A self-separated phase mixed conductor three-phase film material and its preparation method and application

A technology of mixed conductor and membrane material, which is applied in the field of self-separated phase mixed conductor three-phase membrane material and its preparation, can solve the problems that the application of gas separation membrane is still blank, and achieve good chemical compatibility and stability, good permeation and permeability. Quantity and stability, the effect of high hydrogen permeation

Active Publication Date: 2022-05-31

QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] However, so far, the preparation of mixed conductor three-phase membrane materials with oxygen ion-proton and electron conduction has not been reported, and the application of gas separation membranes in the medium and high temperature range and hydrogen- or oxygen-related membrane reactors The aspect application is still blank

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

[0045]

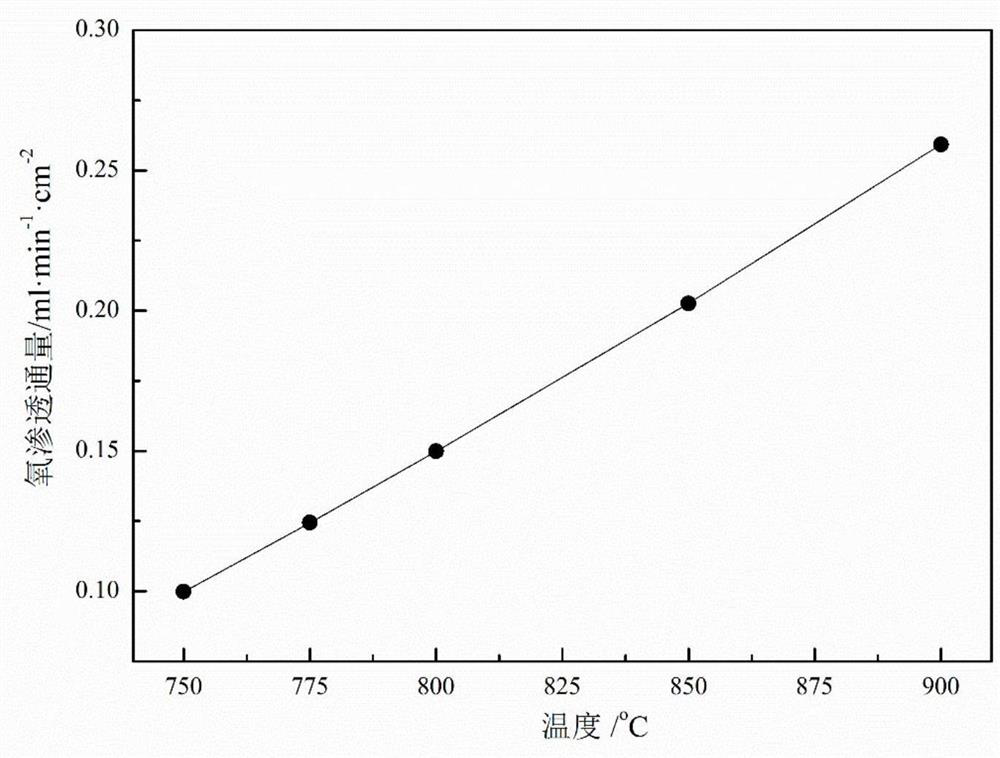

[0047] Calculate the oxygen permeation flux of the membrane according to the above formula (see Figure 3). As can be seen from the figure, as the temperature increases

