Micro needle chip and preparation method thereof

A chip and microneedle technology, applied in the direction of microneedles, needles, and other household appliances, can solve the problems of high industrialization cost, complicated preparation process, and large energy consumption, and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] A method for preparing a microneedle chip, comprising the following steps:

[0077] 1. Male mold preparation.

[0078] Using MEMS (Micro-Electro-Mechanical System) technology, brass is used as the raw material to process the positive mold with a conical needle model on the surface.

[0079] In addition to brass, the positive mold is also made of at least one of stainless steel, aluminum, titanium alloy, nickel, palladium, silicon and silicon dioxide. It only needs to be made of hard material, which can cooperate with the fluid female mold liquid to prepare a female mold with a better cavity shape.

[0080] The male mold can also be prepared by ion etching, laser cutting, chemical etching, X-ray lithography MEMS, or ultraviolet lithography MEMS, etc., only need to prepare the male mold with precise shape .

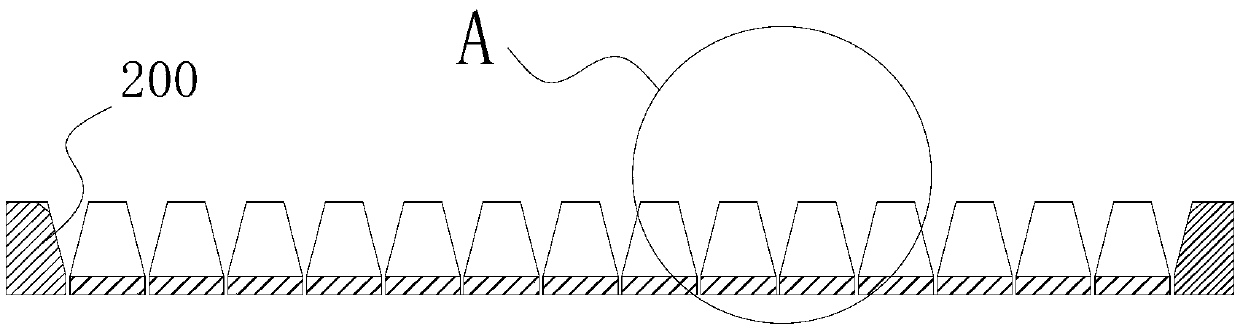

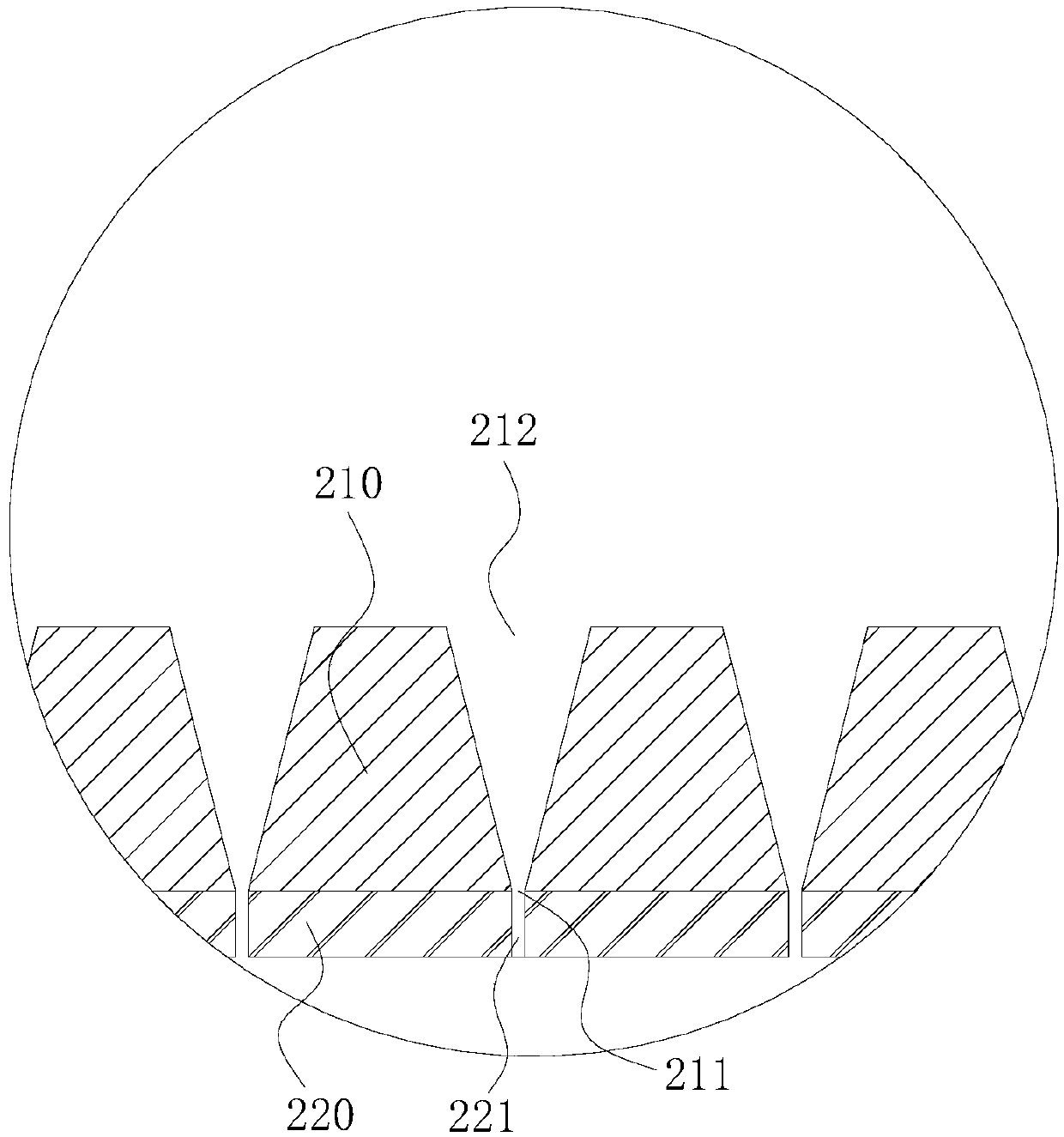

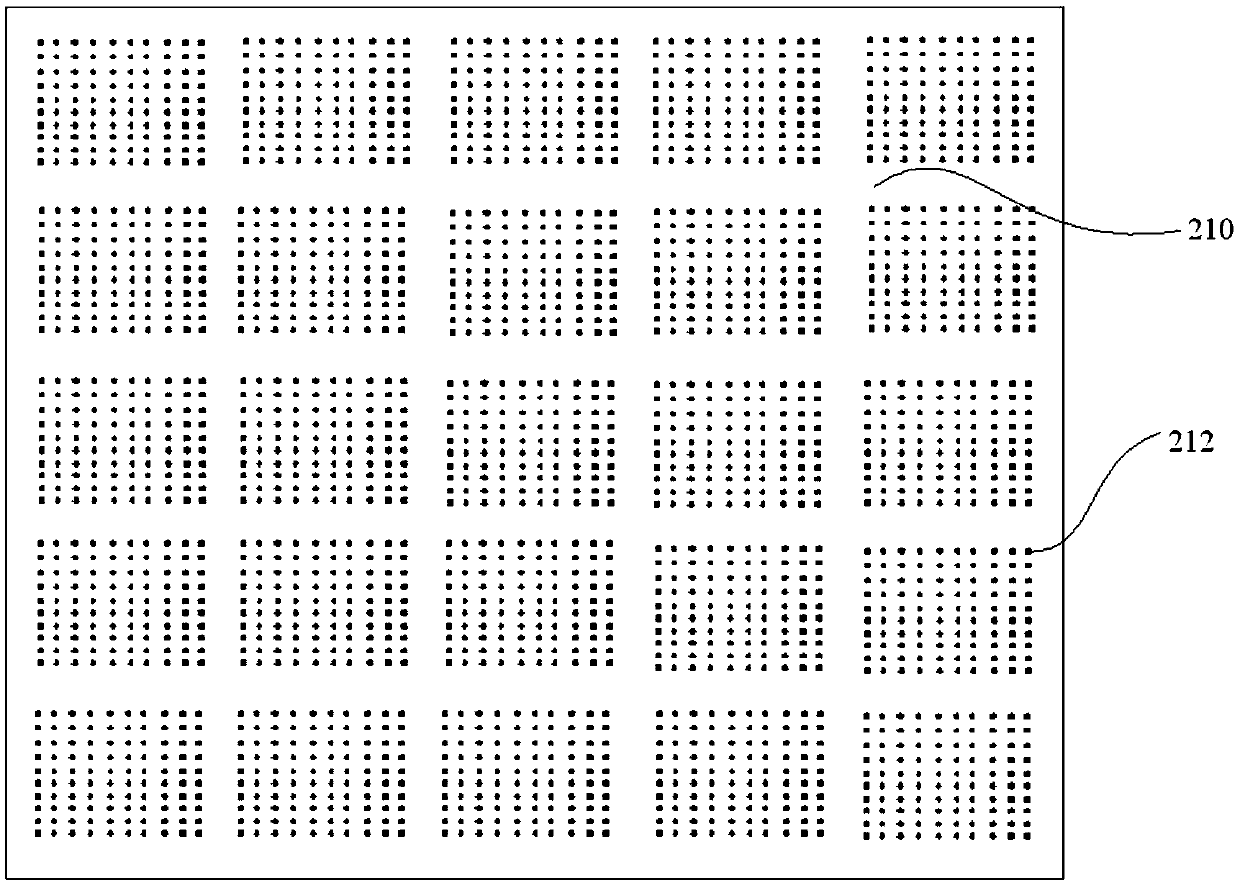

[0081] Such as Figure 6 As shown, the male mold is provided with 10×10 rows (100 pieces) and a microneedle chip needle model array with a height of 550 μm. In t...

Embodiment 2

[0100] A method for preparing a microneedle chip, comprising the following steps:

[0101] 1. Male mold preparation.

[0102] Using MEMS (micro-electro-mechanical system) technology, brass is used as raw material to process a male mold with a conical needle model on the surface. The male mold is equipped with 10×10 rows (100 pieces) of microneedles with a height of 950 μm. Chip needle model array, in the microneedle chip needle model array, the diameter of the bottom of the needle model is 200 μm, and the needle spacing is 300 μm.

[0103] Second, negative mold preparation.

[0104] Take the pre-mixed and degassed Sylgard184 silicone elastomer as the liquid female mold solution, inject it into the above-mentioned male mold, place the male mold on a horizontal plane, and make the liquid female mold solution submerge the height of the needle tip of the male mold. 200μm, placed at 60°C for 4 hours, cured, demolded to form a female mold of 5.0cm×5.0cm, and then drill holes on th...

Embodiment 3

[0121] A method for preparing a microneedle chip, comprising the following steps:

[0122] 1. Male mold preparation.

[0123] Using MEMS (micro-electro-mechanical system) technology, brass is used as raw material to process a male mold with a conical needle model on the surface. The male mold is equipped with 10×20 rows (100 pieces) of microneedles with a height of 250 μm. Chip needle model array, in the microneedle chip needle model array, the diameter of the bottom of the needle model is 100 μm, and the needle spacing is 100 μm.

[0124] Second, negative mold preparation.

[0125] Take the pre-mixed and degassed SILASTICMDX4-4210 silicone elastomer as the liquid female mold solution, inject it into the above male mold, place the male mold on a horizontal plane, and let the needle tip of the male mold see through the liquid female mold The liquid surface of the solution is placed at room temperature for 24 hours, cured, and demoulded to form a 5.0cm×5.0cm female mold, which...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com