Preparation method of micro-channel vertical-growth TiO2-clading ZnO nano rod array

A nanorod array and vertical growth technology, which is applied in the intersection of nanotechnology and microfluidic technology, can solve the problems of reducing the solid-liquid contact area between the catalyst and the reaction liquid, the separation and regeneration of nanocatalysts, and the widespread use of nanocatalysts. The effect of surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

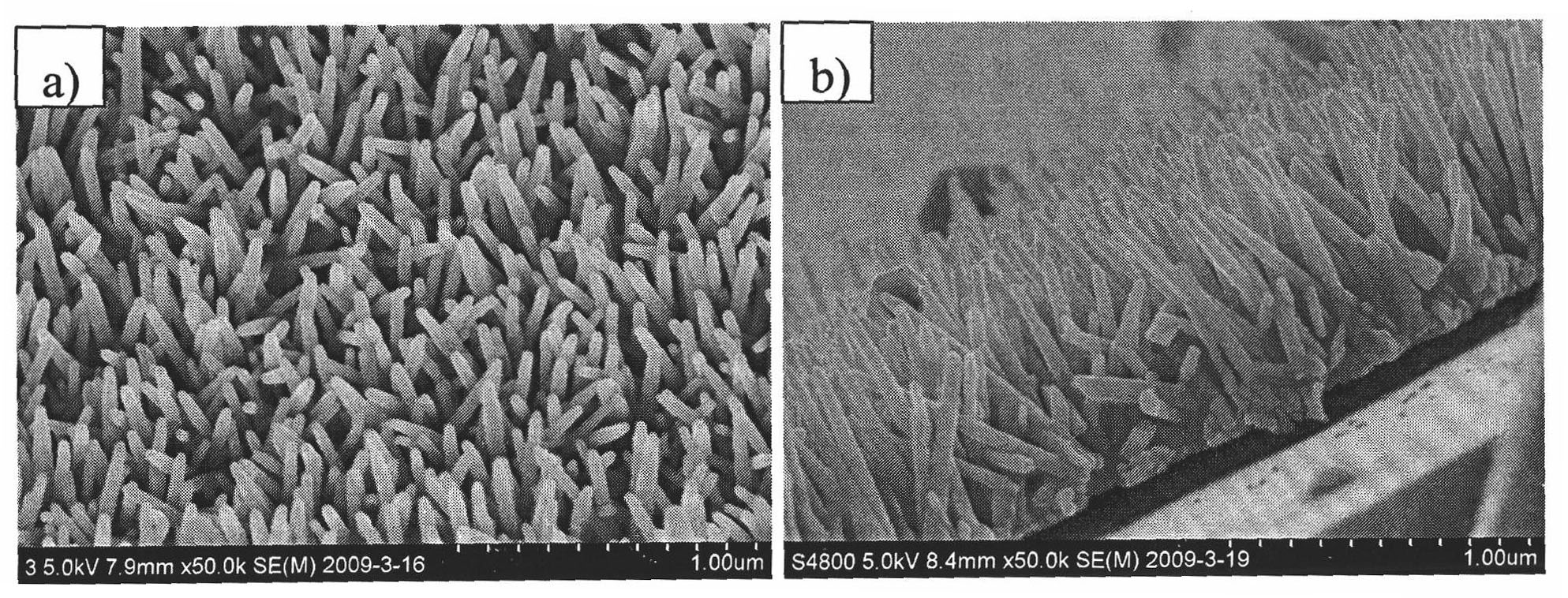

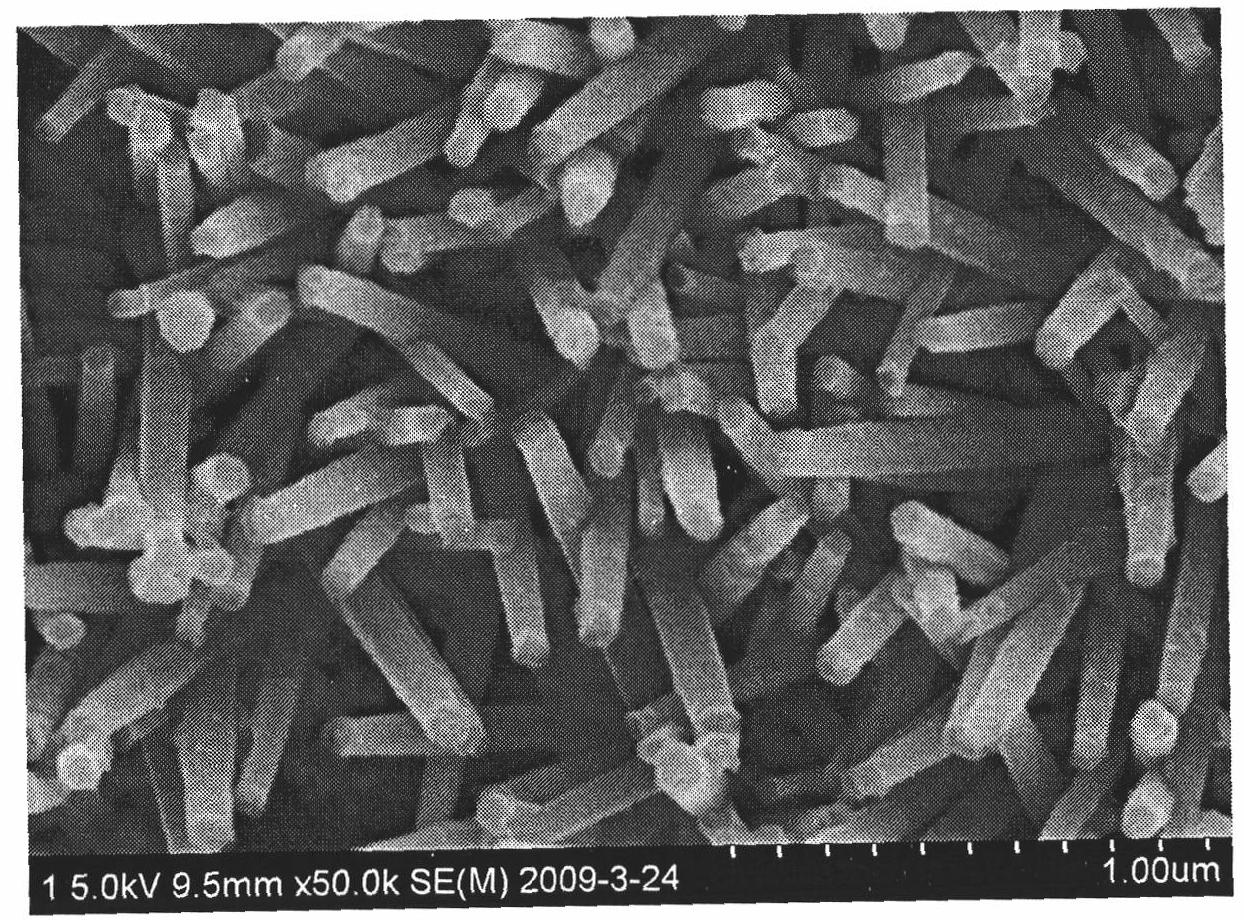

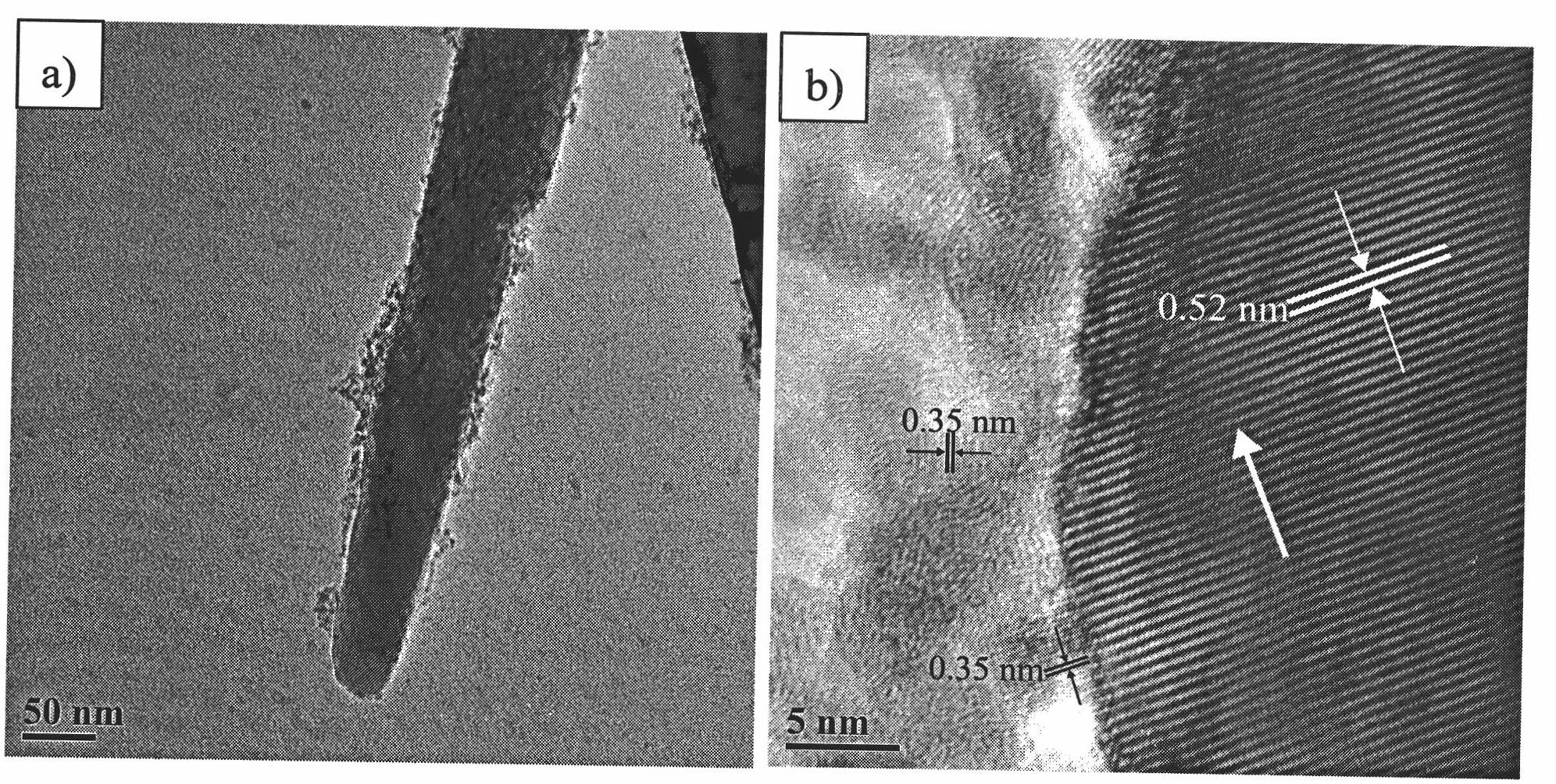

[0032] Preparation of Lotion I (V 浓硫酸 :V 双氧水 :V 蒸馏水 =4:1:20) and lotion II (V 氨水 :V 双氧水 :V 蒸馏水 =1:4:20). Soak the microchannel in lotion I at 110°C for 10 minutes, rinse it with deionized water, then soak the microchannel in lotion II at 70°C for 10 minutes, rinse it with deionized water, and dry it for later use. Prepare 0.01M ethanol solution of zinc acetate dihydrate, 0.04M ethanol solution of sodium hydroxide, 0.05M solution of zinc nitrate hexahydrate, and 0.05M solution of hexamethylenetetramine. Inhale the ethanol solution of zinc acetate dihydrate and the ethanol solution of sodium hydroxide