Plate for making wind turbine blades, wind turbine blade spar cap structure and preparation method

A wind turbine blade and cap structure technology, which is applied to mechanical equipment, wind power engines, machines/engines, etc., can solve the problems of reducing the strength of the blade forming structure and increasing the distance between plates, so as to improve the bonding strength between layers and reduce the perfusion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

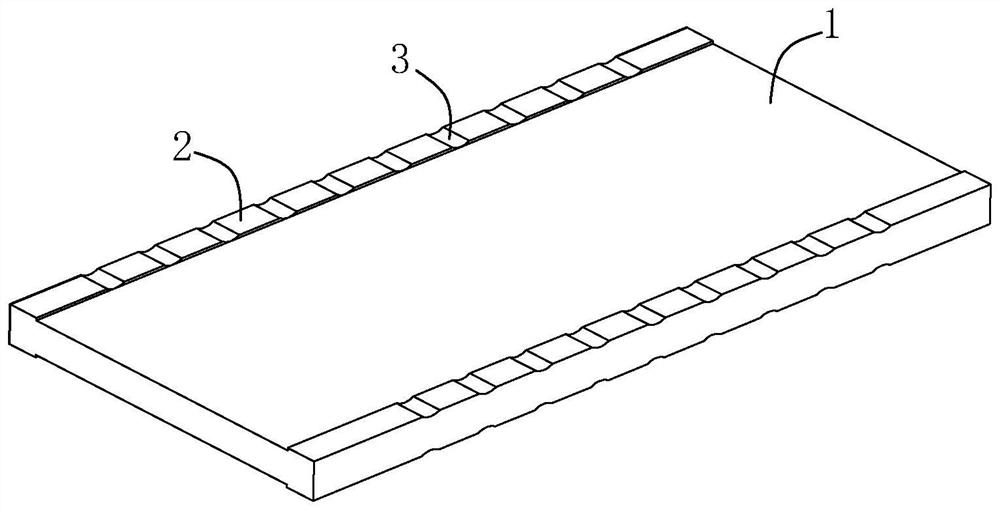

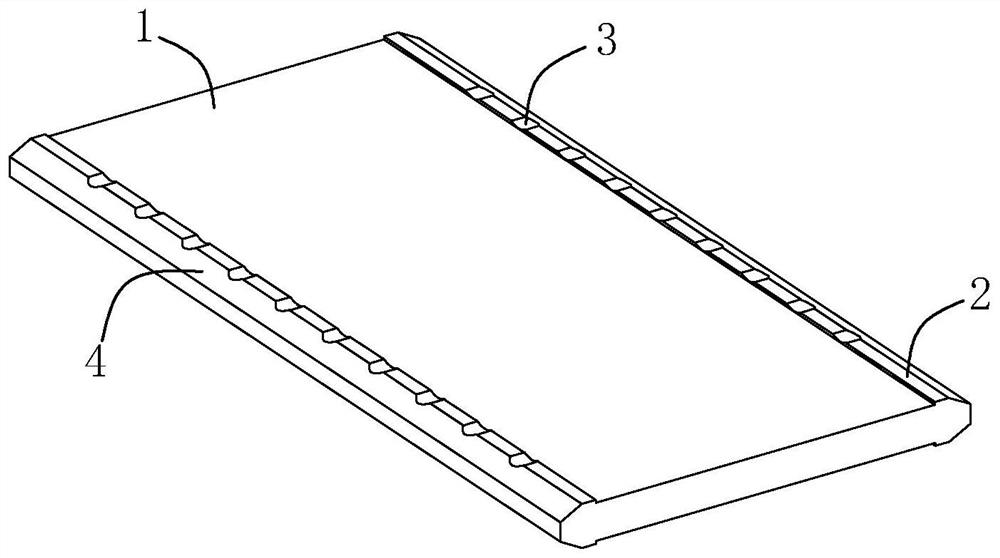

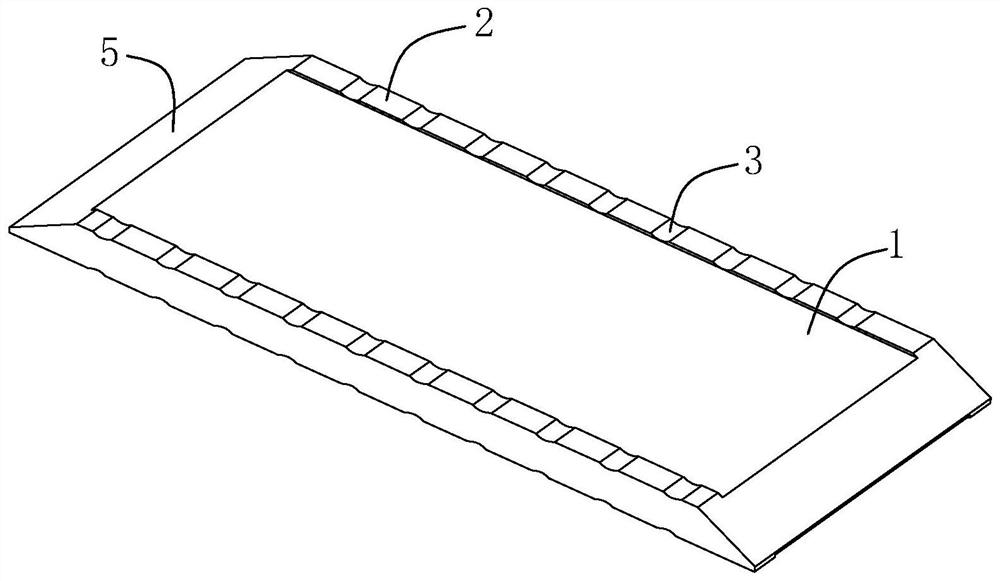

[0053]At present, wind turbine blades are mostly made of stacked carbon fiber plates, and curable materials such as resin are used to cure each plate. When using resin to combine various panels, the uniformity of resin infusion and whether there will be air cavities between the panels will affect the structural strength of the panels.

[0054] In order to facilitate the flow of resin between the plates, in the prior art, it is not uncommon to directly make grooves on the surface of the plates. Through grinding, a coherent flow groove is formed on the surface of the plates. Although it can promote the flow of resin, grinding and grooving The fiber continuity on the surface of the board is also greatly damaged, and the strength of the surface structure of the board is reduced. The purpose of the present invention is to provide a plate for wind turbine blades, which eliminates or reduces the above-mentioned problems through a special structural arrangement.

[0055] The present ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com