Preparation method for germanium substrate and La-based high-dielectric constant gate dielectric material

A high dielectric constant, gate dielectric technology, used in circuits, electrical components, semiconductor/solid-state device manufacturing, etc. The effect of desorption and volatilization, improvement of anti-radiation performance, and improvement of surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

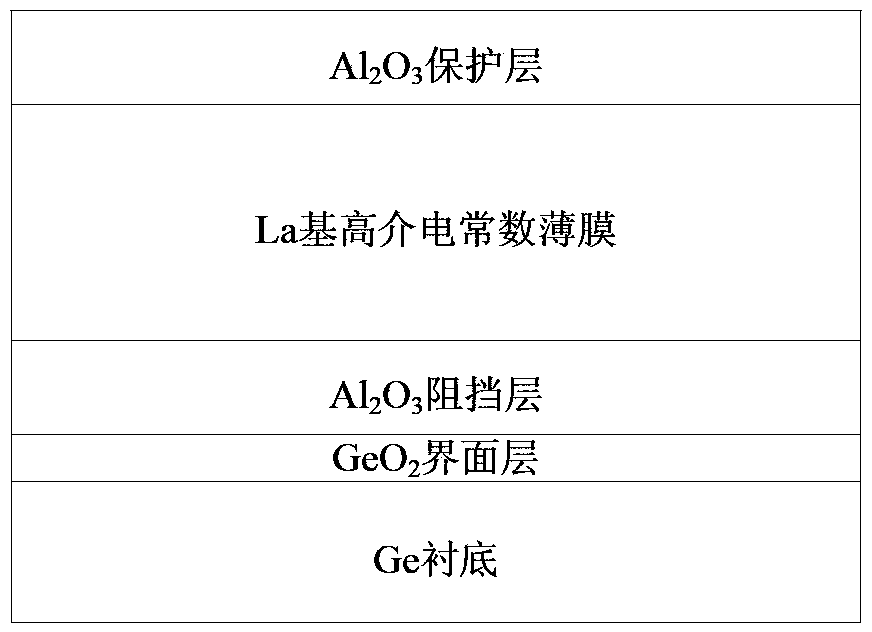

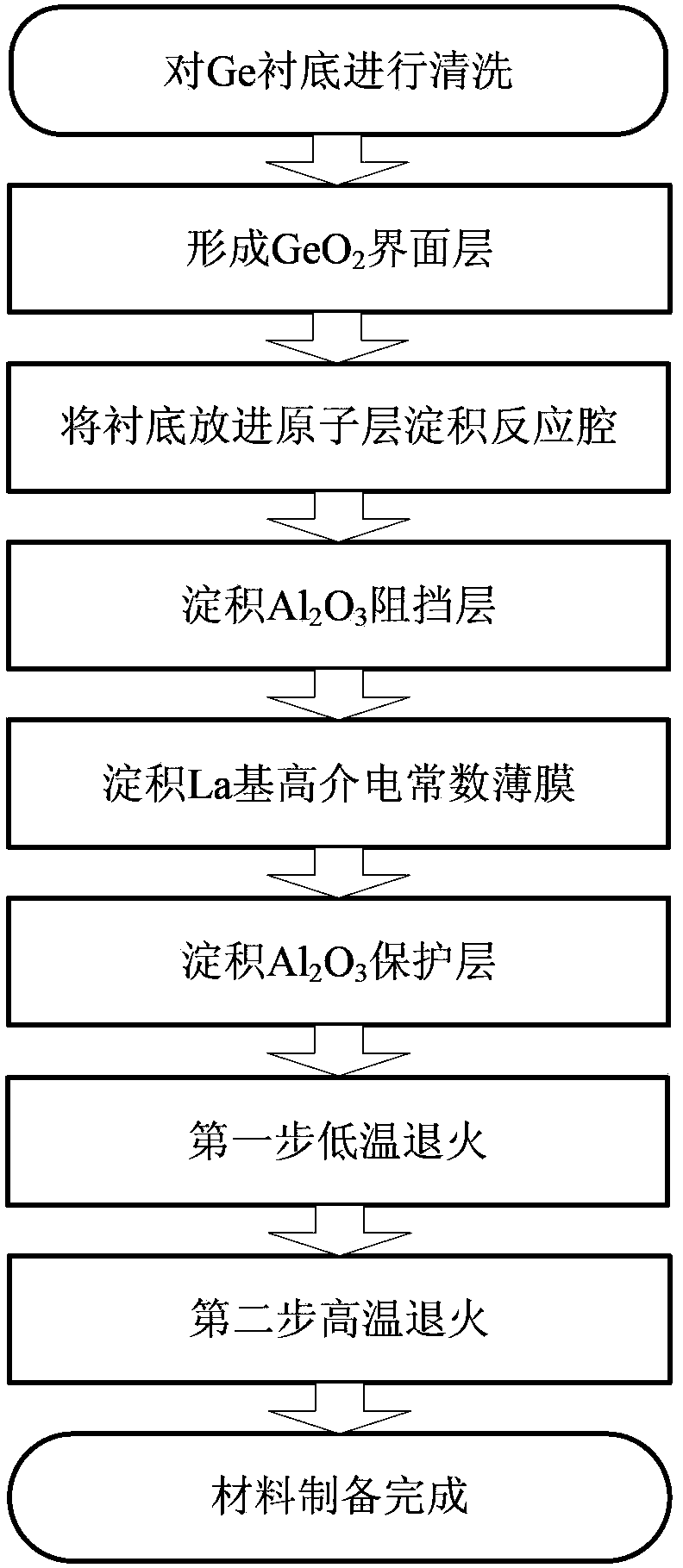

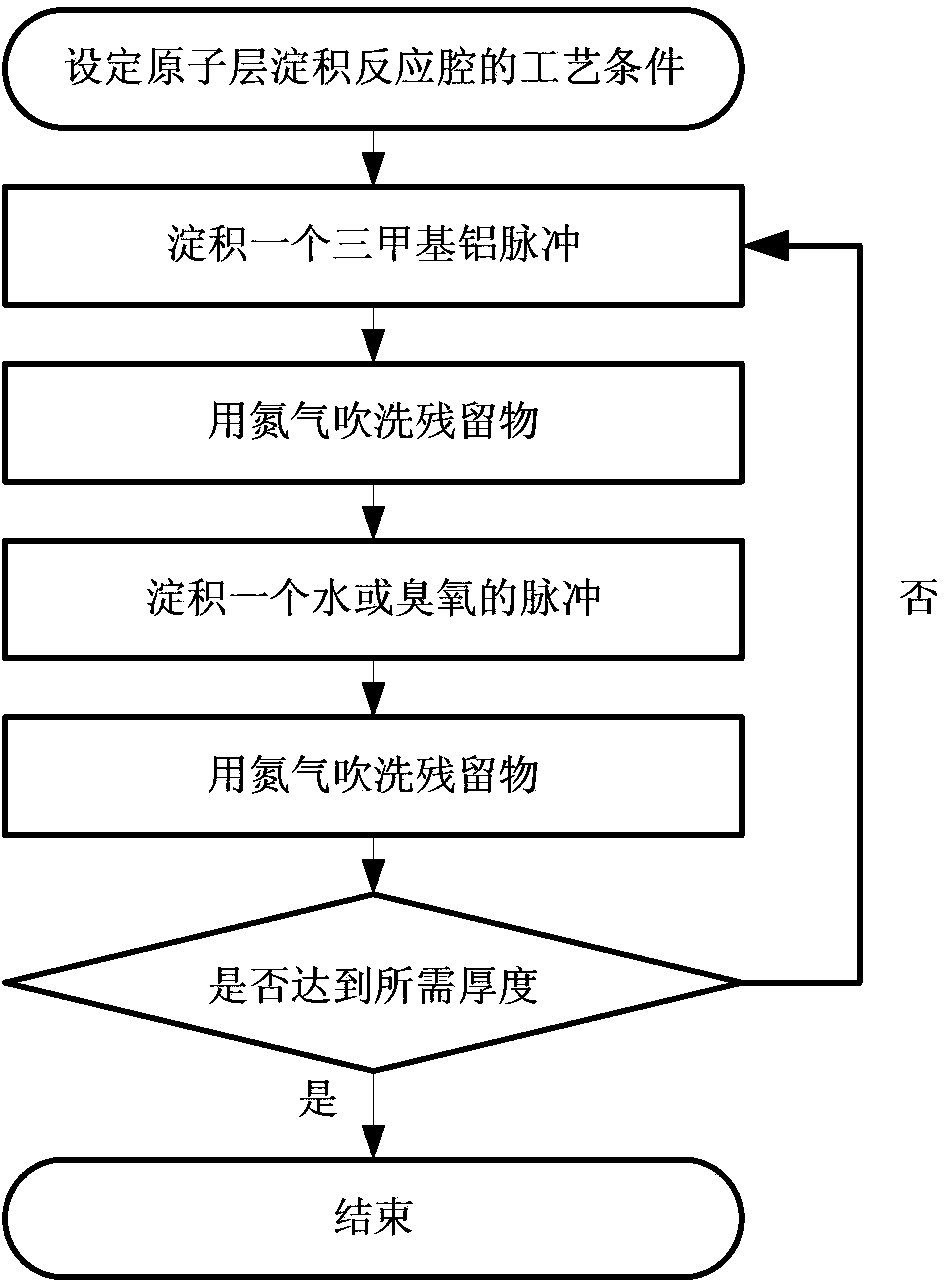

[0056] Example 1, preparation of Al 2 O 3 \La 2 O 3 \Al 2 O 3 \GeO 2 \Ge high dielectric constant gate dielectric material

[0057] Step 1, cleaning the Ge substrate.

[0058] 1a) Clean the Ge substrate in an SC-1 solution heated to 75°C for 10 minutes. The composition of the solution is NH 4 OH, H 2 O 2 and H 2 O, its ratio is 5:1:1, the main effect of this cleaning is to rely on NH 4 Complexation of OH with H 2 O 2 Strong oxidizing ability to remove organic pollutants or attached particles on Ge wafers;

[0059] 1b) Rinse the Ge sheet after cleaning in the SC-1 solution in deionized water for 2 minutes to remove the residual SC-1 solution;

