Dry composite foams as electrically insulating materials

A technology of electrical insulating materials and composite foams, which is applied in the direction of insulators, organic insulators, plastic/resin/wax insulators, etc., and can solve problems such as unrealizable and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

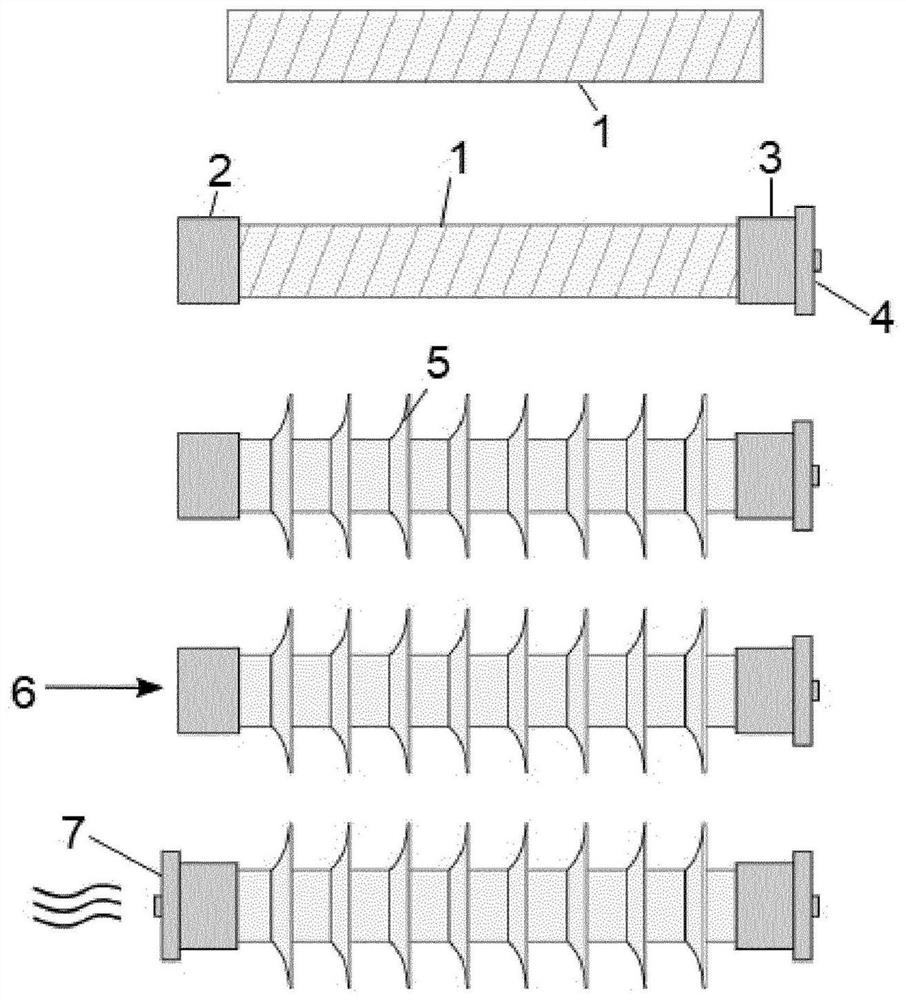

[0078] This example involves the manufacture of dry syntactic foam in an expansion mold.

[0079] Depend on 551 DET 40 d25 expanded micro hollow spheres (34.7% by volume; bulk density 0.0125g / cm 3 )and 551 DU 40 type unexpanded micro hollow spheres (65.4% by volume; bulk density 0.5543g / cm 3 ) composed of 0.2g / cm 3 The mixture of bulk density is expanded at a temperature of 120° C. for a duration of 2 hours in a cylindrical expansion mold made of aluminum with an inner coating of PTFE.

[0080] Furthermore, in the expansion mold, two spherical electrodes each having a diameter of 12 mm were arranged at a distance of 1 mm. In order to ensure that this distance of 1 mm is maintained even after the expansion has been carried out, the electrodes are fixed in place by means of suitable spacers.

