Nickel/titanium/vanadium nanowire alloy hydrogen permeability membrane and preparing method and application

A nanowire and hydrogen permeable membrane technology, applied in semi-permeable membrane separation, chemical instruments and methods, membrane technology, etc. The effect of high hydrogen permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

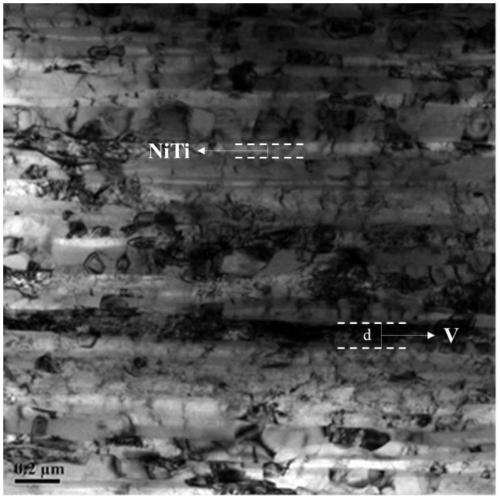

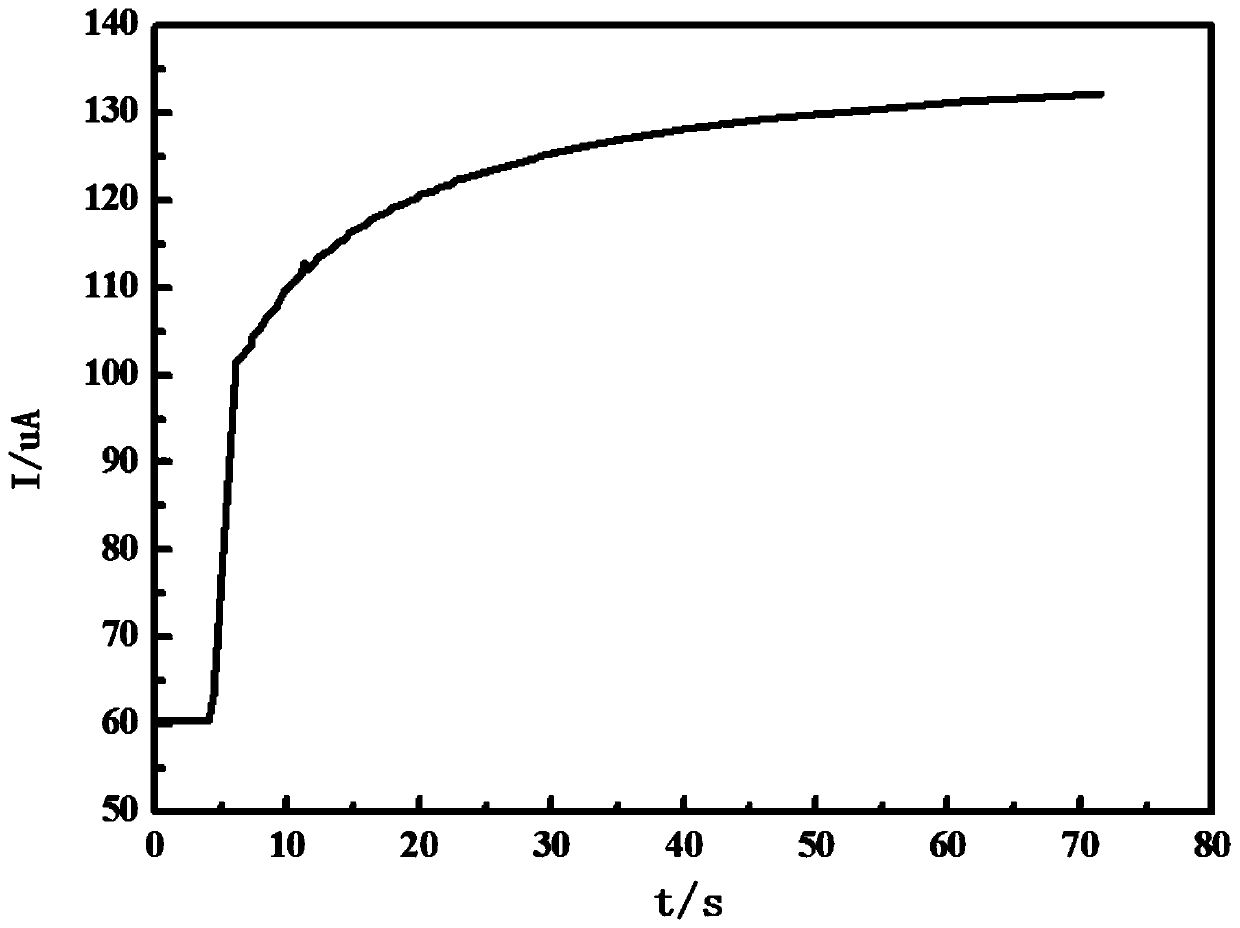

[0030] This embodiment provides a method for preparing a nickel / titanium / vanadium nanowire alloy hydrogen permeable membrane, which includes the following steps:

[0031] (1) Preparation of mixed metal raw materials: take nickel, titanium, vanadium metal powders respectively according to the mass percentage of nickel, titanium, vanadium as 35%: 26%: 39%, and the particle diameters of nickel, titanium, vanadium metal powders are respectively 3mm , to obtain 0.5kg mixed metal powder after mixing evenly;

[0032] (2) Melting: put the mixed metal powder into an electric arc furnace, and melt it at 2000° C. for 5 minutes by induction melting method to obtain nickel / titanium / vanadium alloy ingot;

[0033] (3) Annealing: heat the nickel / titanium / vanadium alloy ingot at 900° C. for 30 minutes, then cool to room temperature with the furnace to complete the annealing;

[0034] (4) Forging: forging the annealed nickel / titanium / vanadium alloy ingot, the forging temperature is 750°C, and ...

Embodiment 2

[0043] This embodiment provides a method for preparing a nickel / titanium / vanadium nanowire alloy hydrogen permeable membrane, which includes the following steps:

