Chemical plating repairing method for palladium or palladium alloy composite film

A technology of electroless plating and palladium alloy, which is applied in the direction of liquid chemical plating, chemical instruments and methods, membrane technology, etc., can solve the problems of no catalytic activity of electroless plating, decreased repair effect, and membrane rupture, so as to speed up the speed of palladium plating, Improved hydrogen permeation performance and high membrane density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

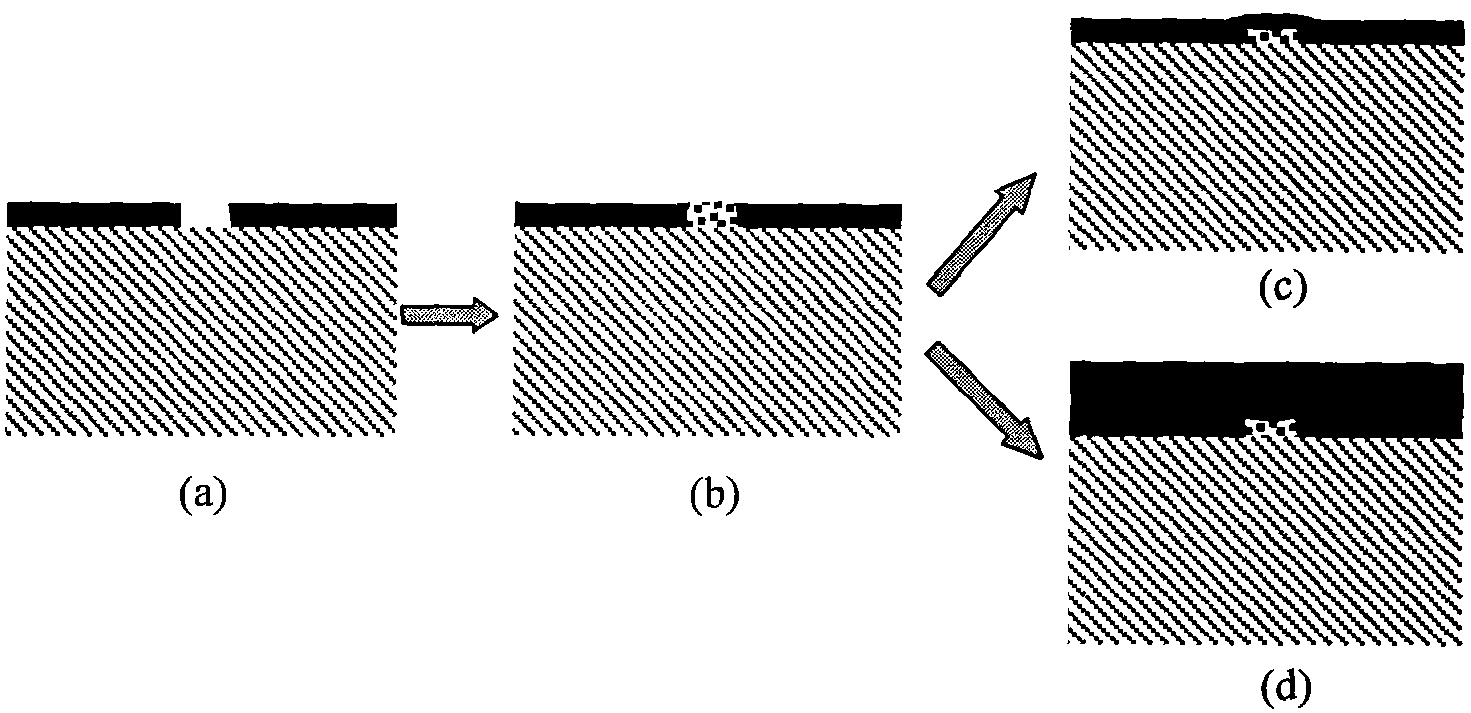

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) The sample used is a defective pure metal palladium membrane tube with an outer diameter of 1.2cm, an inner diameter of 0.7cm, a length of 8.4cm, and a film thickness of 2.5μm. The matrix material is porous Al 2 o 3 . The nitrogen flux is 25 mL / min at a pressure of 1 bar.

[0023] (2) The repair fluid uses Pd(OH) with a palladium ion content of 0.001mol / L 2 For the colloid, refer to the patents of Huang Yan and others for the specific preparation method (Huang Yan, Fan Jingjing, Shu Shili, Hu Xiaojuan. An activation process for non-metallic substrate electroless plating. Chinese patent ZL200710022996.6, 2007).

