A kind of high energy storage density dielectric composite multilayer film and its preparation method

A high energy storage density, multi-layer film technology, applied in the direction of coating, can solve the problem of unsatisfactory effect and other problems, and achieve the effect of remarkable thermal oxidation stability, small dielectric, and good thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] A method for preparing a high energy storage density dielectric composite multilayer film, comprising the following steps:

[0044] (1) Dissolve 0.5-0.8g of PEI into 4-8g of N-methyl-2-pyrrolidone solution, stir with a magnetic stirrer at 40-60°C and 300-700 rpm for 2-8 hours, Get mixed solution A for later use;

[0045] (2) Dissolve 0.4-0.7g of PVDF into 1-3g of N,N-dimethylformamide, stir with a magnetic stirrer at room temperature and at a speed of 500-2000 rpm for 2-8 hours to obtain Mixture B is for later use;

[0046] (3) to AgNO 3 The solution (mass fraction is 3-5%) is slowly added dropwise with NH 3 ·H 2 O solution (mass fraction is 20 ~ 30%) uniform transparent colorless silver ammonia solution; then weigh glucose, deionized water, absolute ethanol and pour them into an empty beaker and stir evenly to form a uniform transparent colorless glucose solution (mass fraction is 4~6%), then the prepared silver ammonia solution, BaTiO 3 Pour the nanoparticles in...

