Three-layer structure lead zirconate titanate ferroelectric ceramic material and preparation method thereof

A technology of lead zirconate titanate and ferroelectric ceramics, applied in the field of ferroelectric ceramic materials, can solve the problems of reducing the dielectric breakdown strength of materials, reducing material breakdown strength, increasing dielectric loss, etc., and achieving the electrical breakdown of dense ceramics Strength, optimized reliability and safety, effect of high electrical breakdown strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

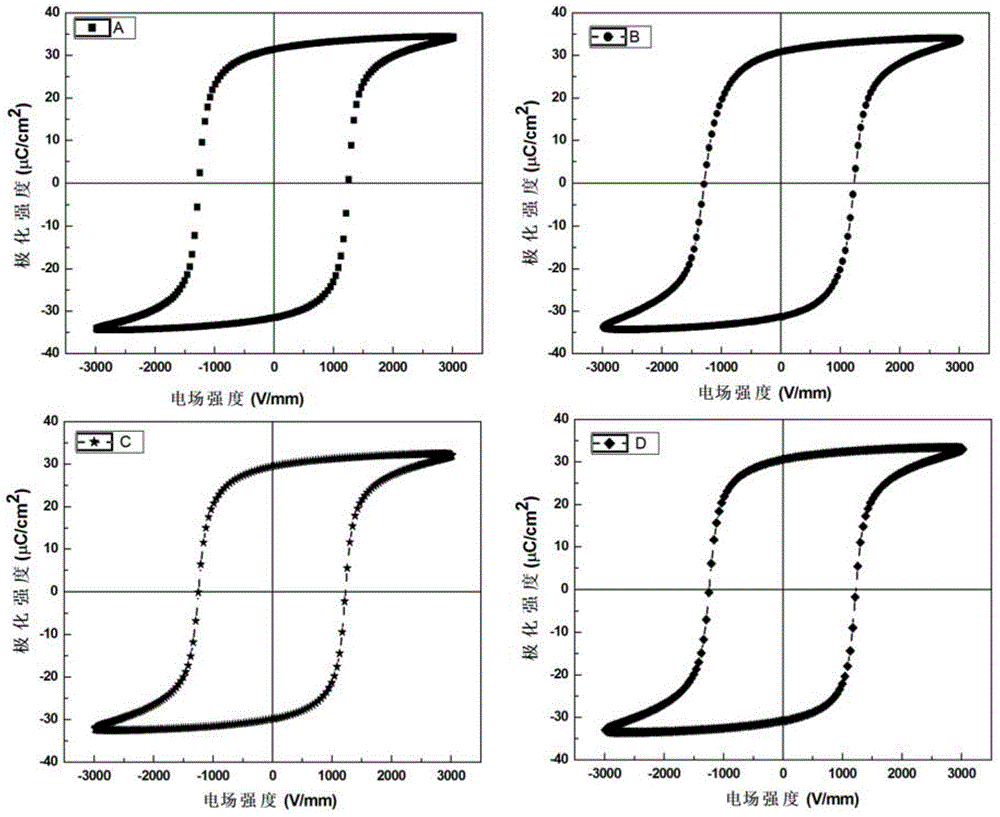

Embodiment 1

[0025] According to PbZr 0.95 Ti 0.05 O 3 The stoichiometric ratio of Pb 3 O 4 , ZrO 2 and TiO 2 Raw materials, mixed powder with wet ball milling, finely ground, and then used solid-phase reaction method to keep the temperature at 800-900 ℃ for 1-3 hours to synthesize Pb (Zr x Ti 1-x )O 3 powder.

[0026] Weigh a certain amount of PbZr 0.95 Ti 0.05 O 3 Powder, add PbZr 0.95 Ti 0.05 O 3 PMMA microspheres with a diameter of 10 μm and 1% by weight of the powder were mixed uniformly, finely ground and dried, and PbZr was added. 0.95 Ti 0.05 O 3 PVA binder with a weight of 5% of the powder, granulated, aged for 24 hours, passed through a 30-mesh sieve for use; in addition, a certain amount of PbZr 0.95 Ti 0.05 O 3 Add PbZr to the powder 0.95 Ti 0.05 O 3 PVA binder of 5% by weight of powder, granulated, aged for 24 hours, passed through a 30-mesh sieve for use.

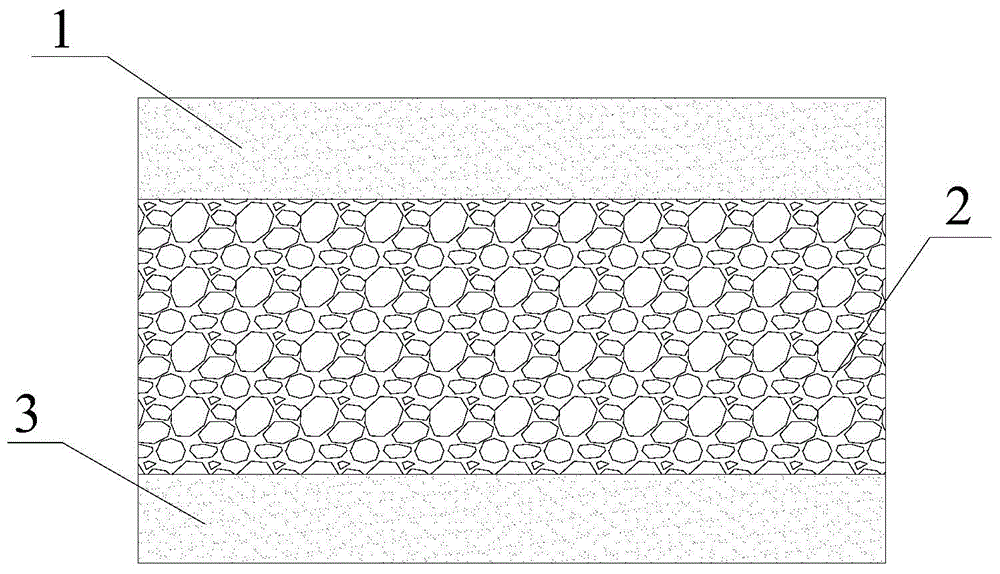

[0027] Add two plexiglass plate diaphragms to the forming mold to separate the mold into three la...

