Boron carbide ceramic material and preparation method thereof

A technology of boron carbide ceramics and carbon paper, which is applied in the field of boron carbide ceramic materials and its preparation, can solve the problems of boron carbide anti-ballistic ceramics that are difficult to apply in large quantities, low strength and toughness, and consumption of boron carbide ceramics, and achieve discharge plasma energy Utilization rate Environmentally friendly, high utilization rate of discharge plasma energy, and less environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

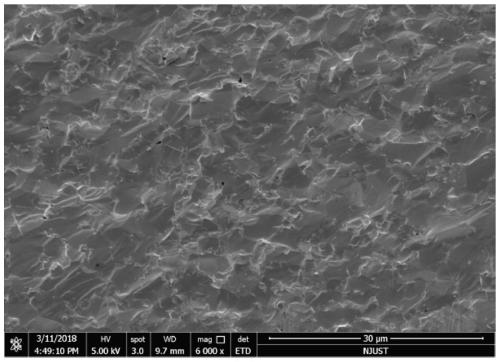

Image

Examples

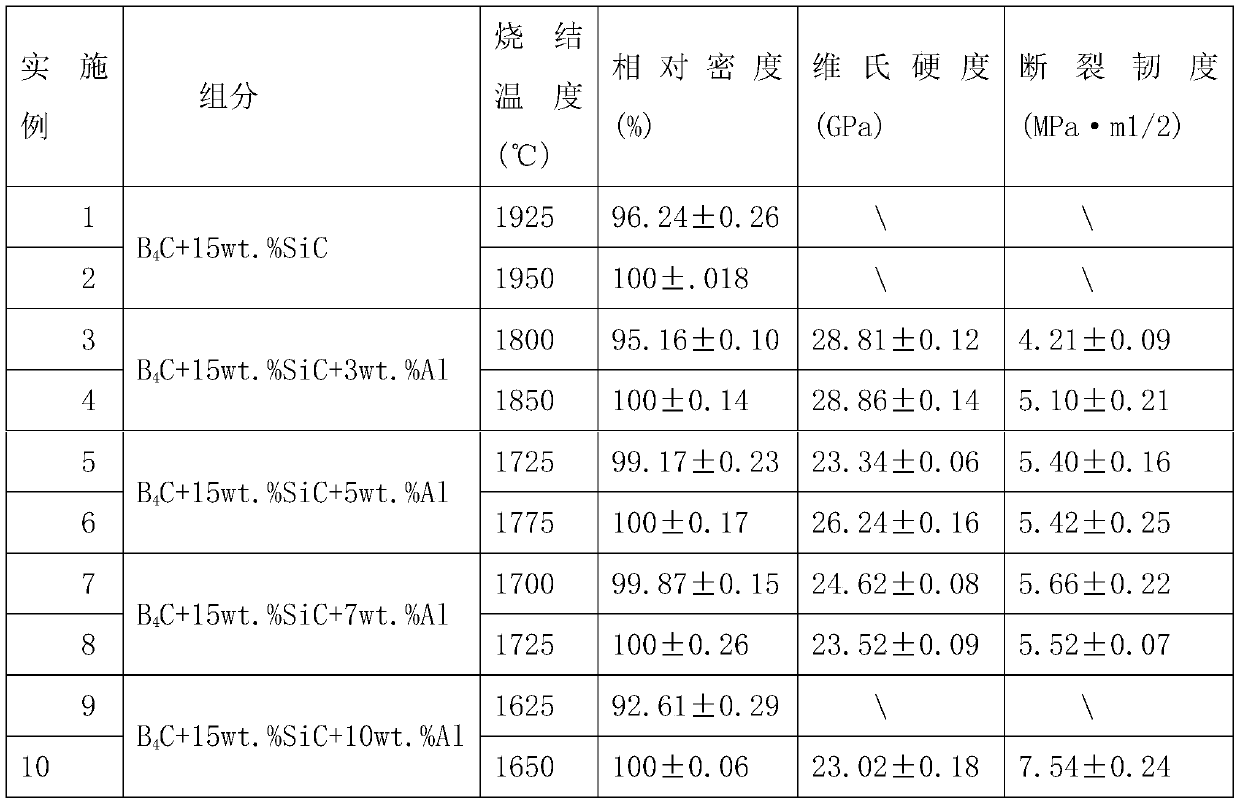

Embodiment 1

[0025] A boron carbide ceramic material and its spark plasma sintering process, specifically: by mass percentage B 4 C85% and SiC15% are used for batching. The prepared mixed powder is placed on an ultrasonic oscillator for 2 hours with absolute ethanol as the medium. After the ultrasonic oscillation is completed, it is dried and ground, and passed through a 100-mesh sieve. The graphite paper of the agent is closely attached to the inner wall of the graphite mold, and the sieved powder is pressed into the graphite mold, pre-pressed at 10MPa, and the pressure is kept for 5 minutes. The outer layer of the graphite mold with the powder is wrapped with carbon felt, and placed in the plasma sintering In the furnace, evacuate the furnace cavity into a vacuum state. When the vacuum gauge shows below 10Pa, then pour in argon gas; set the uniaxial pressure to 30MPa, turn on the plasma power supply for heating, and heat the sample at a heating rate of 100°C / min To 1925 ℃, keep warm for ...

Embodiment 2

[0027] A boron carbide ceramic material and its spark plasma sintering process, specifically: by mass percentage B 4 C 85% and SiC 15% are used for batching, and the prepared mixed powder is placed on an ultrasonic oscillator for 2 hours with absolute ethanol as the medium. The graphite paper of the lubricant is closely attached to the inner wall of the graphite mold, and the sieved powder is pressed into the graphite mold, pre-pressed at 10MPa, and kept under pressure for 5 minutes, the outer layer of the graphite mold containing the powder is wrapped with carbon felt, and placed in the plasma In the sintering furnace, evacuate the furnace cavity into a vacuum state. When the vacuum gauge shows below 10Pa, then pour in argon gas; set the uniaxial pressure to 30MPa, turn on the plasma power supply for heating, and heat the sample at a heating rate of 100°C / min. Heat to 1950°C, keep it warm for 5 minutes, and then cool with the furnace. According to the test, the density of th...

Embodiment 3

[0029] A boron carbide ceramic material and its spark plasma sintering process, specifically: by mass percentage B 4 C82%, SiC15%, and Al3% are used for batching, and the prepared mixed powder is placed on an ultrasonic oscillator for 2 hours with absolute ethanol as the medium. After the ultrasonic oscillation is completed, it is dried and ground. The graphite paper of the boron lubricant lubricant is closely attached to the inner wall of the graphite mold, and the sieved powder is pressed into the graphite mold, pre-pressed at 10MPa, and kept under pressure for 5 minutes, and the outer layer of the graphite mold containing the powder is wrapped with carbon felt, and placed In the plasma sintering furnace, evacuate the furnace cavity into a vacuum state. When the vacuum gauge shows below 10Pa, then pour in argon gas; set the uniaxial pressure to 30MPa, turn on the plasma power supply for heating, and heat up at a rate of 100°C / min. The sample was heated to 1800°C, held for 5 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com