Black matte polyimide film and preparation method thereof

A polyimide film, black matte technology, applied in the field of polyimide film, can solve the problems of reducing the electrical breakdown strength of PI film, the difficulty of carbon black dispersion, etc., to achieve the reduction of visible light transmittance, high electrical shock Wear strength, reduce the effect of light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

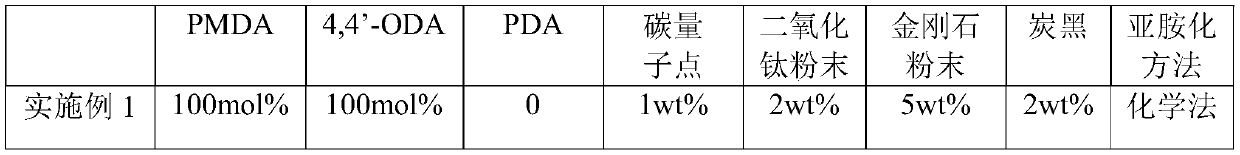

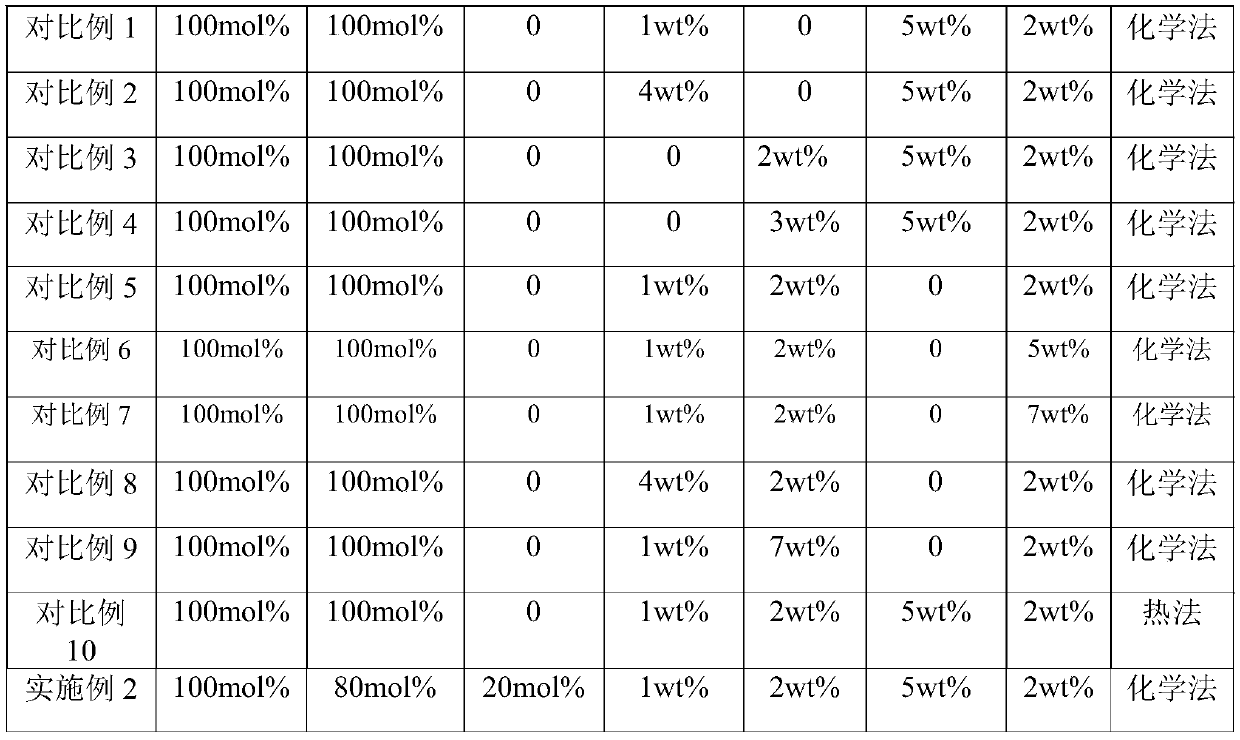

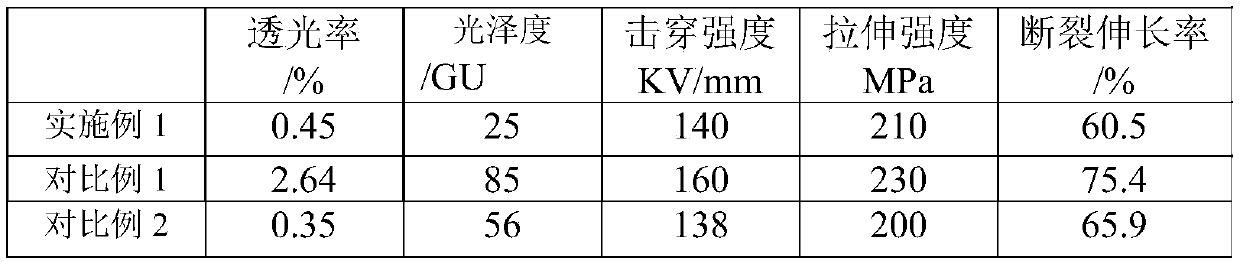

Embodiment 1

[0034] A kind of black matte polyimide film of the present invention, in this polyimide film, mass content is evenly distributed with the carbon quantum dot (average particle diameter 5nm) of 1wt%, the titanium dioxide powder of 2wt% (average particle diameter is 230nm), 5wt% of diamond powder (average particle size of 5000nm) and 2wt% of neutral carbon black.

[0035] The preparation method of the black matt polyimide film of the present embodiment may further comprise the steps:

[0036] (1) Preparation of black inorganic slurry: take 400kg DMF solution by weighing, add 0.3kg polyether polymer (dispersant S-100), after stirring evenly, add 1kg carbon quantum dots (average particle diameter 5nm), 2kg titanium dioxide powder ( Average particle diameter is 230nm), 5kg diamond powder (average particle diameter is 5000nm) and 2kg neutral carbon black (N110 brand carbon black of Cabot Company), then disperse 30min under the high-speed disperser of 3000r / min, place then Grind in a...

Embodiment 2

[0064] A kind of black matte polyimide film of the present invention, in this polyimide film, mass content is evenly distributed with the carbon quantum dot (average particle diameter 5nm) of 1wt%, the titanium dioxide powder of 2wt% (average particle diameter is 230nm), 5wt% of diamond powder (average particle size is 5000nm) and 2wt% of neutral carbon black (N110 grade carbon black of Cabot Corporation).

[0065] The preparation method of the black matt polyimide film of the present embodiment may further comprise the steps:

[0066] (1) Preparation of black inorganic slurry: Weigh 400kg DMF solution, add 0.3kg polyether polymer (dispersant S-100) dispersant, stir well and then add 1kg carbon quantum dots, 2kg titanium dioxide powder, 5kg diamond powder and 2kg of neutral carbon black, then disperse for 30min under a high-speed disperser at 3000r / min, then place it in a sand mill and grind for 2h to obtain a black inorganic slurry;

[0067] (2) Preparation of inorganic fill...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com