into two 10mL syringes respectively, set the push speed of the microinjection pump at 25 μL / min, and deliver them simultaneously to the microchannel pre-placed in a 60°C oven. After the microchannel is filled, the transportation is stopped, and after 2 hours of reaction, the temperature of the oven is raised to 150°C for 1 hour for annealing. The microchannel is washed succe...

Embodiment 2

[0034] Preparation of Lotion I (V 浓硫酸 :V 双氧水 :V 蒸馏水 =4:1:20) and lotion II (V 氨水 :V 双氧水 :V 蒸馏水 =1:4:20). Soak the microchannel in lotion I at 110°C for 30 minutes, rinse with deionized water, then soak the microchannel in lotion II at 60°C for 30 minutes, rinse with deionized water, and dry for later use. Prepare 0.01M ethanol solution of zinc acetate dihydrate, 0.04M ethanol solution of sodium hydroxide, 0.025M solution of zinc nitrate hexahydrate, and 0.025M solution of hexamethylenetetramine. Inhale the ethanol solution of zinc acetate dihydrate and the ethanol solution of sodium hydroxide into two 10mL syringes respectively, set the push speed of the microinjection pump at 50 μL / min, and deliver them simultaneously to the microchannel pre-placed in an oven at 30°C. After the microchannel is filled, the transport is stopped, and after 1 hour of reaction, the temperature of the oven is raised to 180°C for 1 hour of annealing. The microchannel is washed successively wi...

Embodiment 3

[0036] Preparation of Lotion I (V 浓硫酸 :V 双氧水 :V 蒸馏水 =4:1:20) and lotion II (V 氨水 :V 双氧水 :V 蒸馏水 =1:4:20). Soak the microchannel in lotion I at 130°C for 10 minutes, rinse it with deionized water, then soak the microchannel in lotion II at 80°C for 10 minutes, rinse it with deionized water, and dry it for later use. Prepare 0.001M ethanol solution of zinc acetate dihydrate, 0.004M ethanol solution of sodium hydroxide, 1M solution of zinc nitrate hexahydrate, and 1M solution of hexamethylenetetramine. Inhale the ethanol solution of zinc acetate dihydrate and the ethanol solution of sodium hydroxide into two 10mL syringes respectively, set the push speed of the microinjection pump to 10 μL / min, and deliver them simultaneously to the microchannel pre-placed in an oven at 80°C. After the microchannel is filled, the transportation is stopped, and after 2 hours of reaction, the temperature of the oven is raised to 150°C for 2 hours for annealing. The microchannel is washed succ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com