Method for making palladium film on surface of macro-porous carrier

A macroporous carrier and porous carrier technology, applied in separation methods, chemical instruments and methods, membrane technology, etc., can solve problems such as hydrogen resistance, and achieve the effects of avoiding resistance, easy operation, and simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1) Preparation of polyvinyl alcohol (PVA) sol

[0025] Dilute a certain amount of concentrated nitric acid with deionized water into a 0.05mol / L nitric acid aqueous solution, mix polyvinyl alcohol and the above nitric acid aqueous solution according to a solid-to-liquid ratio of 1:30 (g / mL), pour it into a three-necked flask and stir at high speed , with a stirring rate of 500rpm, and kept in a constant temperature water bath at 90°C for 2 hours to completely dissolve the polyvinyl alcohol, leave it to stand, and cool down naturally to obtain a PVA sol;

[0026] 2) PVA modified macroporous carrier surface

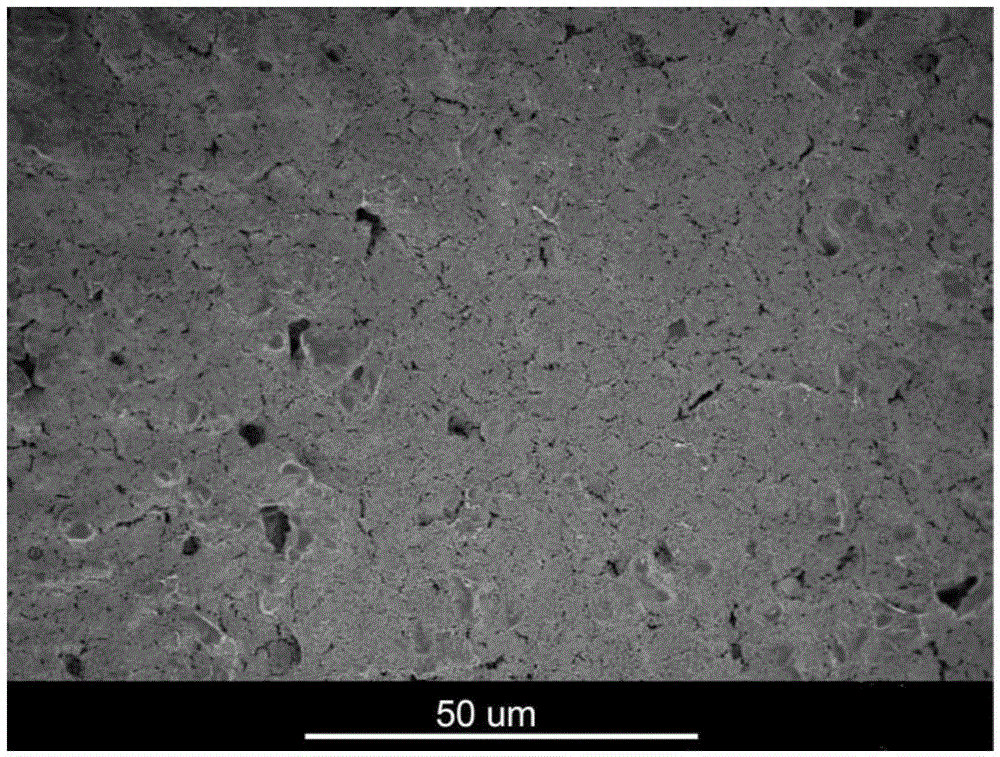

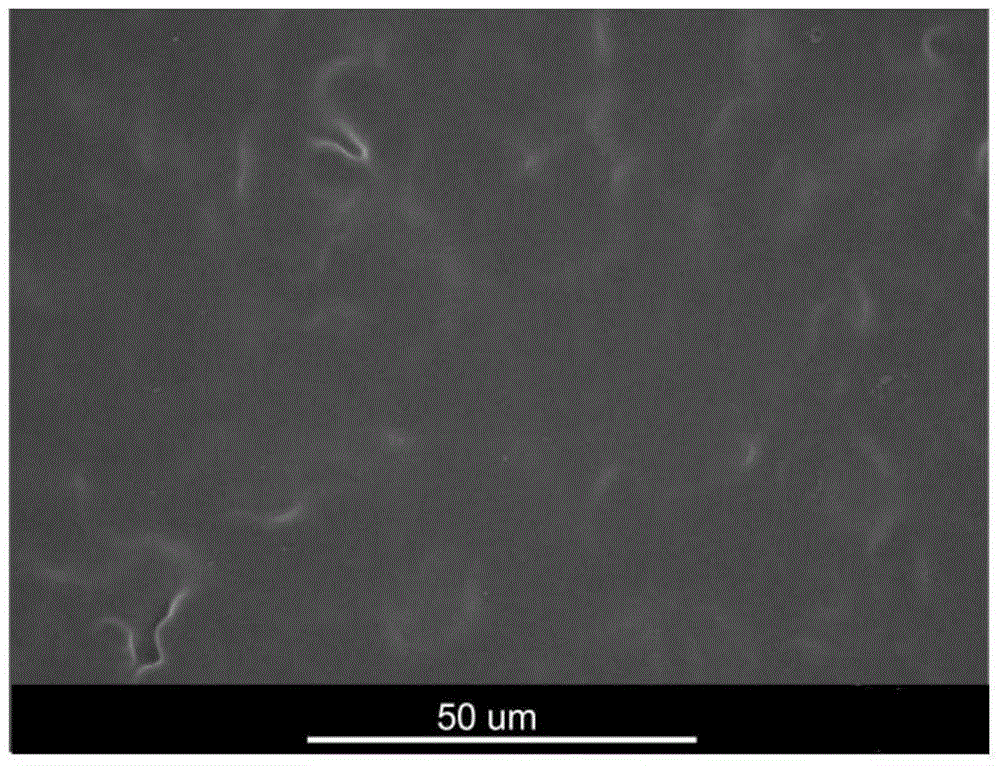

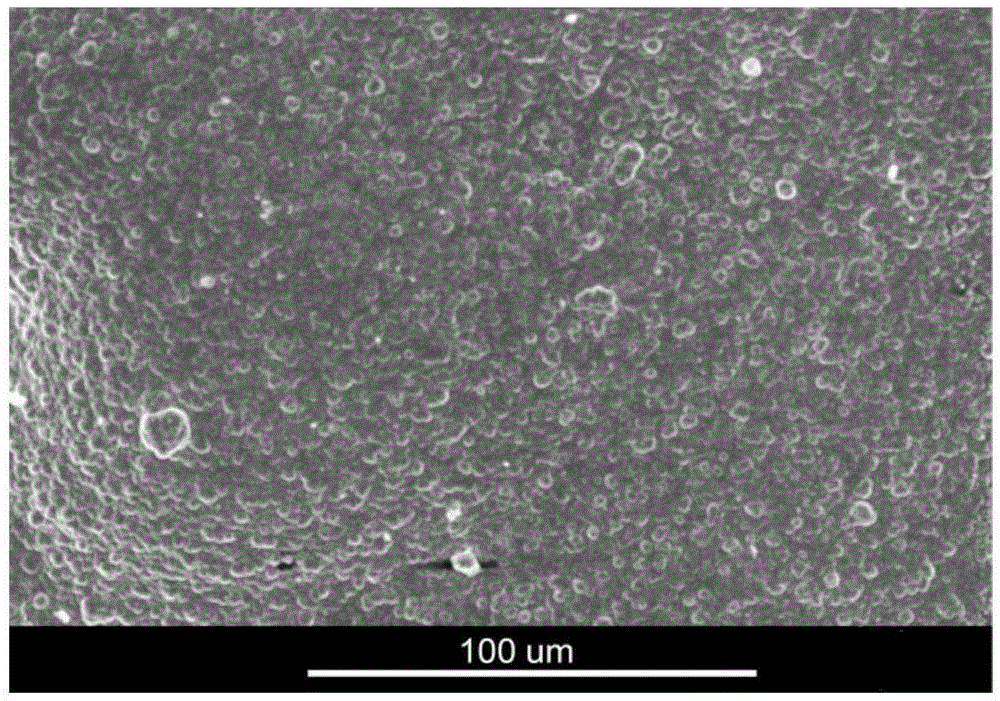

[0027] Such as figure 1 As shown, the porous ceramic carrier with a pore size of 3 μm was vertically immersed in the PVA sol obtained in step 1) for 1 s, then quickly pulled out, and dried with a hair dryer or naturally dried at room temperature. This process was repeated twice to obtain a surface Flat and smooth modified carrier, SEM image of the surface of the ma...

Embodiment 2

[0033] 1) Preparation of polyvinyl alcohol (PVA) sol

