Cold-contraction type electric fluorosilicone sleeve and application thereof

A bushing and fluorosilicone technology, applied in the direction of cable joints, etc., can solve the problems of physical and mechanical properties decline, low leakage current intensity, poor storage stability, etc., and achieve excellent mechanical properties, low resilience, and small permanent deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

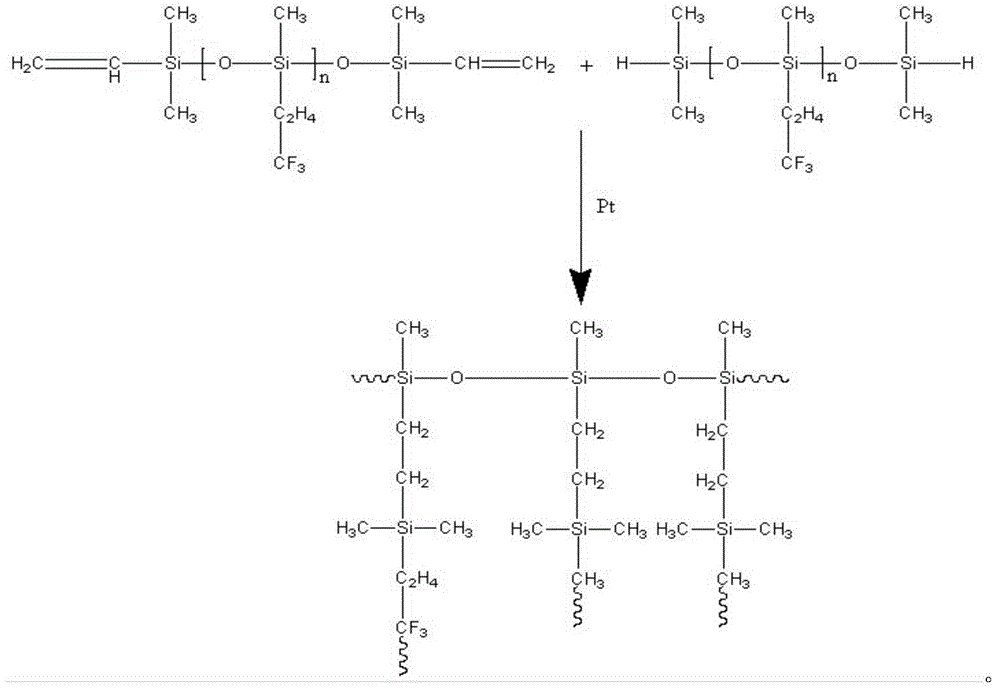

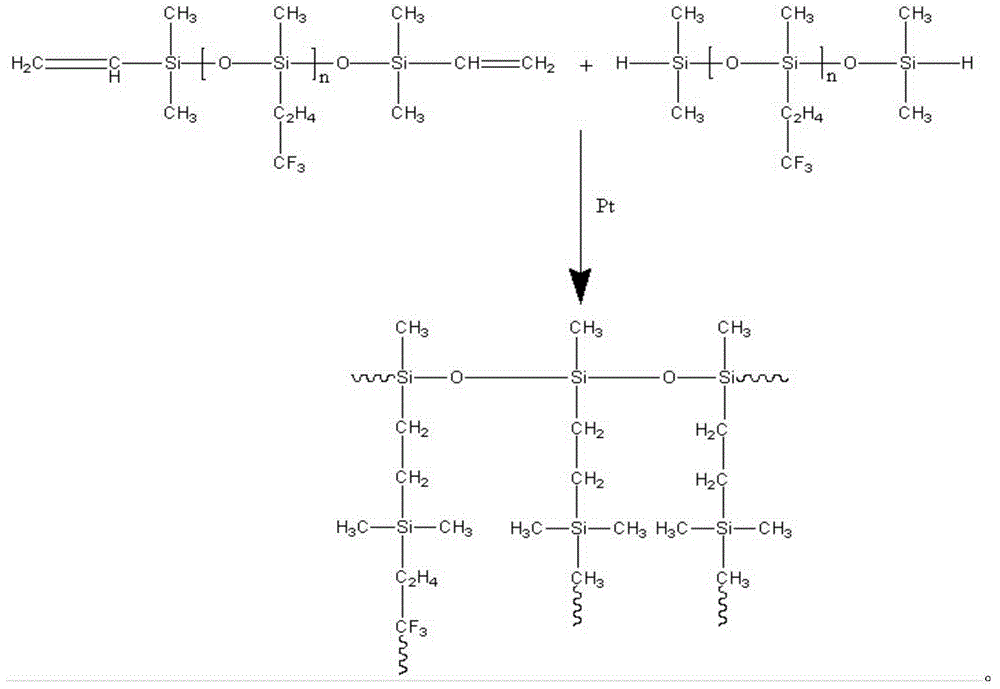

Method used

Image

Examples

Embodiment 1

[0037] Mix 60 parts of organopolyfluorosiloxane, 40 parts of hydrophobized fumed silica, and 6 parts of additives in a mixer, heat up to 140-150°C, and heat-preserve fumed silica for 6 hours. , then evacuate for 0.5h to remove the additives, heat up to 170°C for 3h, control the temperature higher than 175°C, and then evacuate for 1h, after stirring and cooling, the roller speed ratio of the mill is 2.0, and the distance between the rollers is 5mm. Water cooling method, when the temperature is controlled at 20°C, add 30 parts of organic hydrogen-containing polyfluorosiloxane and 0.3 parts of 6000PPm noble metal catalyst and mix evenly, then extrude at 450°C, extrusion speed 30rpm, vulcanization traction temperature is 200 ℃, using an extrusion mold, the concentricity deviation is not greater than 0.06mm, the continuous extrusion sleeve molding size is: inner diameter 6mm, wall thickness 0.5mm, tolerance plus or minus 0.08mm, that is, a cold shrinkable power fluorosilicone sleeve...

Embodiment 2

