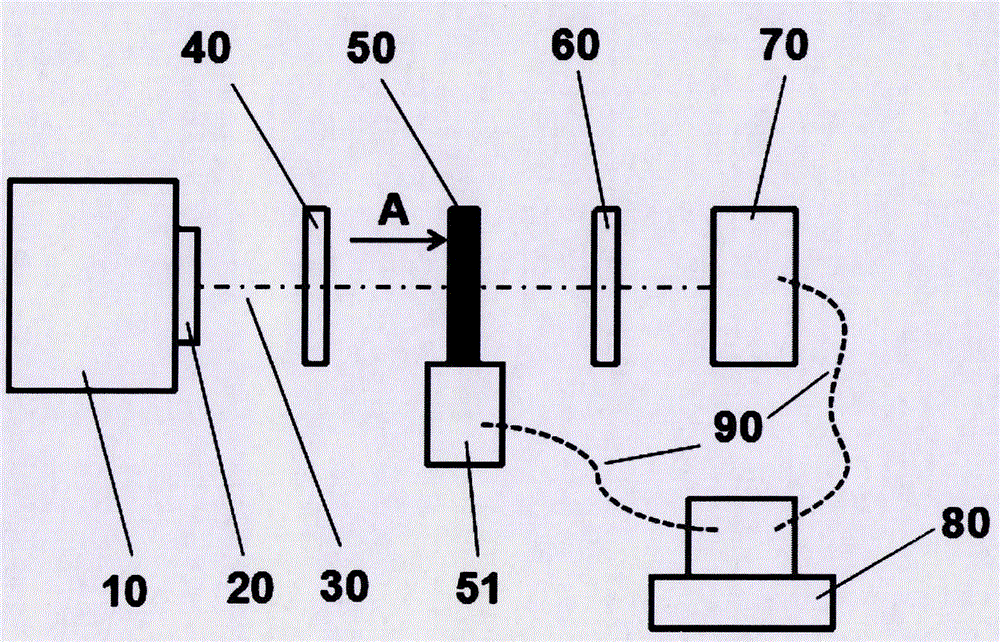

Method used

Image

Examples

Embodiment 1

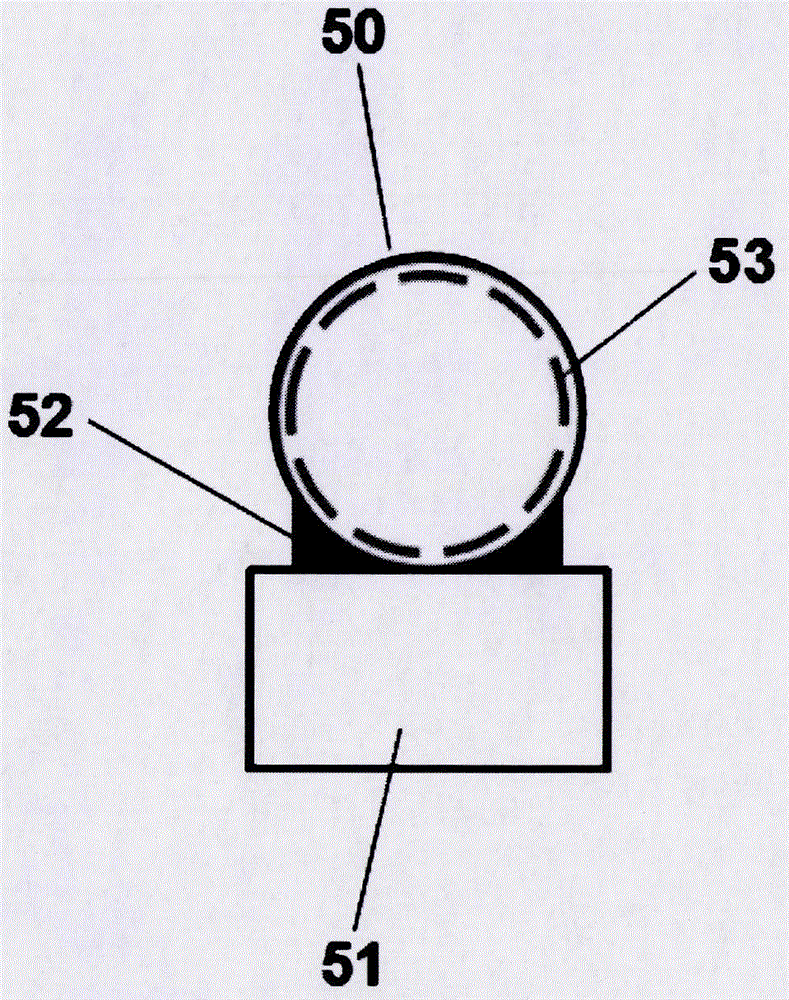

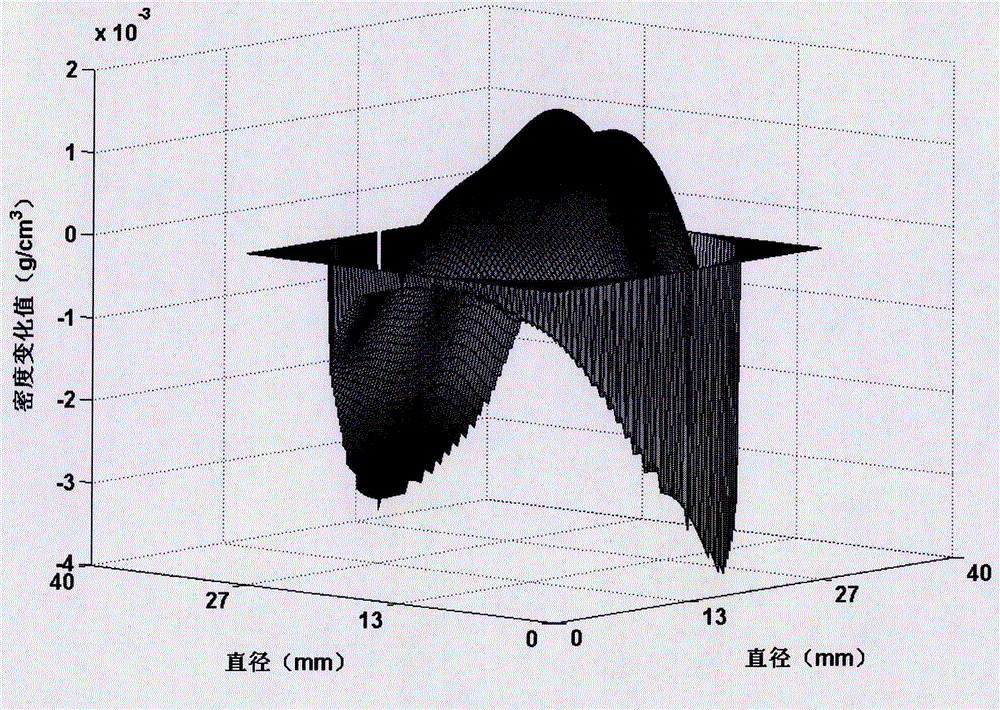

[0030] refer to figure 2 , in this embodiment, the laser source generated by the laser generator 10 forms a circular laser beam after passing through the laser beam shape frame 20, and the shape of the equal-thickness transparent polymer product 50 to be measured is circular, and the circular laser beam forms The diameter of the circular laser spot 53 is slightly smaller than the diameter of the equal-thickness transparent polymer product 50 to be measured, and the measurement can be completed without adjusting the position of the sample position adjustment system 51 at this time. The material of getting the equal thickness transparent high polymer product 50 to be measured is polymethyl methacrylate (PMMA), and its diameter is 40mm, thickness is 0.45mm, refractive index is 1.489, and density is 1.172g / cm 3 . After being measured by a density continuous distribution measuring device of a transparent high polymer product of equal thickness according to the present invention, ...

Embodiment 2

[0032] refer to Figure 4 , in this embodiment, the laser source generated by the laser generator 10 forms a square laser beam after passing through the laser beam shape frame 20, and the shape of the equal-thickness transparent polymer product 50 to be measured is a square shape, and the square laser spot formed by the square laser beam The side length of 53 is much smaller than the side length of the equal-thickness transparent high polymer product 50 to be measured. At this time, the position of the sample position adjustment system 51 needs to be adjusted along the x and y directions to complete the measurement.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com