[0044] (1) Preparation of mixed metal raw materials: get nickel, titanium, vanadium metal powders respectively according to the mass percentage of nickel, titanium, vanadium 34%: 25%: 38%, the particle diameters of nickel, titanium, vanadium metal powders are respectively 4mm, After mixing evenly, 1kg mixed metal powder is obtained;

[0045] (2) Melting: put the mixed metal powder into a plasma arc furnace, and melt it at 2000° C. for 5 minutes by induction melting method to obtain nickel / titanium / vanadium alloy ingot;

[0046] (3) Annealing: heat the nickel / titanium / vanadium alloy ingot at 900° C. for 30 minutes, then cool to room temperature with the furnace for annealing;

[0047] (4) Forging: forging the annealed nickel / titanium / vanadium alloy ingot, the forging temperature is 800°C, and the forging opening tempe...

Embodiment 3

[0050] This embodiment provides a method for preparing a nickel / titanium / vanadium nanowire alloy hydrogen permeable membrane, which includes the following steps:

[0051] (1) preparation of mixed metal raw materials: get nickel, titanium, vanadium metal powder respectively according to the mass percentage of nickel, titanium, vanadium 35%: 27%: 40%, the particle diameter of nickel, titanium, vanadium metal powder is respectively 5mm, After mixing evenly, 1.5kg mixed metal powder is obtained;

[0052] (2) Melting: put the mixed metal powder into a vacuum induction melting furnace, and melt it at 2000° C. for 5 minutes by induction melting method to obtain nickel / titanium / vanadium alloy ingot;

[0053] (3) Annealing: heat the nickel / titanium / vanadium alloy ingot at 900° C. for 30 minutes, then cool to room temperature with the furnace for annealing;

[0054] (4) Forging: Forging the annealed nickel / titanium / vanadium alloy ingot, the forging temperature is 850°C, and the forging...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com