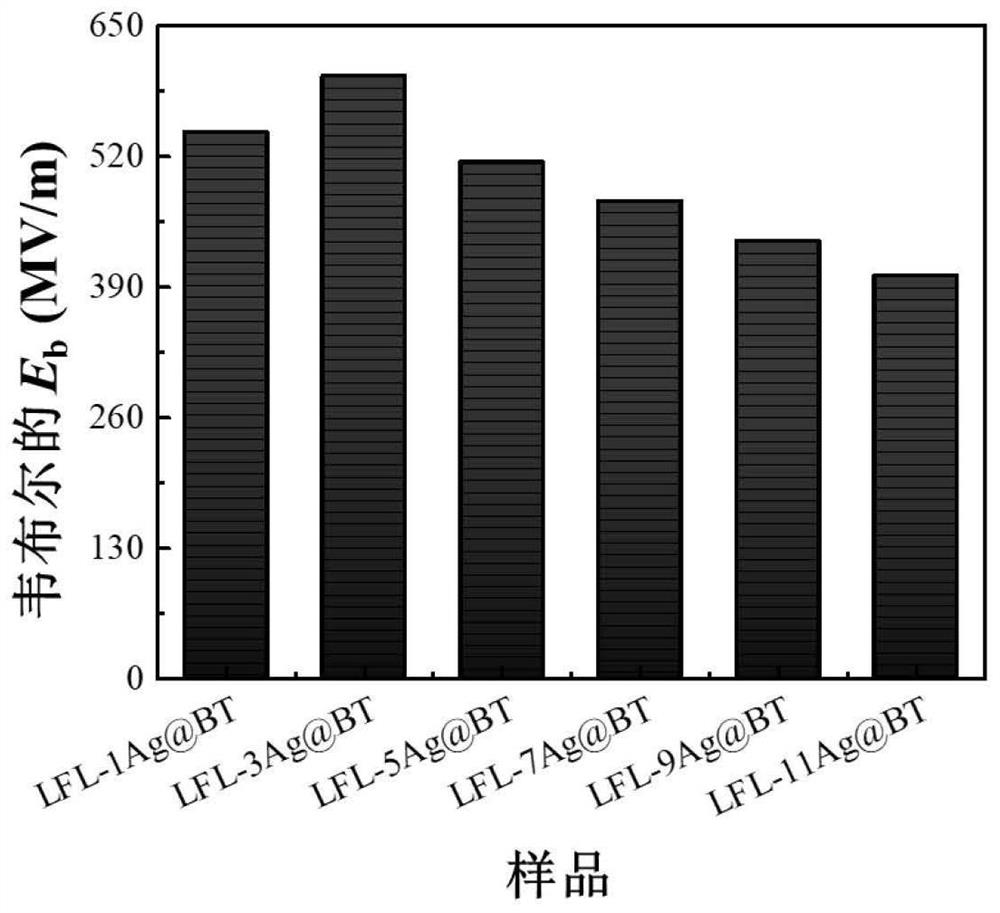

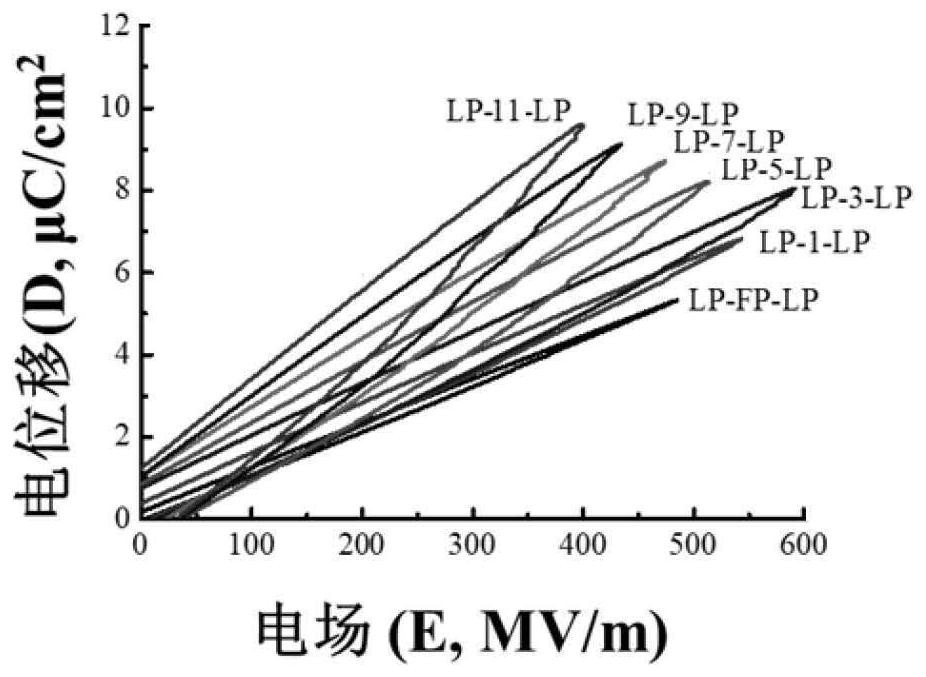

Embodiment 1

[0054] Preparation of Ag@BaTiO 3 The volume fraction of nanoparticles is 1vol% dielectric material PEI-Ag@BT / PVDF-PEI, the steps are as follows:

[0055] (1) Dissolve 0.5g of PEI into 4g of N-methyl-2-pyrrolidone solution, stir with a magnetic stirrer at 40°C and 300 rpm for 2 hours to obtain mixed solution A for later use;

[0056] (2) Dissolve 0.4g of PVDF into 1g of N,N-dimethylformamide, and stir with a magnetic stirrer at room temperature and 500 rpm for 8 hours to obtain a mixed solution B for later use;

[0057] (3) to AgNO 3 Solution (mass fraction is 3%) slowly drop NH 3 ·H 2 O solution (mass fraction is 20%) uniform transparent colorless silver ammonia solution; Then take glucose, deionized water, dehydrated alcohol and pour into empty beaker successively and stir, form uniform transparent colorless glucose solution (mass Fraction is 4%), then the prepared silver ammonia solution, BaTiO 3 The nanoparticles were poured into it; then the mixture was magnetically s...

Embodiment 2

[0064] Preparation of Ag@BaTiO 3 The volume fraction of nanoparticles is 3vol% dielectric material PEI-Ag@BT / PVDF-PEI, the steps are as follows:

[0065] (1) Dissolve 0.6g PEI into 5g of N-methyl-2-pyrrolidone solution, stir with a magnetic stirrer at 50°C and 400 rpm for 4 hours to obtain mixed solution A for later use;

[0066] (2) Dissolve 0.5g of PVDF into 2g of N,N-dimethylformamide, and stir with a magnetic stirrer at room temperature and 1500 rpm for 3 hours to obtain a mixed solution B for later use;

[0067] (3) to AgNO 3 Solution (mass fraction is 4%) slowly drop NH 3 ·H 2 O solution (mass fraction is 25%) uniform transparent colorless silver ammonia solution; Then take glucose, deionized water, absolute ethanol and pour into empty beaker successively and stir, form uniform transparent colorless glucose solution (mass Fraction is 5%), then the prepared silver ammonia solution, BaTiO 3 The nanoparticles were poured into it; then the mixture was magnetically stirr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com