Power combiner with symmetrically arranged cooling bodies and power combiner arrangement

A power combiner and cooling body technology, which is applied to connection devices, waveguide-type devices, circuits, etc., can solve the problems of power combiner method and method change, large parasitic capacitance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

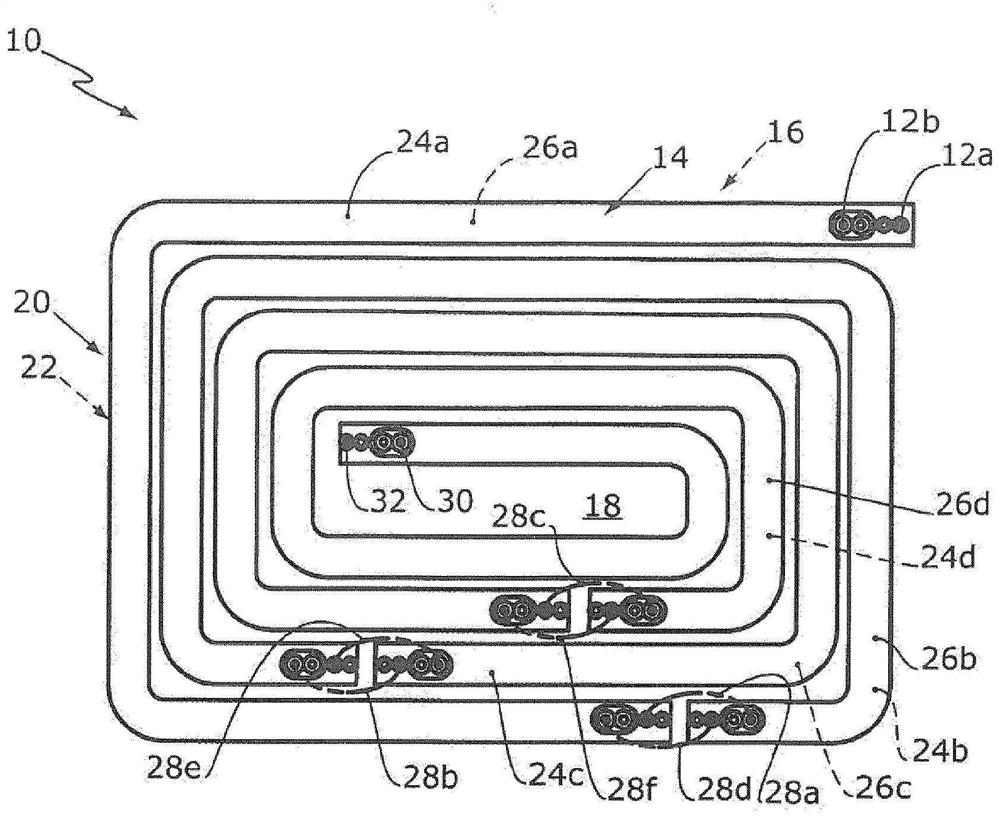

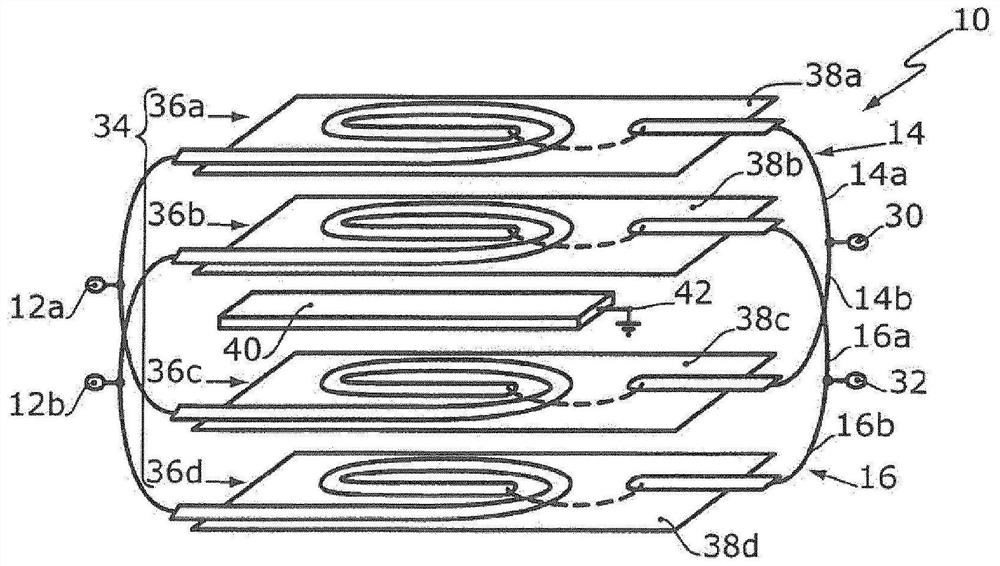

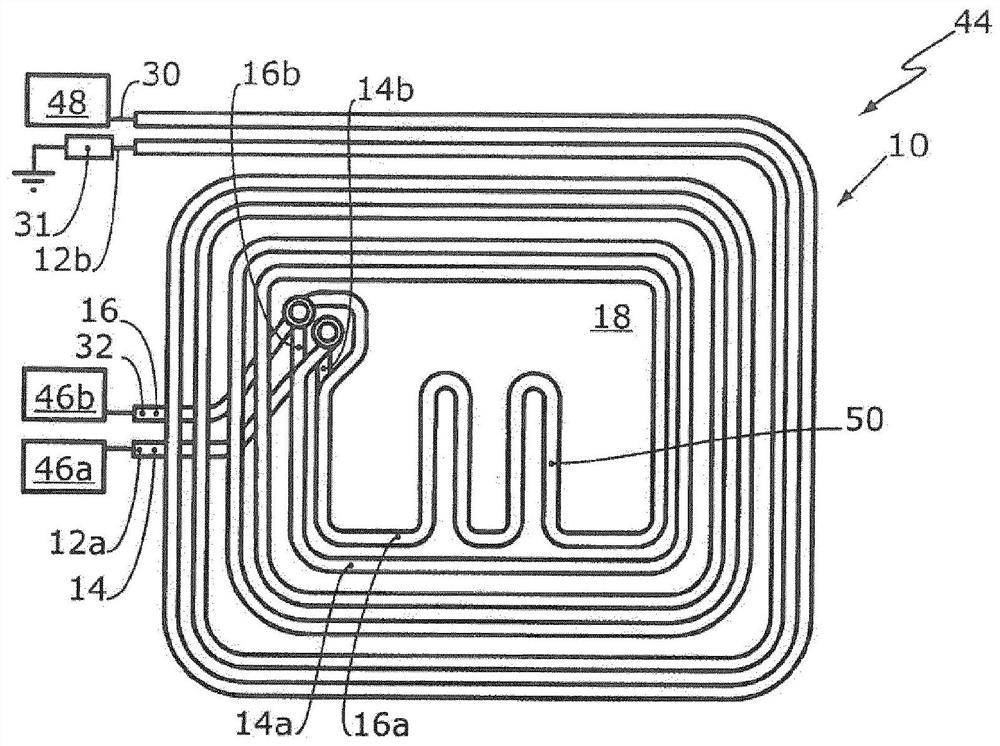

[0065] figure 1 A power combiner 10 is shown. The power combiner 10 has a first input 12 a for a first high-frequency signal and a second input 32 for a second high-frequency signal. The first input 12 a is connected to a first electrical conductor 14 . The second input 32 is connected to the second electrical conductor 16 . The electrical conductors 14, 16 are inductively and capacitively coupled to each other. A dielectric, in particular an electrically insulating substrate 18 , is arranged between the electrical conductors 14 , 16 .

[0066] More precisely, the power combiner 10 is formed in the present case by a circuit board with a dielectric, in particular an insulating substrate 18 , wherein a first capable Conductive layer 20 , on the second planar main side of the dielectric, in particular electrically insulating substrate 18 , is arranged a second electrically conductive layer 22 which extends parallel to the first electrically conductive layer.

[0067] The fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com