[0060] 1c) Wash the Ge chip in HF solution for 60 seconds, the composition of the solution is HF and H 2 O, whose ratio is 1:400, the main function of this cleaning is to remove the natural oxide layer GeO on the surface of the Ge substrate. 2 ;

[0061] 1d) rinsing the Ge sheet from which the natural oxide layer on the ...

example 2

[0091] Example 2, preparation of Al 2 O 3 \LaAlO 3 \Al 2 O 3 \GeO 2 \Ge high dielectric constant gate dielectric material

[0092] Step 1, cleaning the Ge substrate.

[0093] 1.1) Clean the Ge chip in the SC-1 solution heated to 75°C for 10 minutes. The composition of the solution is NH 4 OH, H 2 O 2 and H 2 O, its ratio is 5:1:1, the main effect of this cleaning is to rely on NH 4 Complexation of OH with H 2 O 2 Strong oxidizing ability to remove organic pollutants or attached particles on Ge wafers;

[0094] 1.2) Rinse the Ge sheet after cleaning in the SC-1 solution in deionized water for 2 minutes to remove the residual SC-1 solution;

[0095] 1.3) Wash the Ge chip in HF solution for 60 seconds, the composition of the solution is HF and H 2 O, whose ratio is 1:400, the main function of this cleaning is to remove the natural oxide layer GeO on the surface of the Ge substrate. 2 ;

[0096] 1.4) Rinse the Ge sheet in deionized water to remove residual HF solut...

example 3

[0128] Example 3, preparation of Al 2 O 3 \HfLaO\Al 2 O 3 \GeO 2 \Ge high dielectric constant gate dielectric material

[0129] Step A, cleaning the Ge substrate.

[0130] Clean the Ge sheet in an SC-1 solution heated to a temperature of 75°C for 10 minutes to remove organic pollutants or attached particles on the Ge sheet. The composition of the solution is NH 4 OH, H 2 O 2 and H 2 O, the ratio is 5:1:1; then rinse the Ge sheet in deionized water for 2 minutes in SC-1 solution to remove residual SC-1 solution; then wash the Ge sheet in HF and H 2 O ratio is 1:400 in the HF solution cleaning 60 seconds, to remove the natural oxide layer of Ge substrate surface; The Ge plate that removes the natural oxide layer of Ge substrate surface is rinsed in deionized water again, to remove residual HF Solution; put the Ge sheet that removes the residual HF solution into deionized water and use ultrasonic cleaning for 5 minutes to remove the adsorption particles on the surface, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com