A rapid low-temperature preparation method of y-α-sialon transparent ceramics

A transparent ceramic and fast technology, applied in the field of transparent ceramic material preparation, can solve the problems of high sintering temperature, slow time-consuming, long sintering temperature holding time, etc., to increase the nucleation density, promote the densification process, and prevent microstructure changes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] ① Ingredients: According to the molecular formula Y of Y-α-SiAlON m / 3 Si 12-(m+n) Al m+n o n N 16-n Calculation of Raw Powder Si 3 N 4 , AlN, Al 2 o 3 and Y 2 o 3 The matching ratio, where m=1.2, n=1.1, namely: Si 3 N 4 : 77.3wt.%, AlN: 15.1wt.%, Al 2 o 3 : 0.2wt.%, Y 2 o 3 : 7.4wt.%.

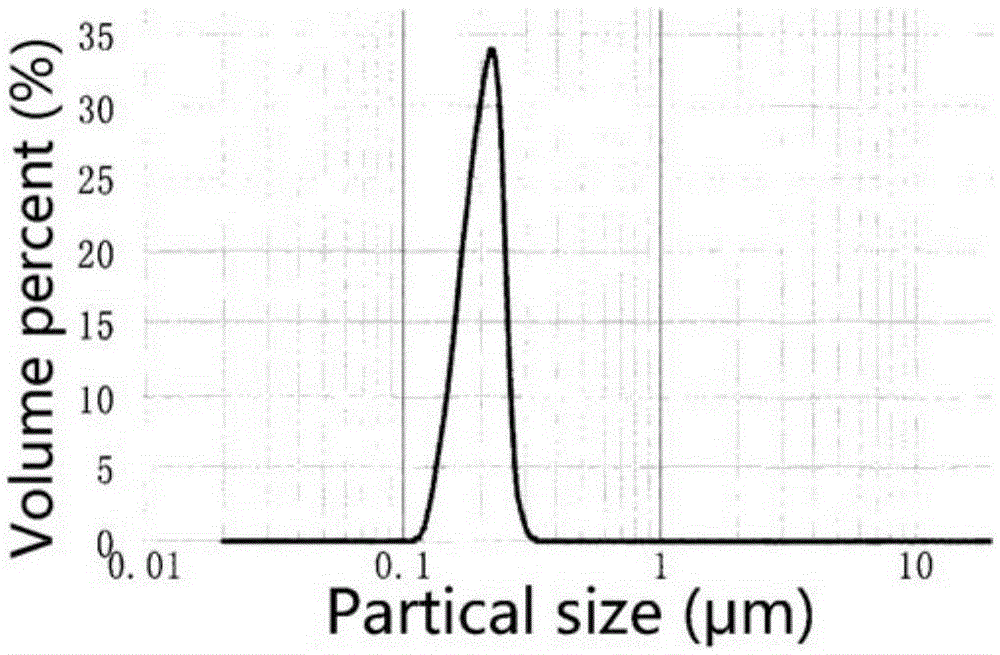

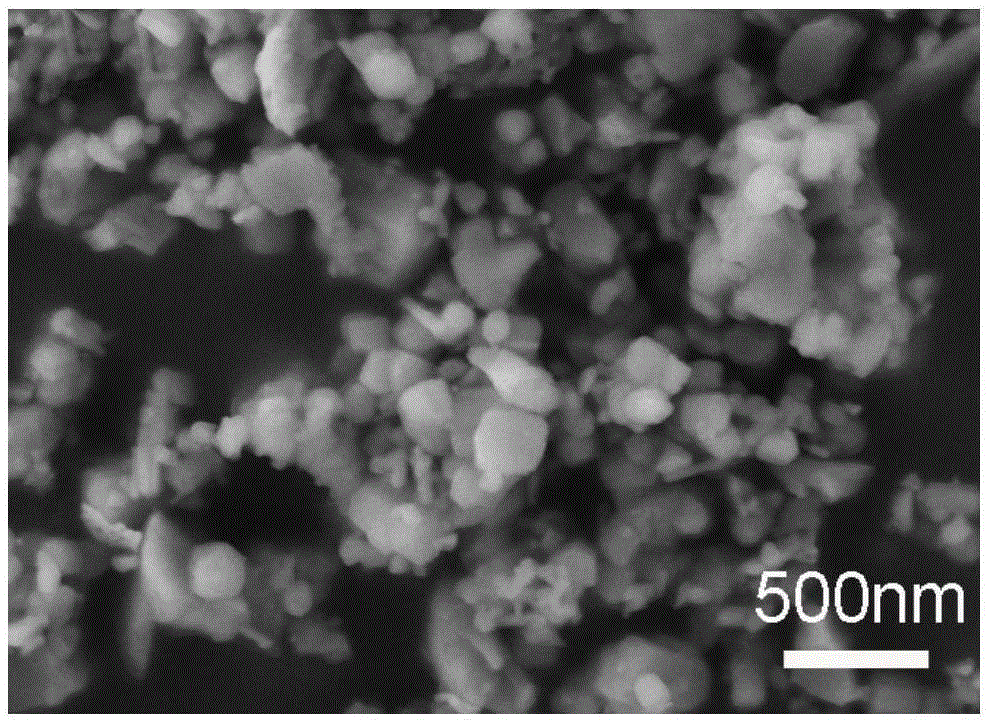

[0030] ②Preparation of superfine mixed powder: Si 3 N 4 , AlN, Al 2 o 3 and Y 2 o 3 Put 40g of the mixed powder into a polytetrafluoroethylene ball mill jar, add 220g of 10mm, 8mm and 5mm silicon nitride balls prepared according to the mass ratio of 1.3:1:1.7, then add 110g of absolute ethanol, and put it on the planetary ball mill with Mix at a speed of 250r / min for 24 hours to refine the mixed powder and mix evenly. The particle size distribution test results of the prepared ultrafine powder are shown in figure 1 , the microscopic morphology of the mixed powder is shown in figure 2 . The average particle size of the obtained powder is 0.21 μm, and the particle...

Embodiment 2

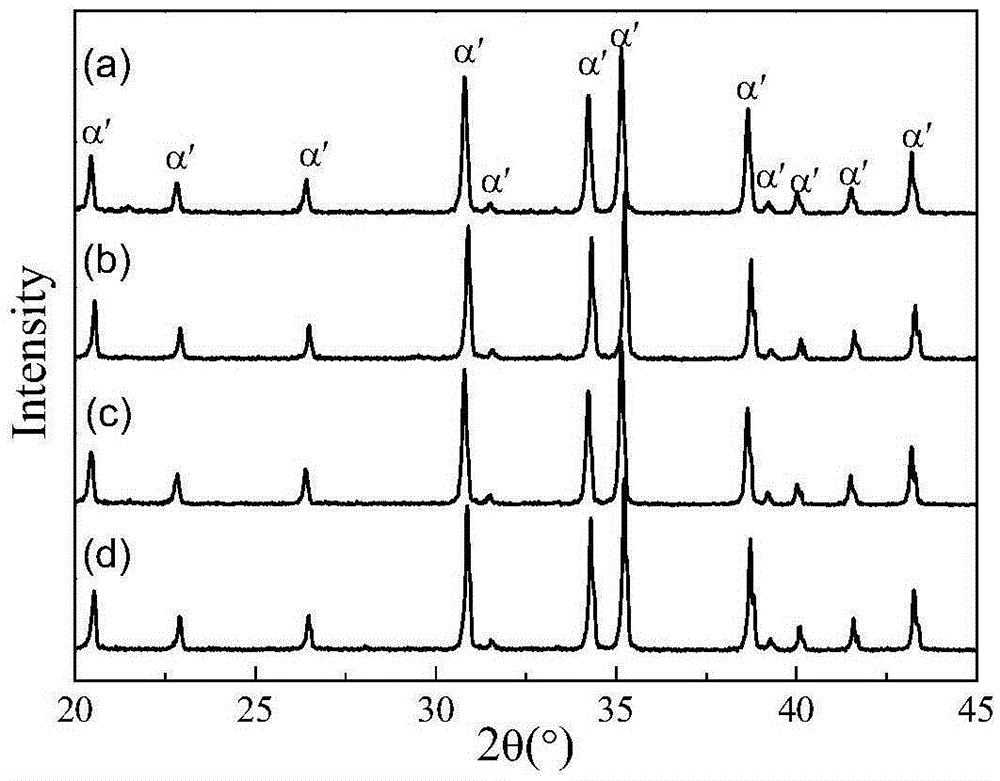