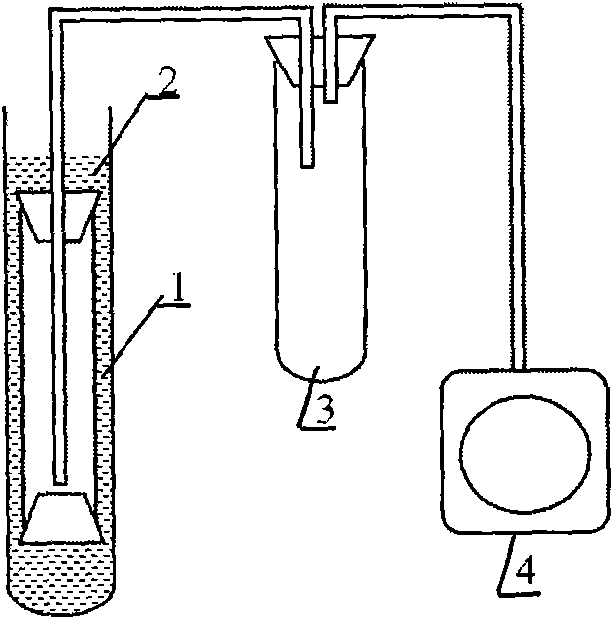

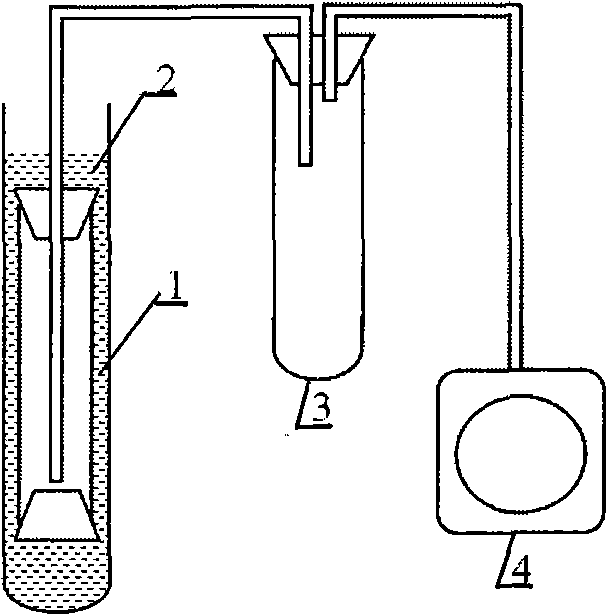

[0024] (3) Repair operations such as figure 2 shown. The two ends of the membrane tube are sealed with silica gel plugs, and the upper end is connected with a vacuum pump, wherein the inner tube penetrates into the vicinity of the bottom of the membrane tube. Immerse the membrane tube in the repair fluid and vacuumize it, and stop the operation as soon...

Embodiment 2

[0028] (1) The matrix material used is Al with an outer diameter of 1.2cm, an inner diameter of 0.75cm, a length of 8.5cm, and an average pore diameter of 0.2μm. 2 o 3 porous ceramic tube. It was washed successively with commercially available detergent solution, tap water, and deionized water. The matrix tube is filled with a soft silicone rubber rod.

[0029] (2) Substrate pretreatment adopts conventional sensitization-activation method. Sensitization solution formula is: SnCl 2 5g / L, concentrated hydrochloric acid 1mL / L; activation solution formula: PdCl 2 0.2g / L, concentrated hydrochloric acid 1mL / L. Dip the substrate in the sensitizing solution and rinse it with deionized water, then dip it in the activation solution and rinse it. Repeat the sensitization-activation operation 4 times, and the surface of the substrate is dark brown.

[0030] (3) Electroless palladium plating. The conditions are the same as step (4) of Example 1, and the thickness of the palladium ...

Embodiment 3

[0036] (1) The sample used is a palladium-silver alloy film tube with relatively large defects, with an outer diameter of 1.2 cm, an inner diameter of 0.8 cm, a length of 8.2 cm, and a film thickness of about 4 μm. Its nitrogen flux is 85 mL / min at a pressure of 1 bar.

[0037] (2) The repair fluid is 2mol / L AgNO 3 solution.

[0038] (3) With the step (3), (4) of embodiment 1.

[0039] (4) The film thickened by 0.8 μm after repair. The membrane tube was alloyed at 650°C for 12 hours under a hydrogen atmosphere, and the nitrogen flux was reduced to 10mL / min at a pressure of 0.1MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com