[0040] Mix 55 parts of organopolyfluorosiloxane, 45 parts of hydrophobized fumed silica, and 7 parts of additives in a mixer, heat up to 140-150°C, and heat-preserve fumed silica for 6 hours , then evacuate for 0.5h to remove the additives, heat up to 170°C for 3h, control the temperature higher than 175°C, and then evacuate for 1h, after stirring and cooling, the roller speed ratio of the mill is 2.0, and the distance between the rollers is 5mm. Water cooling method, when the temperature is controlled at 20°C, add 35 parts of organic hydrogen-containing polyfluorosiloxane and 0.3 parts of 6000PPm precious metal catalyst and mix evenly, then extrude at 480°C, extrusion speed 28rpm, vulcanization traction temperature 210 ℃, using an extrusion mold, the concentricity deviation is not greater than 0.06mm, the continuous extrusion sleeve molding size is: inner diameter 12mm, wall thickness 1.5mm, tolerance plus or minus 0.09mm, that is, a cold shrinkable power fluorosilicone sleeve...

Embodiment 3

[0043] Mix 58 parts of organopolyfluorosiloxane, 42 parts of hydrophobized fumed silica, and 6 parts of additives in a mixer, heat up to 140-150°C, and heat-preserve fumed silica for 6 hours , then evacuate for 0.5h to remove the additives, heat up to 170°C for 3h, control the temperature higher than 175°C, and then evacuate for 1h, after stirring and cooling, the roller speed ratio of the mill is 2.0, and the distance between the rollers is 5mm. Water cooling method, when the temperature is controlled at 20°C, add 37 parts of organic hydrogen-containing polyfluorosiloxane and 0.3 parts of 6000PPm noble metal catalyst and mix evenly, then extrude at 500°C, extrusion speed 25rpm, vulcanization traction temperature 230 ℃, using an extrusion mold, the concentricity deviation is not greater than 0.06mm, the continuous extrusion sleeve molding size is: inner diameter 15mm, wall thickness 2.0mm, tolerance plus or minus 0.12mm, that is, a cold shrinkable power fluorosilicone sleeve ....

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com