Fluorinated silicone rubber dielectric elastomer composite material and preparation method thereof

A technology of dielectric elastomer and fluorosilicone rubber is applied in the field of fluorosilicone rubber dielectric elastomer composite material and its preparation, which can solve the problems of increasing Young's modulus, increasing material defects, increasing material brittleness and the like, and achieves electric shock. The effect of increased penetration strength, large electro-deformation, and increased dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

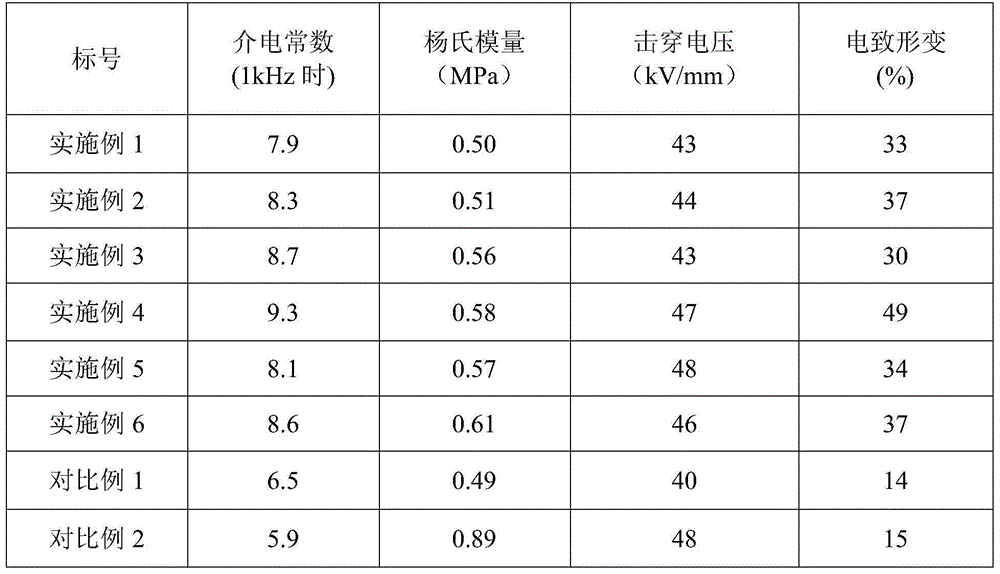

Examples

Embodiment 1

[0024] Example 1: Using poly(3,3,3-trifluoropropylmethyl) silicone rubber as a matrix, and using titanium dioxide as a filler, (1) 100 parts by mass of fluorosilicone rubber is masticated at room temperature on an open mill, and then Gradually add 0.2 parts by mass of bis-2,5 (2,5-dimethyl-2,5-di-tert-butylperoxyhexane), knead with a knife, make a triangle bag, make it evenly mixed, and then gradually add 5 parts by mass of rutile titanium dioxide with a particle diameter of 30nm, kneaded uniformly, and released into sheets. (2) After mixing and parking for 7 hours, carry out a stage of vulcanization: set the pressure at 10 MPa and the temperature at 170° C. for 10 minutes on a 25-ton electric heating plate vulcanizer produced by Shanghai Rubber Machinery Manufacturing. (3) After one-stage vulcanization, place it in a blast oven at 200°C for 4 hours for two-stage vulcanization. A cross-linked fluorosilicone rubber / titanium dioxide dielectric elastomer is obtained. (4) Take a...

Embodiment 2

[0025] Embodiment 2: The preparation method is the same as that of Embodiment 1, except that the parts of titanium dioxide are 10 parts by mass. The test results are shown in Table 1.

Embodiment 3

[0026] Example 3: Using poly(3,3,3-trifluoropropylmethyl) silicone rubber as a matrix, using titanium dioxide as a filler, (1) masticating 100 parts by mass of fluorosilicone rubber at room temperature on an open mill, and then Gradually add 0.5 parts by mass of DCP, knead with a knife, pack into triangles to make it evenly mixed, then gradually add 10 parts by mass of rutile titanium dioxide with a particle size of 30 nm, mix evenly, and produce tablets. (2) After mixing and parking for 7 hours, carry out a stage of vulcanization: set the pressure on a 25-ton electric heating plate vulcanizer manufactured by Shanghai Rubber Machinery to 15 MPa. The temperature is 160°C for 20 minutes of vulcanization. (3) After one-stage vulcanization, place it in a blast oven at 180°C for 5 hours for two-stage vulcanization. A cross-linked fluorosilicone rubber / titanium dioxide dielectric elastomer is obtained. (4) Take a dielectric elastomer electrode test piece with a thickness of 1 mm a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com