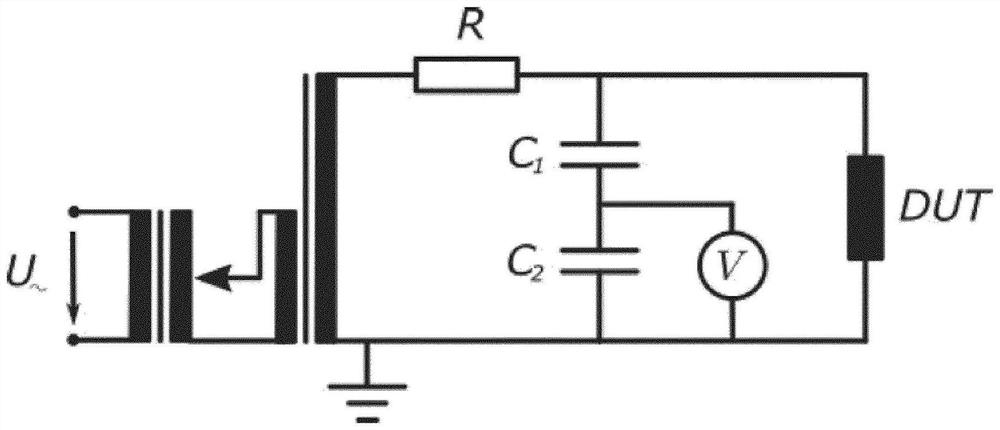

[0081] After expansion to construct the dry syntactic foam in the expansion mold, by using the figure 2 A circuit for breakdown voltage measurement to determine electrical breakdo...

example 2

[0086] This example involves the fabrication of dry syntactic foam directly in the insulation.

[0087] Depend on 551 DET 40 d25 expanded micro hollow spheres (83.9% by volume; bulk density 0.0125g / cm 3 )and 551 DU 40 type of unexpanded micro hollow spheres (16.1% by volume; bulk density 0.5543g / cm 3 ) composed of 0.1g / cm 3 The mixture of bulk densities is expanded at a temperature of 120° C. directly in a cylindrical or annular insulator made of glass fiber reinforced polymer with an inner diameter of 120 mm and a height of 20 mm for a duration of 2 hours.

[0088] During the expansion, the cylinder is closed at each end with a PTFE plate.

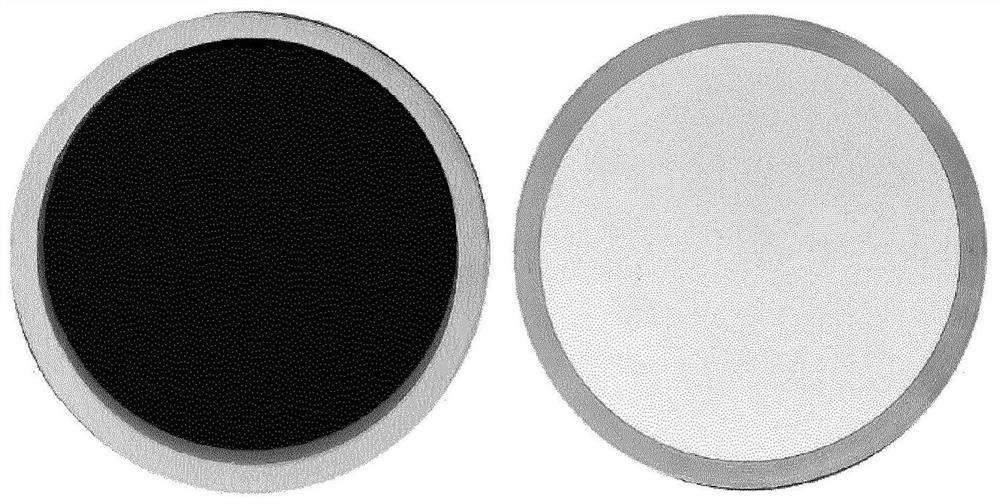

[0089] image 3 A photographic image of the unfilled insulation is shown on the left and a photographic image of the insulation filled with dry composite foam is shown on the right.

[0090] After foaming, the cylindrical insulator was not deformed. This indicates that the expansion pressure is below a critical value that could l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com