Embodiment 3

[0051]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

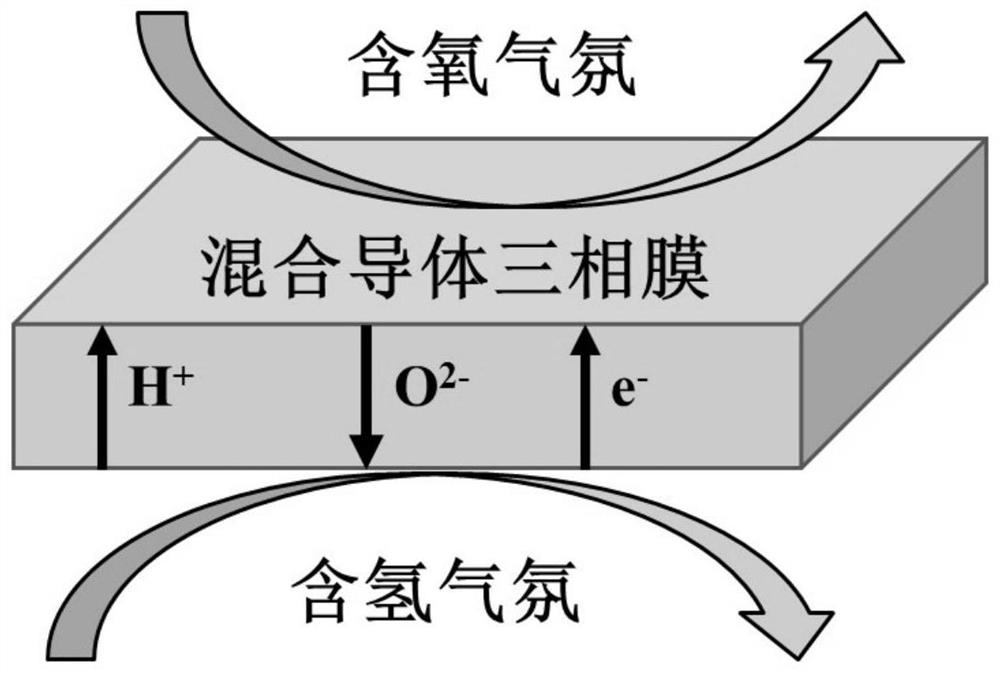

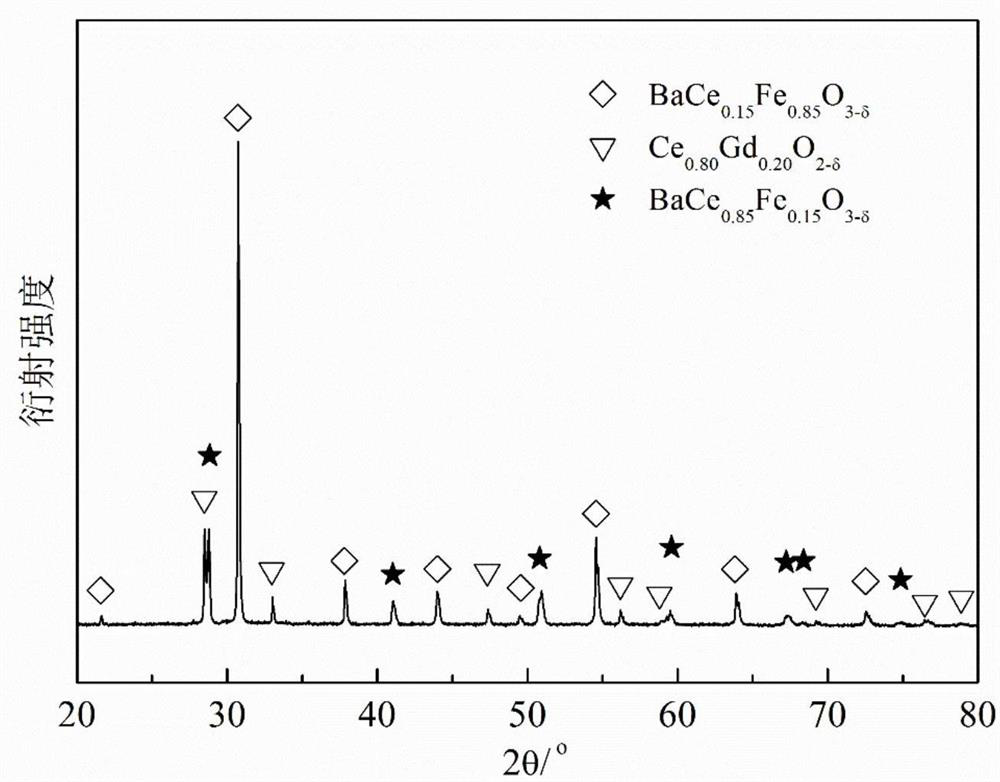

The invention belongs to the field of mixed conductor film materials, in particular to a self-separated phase mixed conductor three-phase film material and its preparation method and application. The membrane material is composed of a perovskite phase mainly conducting protons, a fluorite phase mainly conducting oxygen ions, and a perovskite phase mainly conducting electrons. The mixed conductor three-phase membrane material formed by spontaneous phase separation of the present invention has the characteristics of mixed conduction of protons, electrons and oxygen ions and good chemical compatibility and stability. The mixed conductor three-phase membrane material can be used for oxygen or hydrogen Separation can also be used for electrode materials of proton fuel cells and membrane reactors involving hydrogen or oxygen at high temperatures.

Description

A kind of self-separation mixed conductor three-phase film material and its preparation method and application technical field The invention belongs to the mixed conductor film material field, be specifically related to a kind of self-separation mixed conductor three-phase film material and its Preparation method and application. Background technique Oxygen ion-electron mixed conductor oxygen-permeable membrane is a kind of dense ceramics with both oxygen ion and electron conductivity membrane material. When there is an oxygen partial pressure gradient on both sides of the oxygen permeable membrane, oxygen will pass through the oxygen vacancies in the form of oxygen ions from the high oxygen partial pressure region. Conduction to the low oxygen partial pressure region, while electrons conduct in the opposite direction through hopping between valence metal ions. Therefore, such The membrane material can realize the oxygen transfer process without external circuit, a...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C04B35/50C04B35/26C04B35/622

CPCC04B35/50C04B35/2675C04B35/62218C04B2235/3215C04B2235/3229C04B2235/3224C04B2235/6562C04B2235/6565C04B2235/6567C04B2235/661C04B2235/768C04B2235/6582Y02C20/40

Inventor 江河清夏校良贾露建张艳胡天淼

Owner QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com