Preparation method of unsymmetrical composite ceramic hydrogen permeation membrane

A technology of composite ceramics and hydrogen permeable membrane, which is applied in the field of environmental protection materials, can solve the problems of low hydrogen permeable membrane, poor chemical stability and compatibility, etc., to increase hydrogen permeation, good catalytic activity, improve poor stability and The effect of hydrogen permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

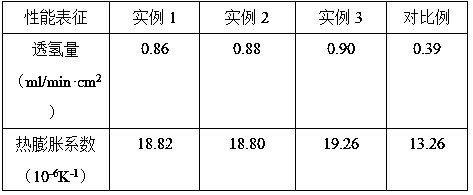

Examples

example 1

[0025] According to the molecular formula Nd 5.5 W 0.5 Mo 0.5 o 11.25-δ (0.05<δ<0.5) Take the oxides of each element and put them into a ball mill for ball milling until the particle size of the powder is 100nm to obtain a mixed powder. Put the mixed powder in a muffle furnace at 800°C Calcined for 10 hours, cooled to room temperature to obtain precursor powder, took 40g nickel nitrate, 50g precursor powder, added to 150mL deionized water, stirred at 300r / min for 20min, then added 15g citric acid, 50g mass fraction was 10% ammonia water, continued After stirring for 1 hour, heat it in a muffle furnace until it spontaneously ignites, cool it to room temperature, transfer it to a grinder, and grind it through a 300-mesh sieve to obtain a composite powder. Take 50g of the composite powder, 30g of N-methylpyrrolidone, 6g of polyethersulfone, and 1g Put polyvinylpyrrolidone into a ball mill, and ball mill it at 300r / min for 8h to obtain a slurry. Take 0.1mol of lanthanum nitrate...

example 2

[0027] According to the molecular formula Nd 5.5 W 0.5 Mo 0.5 o 11.25-δThe amount of elements in (0.05<δ<0.5) Take the oxides of each element and put them into a ball mill for ball milling until the particle size of the powder is 550nm to obtain a mixed powder. Put the mixed powder in a muffle furnace at 850°C Calcined for 11 hours, cooled to room temperature to obtain precursor powder, took 45g nickel nitrate, 55g precursor powder, added 175mL deionized water, stirred at 350r / min for 25min, then added 22g citric acid, 65g mass fraction was 10% ammonia water, continued After stirring for 1.5 hours, place it in a muffle furnace and heat it to spontaneous combustion. After cooling to room temperature, transfer it to a grinder for grinding, and pass through a 300-mesh sieve to obtain a composite powder. Take 55g of the composite powder, 35g of N-methylpyrrolidone, and 7g of polyethersulfone. Put 1.5g of polyvinylpyrrolidone into a ball mill, and ball mill at 330r / min for 9h to...

example 3

[0029] According to the molecular formula Nd 5.5 W 0.5 Mo 0.5 o 11.25-δ The amount of elements in (0.05<δ<0.5) Take the oxides of each element and put them into a ball mill for ball milling until the particle size of the powder is 1000nm to obtain a mixed powder. Put the mixed powder in a muffle furnace at 900°C Calcined for 12 hours, cooled to room temperature to obtain precursor powder, took 50g nickel nitrate, 60g precursor powder, added to 200mL deionized water, stirred at 400r / min for 30min, then added 30g citric acid, 80g mass fraction was 10% ammonia water, continued After stirring for 2 hours, place it in a muffle furnace and heat it to spontaneous combustion. After cooling to room temperature, transfer it to a grinder for grinding, and pass through a 300-mesh sieve to obtain a composite powder. Take 60g of the composite powder, 40g of N-methylpyrrolidone, 8g of polyethersulfone, and 2g Put polyvinylpyrrolidone into a ball mill, and ball mill it at 360r / min for 10h ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com