[0034] Dilute a certain amount of concentrated nitric acid with deionized water into a 0.02mol / L nitric acid aqueous solution, mix polyvinyl alcohol and the above nitric acid aqueous solution according to a solid-to-liquid ratio of 1:100 (g / mL), pour it into a three-necked flask and stir at high speed , with a stirring rate of 200rpm, and kept in a constant temperature water bath at 50°C for 6 hours to completely dissolve the polyvinyl alcohol, leave it to stand, and cool down naturally to obtain a PVA sol;

[0035] 2) PVA modified macroporous carrier surface

[0036] The porous stainless steel carrier with a pore size of 10 μm was vertically immersed in the PVA sol obtained in step 1) for 10 seconds, then quickly pulled out, and dried with a hair dryer or naturally dried at room temperature. This process was repeated 5 times to obtain a flat and smooth surface. modified carrier;

[0037] 3) The preparation process of th...

Embodiment 3

[0041] 1) Preparation of polyvinyl alcohol (PVA) sol

[0042]Dilute a certain amount of conc , with a stirring rate of 300rpm, and kept in a constant temperature water bath at 70°C for 4 hours to completely dissolve the polyvinyl alcohol, let it stand, and naturally cool down to obtain a PVA sol;

[0043] 2) PVA modified macroporous carrier surface

[0044] Vertically immerse the porous glass carrier with a pore size of 0.5 μm in the PVA sol obtained in step 1) for 5 seconds, then pull it out quickly, and dry it with a hair dryer or dry it naturally at room temperature. This process is repeated 3 times to obtain a flat and smooth surface. Modified carrier;

[0045] 3) the preparation process of palladium membrane is the same as embodiment one, and the coating area and the electroless plating solution volume ratio are 10:120 (cm 2 / cm 3 );

[0046] 4) Removal of the PVA modification layer in the palladium membrane

[0047] Place the palladium film obtained in step 3) in a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com