Embodiment 2

[0032] Prepare PbZr as in Example 1 0.95 Ti 0.05 O 3 powder.

[0033] Weigh a certain amount of PbZr 0.95 Ti 0.05 O 3 Powder, add PbZr 0.95 Ti 0.05 O 3 PMMA microspheres with a diameter of 20 μm and 1% by weight of the powder were mixed uniformly, finely ground and dried, and PbZr was added. 0.95 Ti 0.05 O 3 PVA binder with a weight of 5% of the powder, granulated, aged for 24 hours, passed through a 30-mesh sieve for use; in addition, a certain amount of PbZr 0.95 Ti 0.05 O 3 Add PbZr to the powder 0.95 Ti 0.05 O 3 PVA binder of 5% by weight of powder, granulated, aged for 24 hours, passed through a 30-mesh sieve for use.

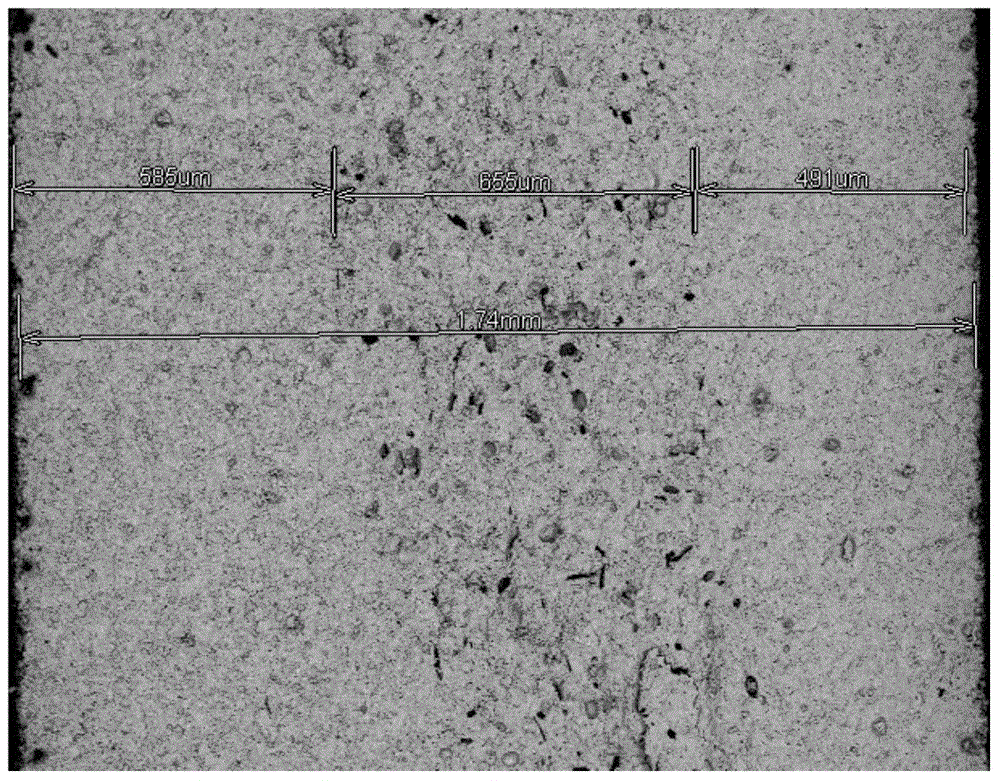

[0034] Add two plexiglass plate diaphragms to the forming mold to separate the mold into three layers of space, and add a pore-forming agent PbZr to the middle layer 0.95 Ti 0.05 O 3 Powder with PbZr without pore former added to both surface layers 0.95 Ti 0.05 O 3 Powder, carefully remove the diaphragm, shape under 200MPa pressure, h...

Embodiment 3

[0036] Prepare PbZr as in Example 1 0.95 Ti 0.05 O 3 powder.

[0037] Weigh a certain amount of PbZr 0.95 Ti 0.05 O 3 Powder, add PbZr 0.95 Ti 0.05 O 3 PMMA microspheres with a diameter of 15-60 μm (D 50 = 30μm), mixed evenly, finely ground, dried, and added with PbZr 0.95 Ti 0.05 O 3 PVA binder with a weight of 5% of the powder, granulated, aged for 24 hours, passed through a 30-mesh sieve for use; in addition, a certain amount of PbZr 0.95 Ti 0.05 O 3 Add PbZr to the powder 0.95 Ti 0.05 O 3 PVA binder of 5% by weight of powder, granulated, aged for 24 hours, passed through a 30-mesh sieve for use.

[0038] Add two plexiglass plate diaphragms to the forming mold to separate the mold into three layers of space, and add a pore-forming agent PbZr to the middle layer 0.95 Ti 0.05 O 3 Powder with PbZr without pore former added to both surface layers 0.95 Ti 0.05 O 3 Powder, carefully remove the diaphragm, shape under 200MPa pressure, hold at 750°C for 2 hour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com