[0038] According to the method of Example 1, the difference is that the sintering temperature is 1800°C, and the densification process is completed when the sample is kept at 1800°C for 2 minutes, and the densification time is 14.7 minutes. down to 1620°C. The density of transparent ceramics is 99.69%; XRD results are shown in image 3 (b), is the pure phase of α-SiAlON; the microstructure see Figure 4 (b), the crystal grain morphology is equiaxed crystal and columnar crystal with small aspect ratio; the photo of 1.2mm thick transparent Y-α-SiAlON ceramic is shown in Figure 5 (b), the words below the sample are clearly visible; the infrared transmittance curve of the 1.2mm thick sample is shown in Image 6 (b), the maximum infrared transmittance is 58%.

Embodiment 3

[0040] According to the method of Example 1, the difference is that the sintering temperature is 1850 ° C, and the densification process has been completed at 1850 ° C. The densification time is 14.3 minutes. After the heat preservation is completed, the maximum pressure of 25 MPa is maintained until the temperature drops to 1650°C. The density of transparent ceramics is 99.70%; XRD results are shown in image 3 (c), is the pure phase of α-SiAlON; the microstructure see Figure 4 (c), the grain morphology is equiaxed crystal and columnar crystal; 1.2mm thick transparent Y-α-SiAlON ceramic photo is shown in Figure 5 (c), the words below the sample are clearly visible; the infrared transmittance curve of the 1.2mm thick sample is shown in Image 6 (c), the maximum infrared transmittance is 58%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com